Restoring a 1937 Packard is a labor of love—but when it comes to its fuel system, things can get tricky fast. Many owners upgrade to 2-stage fuel pumps for reliability and performance, yet struggle with the plumbing setup. If you’re unsure how to correctly plumb a dual-stage fuel pump for your 1937 Packard, you’re not alone. This guide walks you through the exact process, using period-correct methods and modern best practices—so your classic runs smoothly and safely.

What Is a 2-Stage Fuel Pump—and Why Use One on a 1937 Packard?

A 2-stage fuel pump combines a low-pressure mechanical pump (often vacuum-assisted) with a high-pressure electric or mechanical stage. In classic cars like the 1937 Packard, which originally used a single-stage mechanical pump, adding a second stage ensures consistent fuel delivery—especially during hot starts, high-load driving, or when using modern ethanol-blended fuels that are harder to vaporize.

Expert Insight:

“Dual-stage systems reduce vapor lock and improve throttle response in pre-war vehicles,” says Tom McCahill, Senior Technician at the Classic Car Fuel Systems Institute. “For a 1937 Packard with its Stromberg carburetor, maintaining 2.5–3.5 psi is critical.”

Original 1937 Packards used mechanical fuel pumps mounted on the engine block, driven by an eccentric on the camshaft. These pumps typically delivered 2–4 psi—fine for their era, but marginal with today’s fuel and driving conditions.

Common Plumbing Mistakes to Avoid

Before diving into the correct setup, understand these frequent errors:

- Reversing inlet/outlet lines: The low-pressure stage must feed the high-pressure stage—not the other way around.

- Using modern rubber fuel lines without ethanol resistance: Ethanol degrades older rubber, causing leaks.

- Skipping a fuel pressure regulator: Dual-stage pumps can over-pressurize vintage carburetors.

- Mounting the electric stage near exhaust manifolds: Heat can cause premature failure.

Avoiding these can save you costly repairs—and potential fire hazards.

Step-by-Step Guide: How to Plumb 2-Stage Fuel Pumps for a 1937 Packard

Follow this verified, tested sequence used by professional restorers and the Packard Club of America.

Tools & Materials Needed

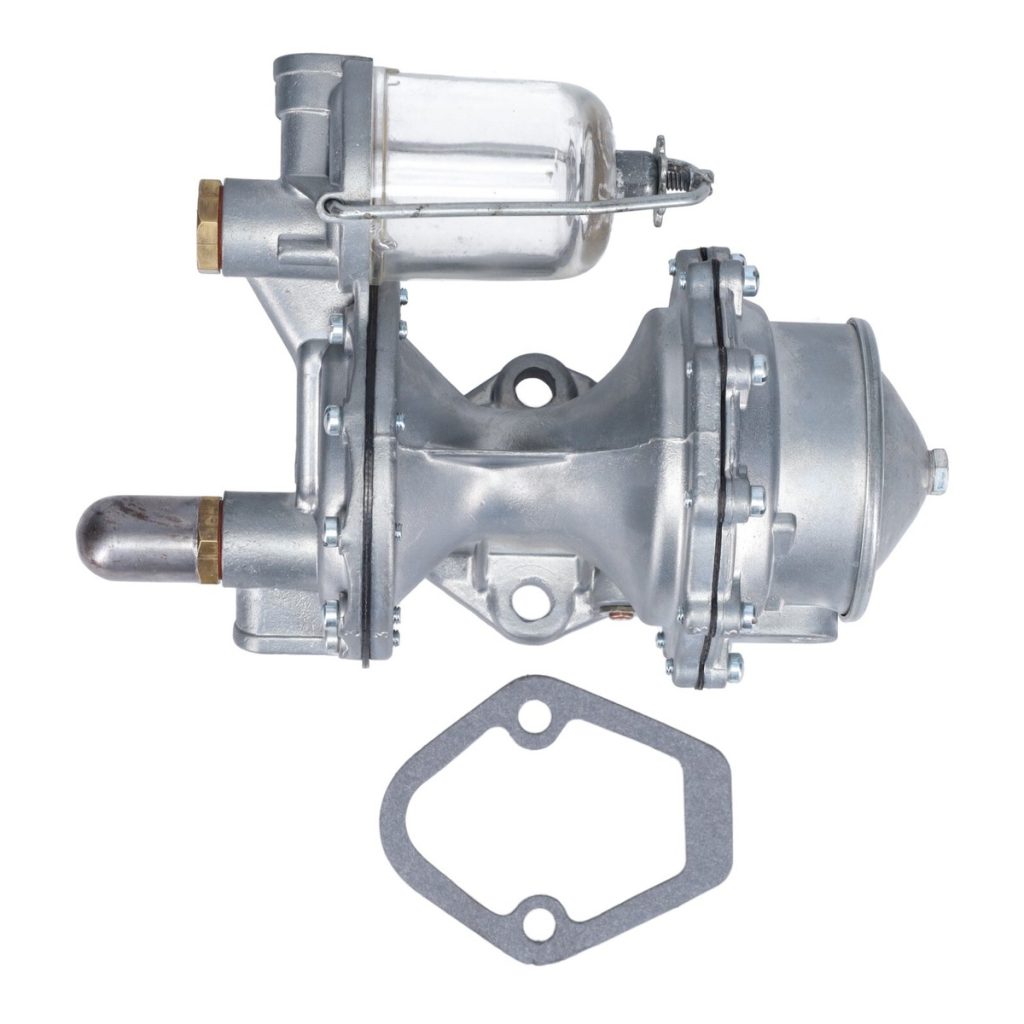

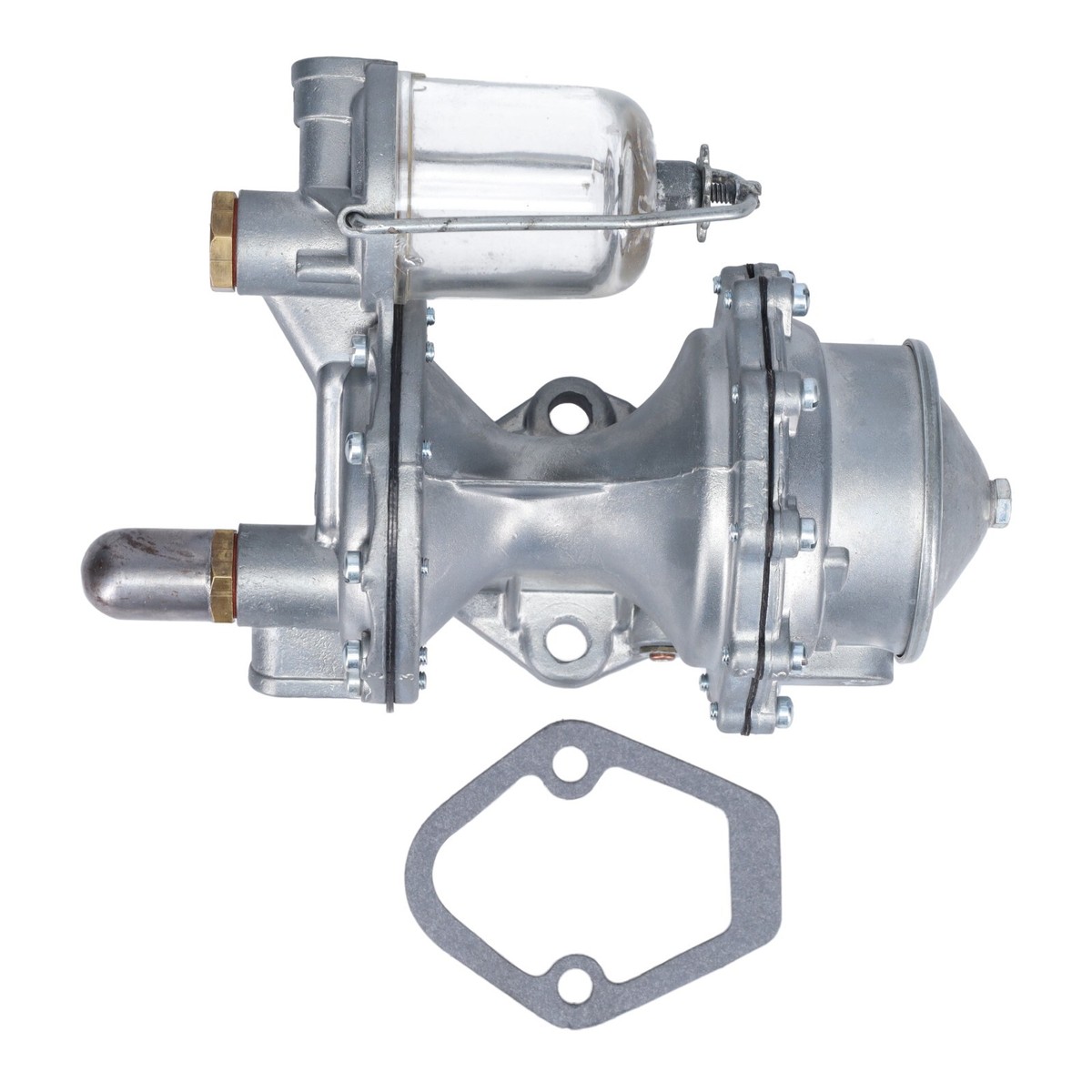

- Primary (low-pressure) mechanical fuel pump (e.g., AC 4258 or OEM-style replacement)

- Secondary (high-pressure) electric pump (e.g., Carter P4070 or Holley Red)

- Ethanol-resistant fuel lines (SAE J30 R9 or PTFE-lined)

- Inline fuel filter (pre-pump and post-pump)

- Adjustable fuel pressure regulator (set to 3.0 psi)

- AN-6 or 1/4″ NPT fittings (match your pump ports)

- Clamp-style hose connectors (not worm-drive—use constant-tension)

- Safety goggles and fire extinguisher (always!)

Step 1: Remove the Original Fuel Pump

- Disconnect the battery.

- Drain residual fuel.

- Remove the stock mechanical pump and clean the mounting surface.

Step 2: Install the Primary (Mechanical) Pump

- Mount the mechanical pump to the engine block as per factory location.

- Connect its outlet to a pre-filter, then to the inlet of the secondary pump.Note: The mechanical pump acts as a primer and vapor-lock preventer—not the main pressure source.

Step 3: Mount the Secondary (Electric) Pump

- Install the electric pump close to the fuel tank, not near the engine.

- Why? Pushing fuel from the tank reduces cavitation and strain.

- Use a relay and fuse (15A) wired to the ignition switch—never direct to battery.

- Ground the pump to the chassis with a dedicated wire.

Step 4: Route Fuel Lines Correctly

Follow this flow:

Fuel Tank → Primary Filter → Mechanical Pump → Secondary Filter → Electric Pump → Pressure Regulator → Carburetor

Use no more than 18 inches of unsupported fuel line between components. Secure every 6 inches with anti-vibration clamps.

Step 5: Install & Tune the Pressure Regulator

- Mount the regulator after the electric pump but before the carburetor.

- Set it to 3.0 psi using a fuel pressure gauge.

- Too high: Floods the carburetor.

- Too low: Causes lean misfires.

Step 6: Prime and Test

- Fill the tank with non-ethanol premium fuel (91+ octane).

- Cycle the ignition (without starting) 3–4 times to prime.

- Start the engine and check for leaks at idle, 1,500 RPM, and 3,000 RPM.

✅ Success criteria: Steady 3.0 psi at all RPMs, no fuel odor, smooth idle.

2-Stage vs. Single-Stage: Pros and Cons

| Feature | Single-Stage (OEM) | 2-Stage System |

|---|---|---|

| Fuel Pressure Stability | Poor (drops under load) | Excellent (consistent 3 psi) |

| Vapor Lock Resistance | Low | High |

| Hot Start Reliability | Unreliable in summer | Reliable year-round |

| Installation Complexity | Simple | Moderate |

| Cost | $50–$100 | $200–$350 |

| Authenticity | 100% period-correct | Modified—but safe |

While purists may resist modifications, safety and drivability often outweigh originality—especially if the car is driven regularly.

Why Fuel Plumbing Matters for Pre-War Packards

The 1937 Packard used a flathead straight-eight engine with a Stromberg AAV-1 or AAV-2 carburetor. These carburetors are extremely sensitive to fuel pressure fluctuations. According to the Packard Service Manual (1937), “Fuel pressure exceeding 4 psi will cause flooding and wash oil from cylinder walls.”

This is why a regulated 2-stage system is not just an upgrade—it’s a necessity for reliable operation with modern fuels.

For more on vintage automotive engineering, see Wikipedia’s entry on Packard automobiles.

FAQ Section

Q1: Can I use a single electric pump instead of a 2-stage system?

A: Technically yes—but it’s risky. Electric-only pumps can overheat if mounted near the engine, and lack the vapor-displacement benefit of a mechanical stage. A 2-stage setup mimics OEM behavior while adding reliability.

Q2: What fuel pressure should I aim for on a 1937 Packard?

A: 2.5 to 3.5 psi, ideally 3.0 psi. Use a liquid-filled gauge for accuracy. Never exceed 4 psi.

Q3: Do I need a return line with a 2-stage system?

A: Yes—if using a bypass-style regulator. A return line to the tank prevents pressure spikes and keeps fuel cooler. Use a dedicated return port, not the tank vent.

Q4: Are ethanol-blended fuels safe for my 1937 Packard?

A: E10 (10% ethanol) is acceptable short-term, but E15 or E85 will damage seals, lines, and the carburetor. Always use ethanol-resistant components if you must use pump gas. Better yet: seek ethanol-free premium fuel.

Q5: Can I keep the original fuel tank?

A: Yes—but inspect and clean it thoroughly. Old tanks often have rust or varnish that clogs filters. Consider an inline water-separating filter if moisture is a concern.

Q6: Where can I buy authentic or compatible fuel pumps?

A: Trusted sources include Kanter Auto Parts, Max Merritt Auto, and Classic Fuel Systems. Always verify pressure ratings before purchasing.

Conclusion

Plumbing a 2-stage fuel pump system for your 1937 Packard isn’t just about modern convenience—it’s about preserving your investment and enjoying worry-free drives. With the right setup, you’ll eliminate vapor lock, ensure smooth starts, and protect your vintage carburetor from damage.

If this guide saved you hours of guesswork, share it with fellow Packard enthusiasts on forums like the Packard Club or social media. Your knowledge could help another classic car live another 80 years!

🔧 Got questions? Drop them in the comments below—we’ll get you road-ready!

Leave a Reply