Choosing the right valve for your plumbing system can feel overwhelming—especially when you’re caught between popular options like gate valves and ball valves. Both have their strengths, but if you need precise flow control, full-bore flow, or long-term reliability in high-pressure systems, the advantage of using gate valve over ball valve in plumbing becomes clear. In this guide, we’ll break down exactly why and when a gate valve might be your best bet—backed by industry standards, real-world use cases, and expert insights.

What Is the Main Difference Between Gate Valves and Ball Valves?

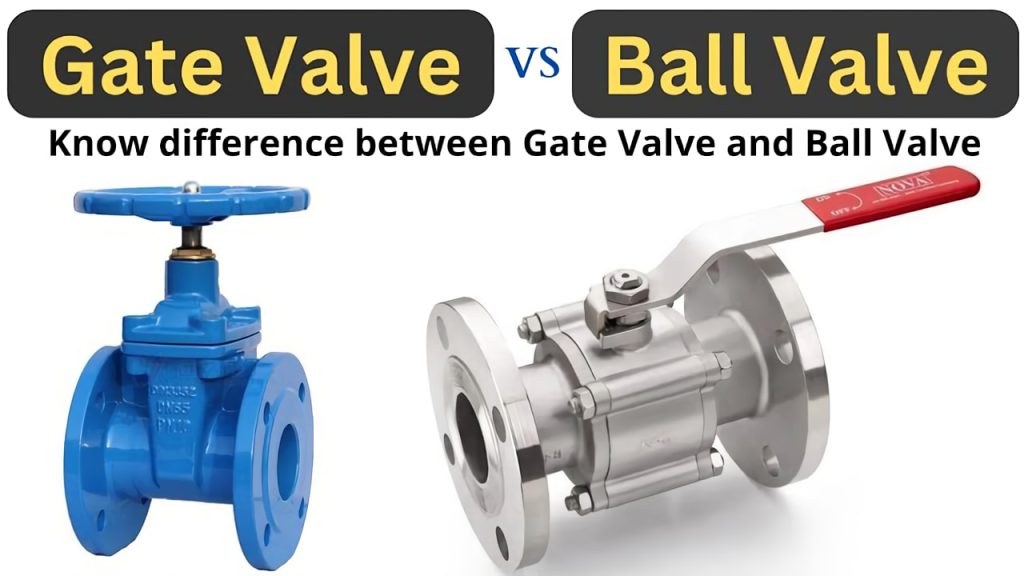

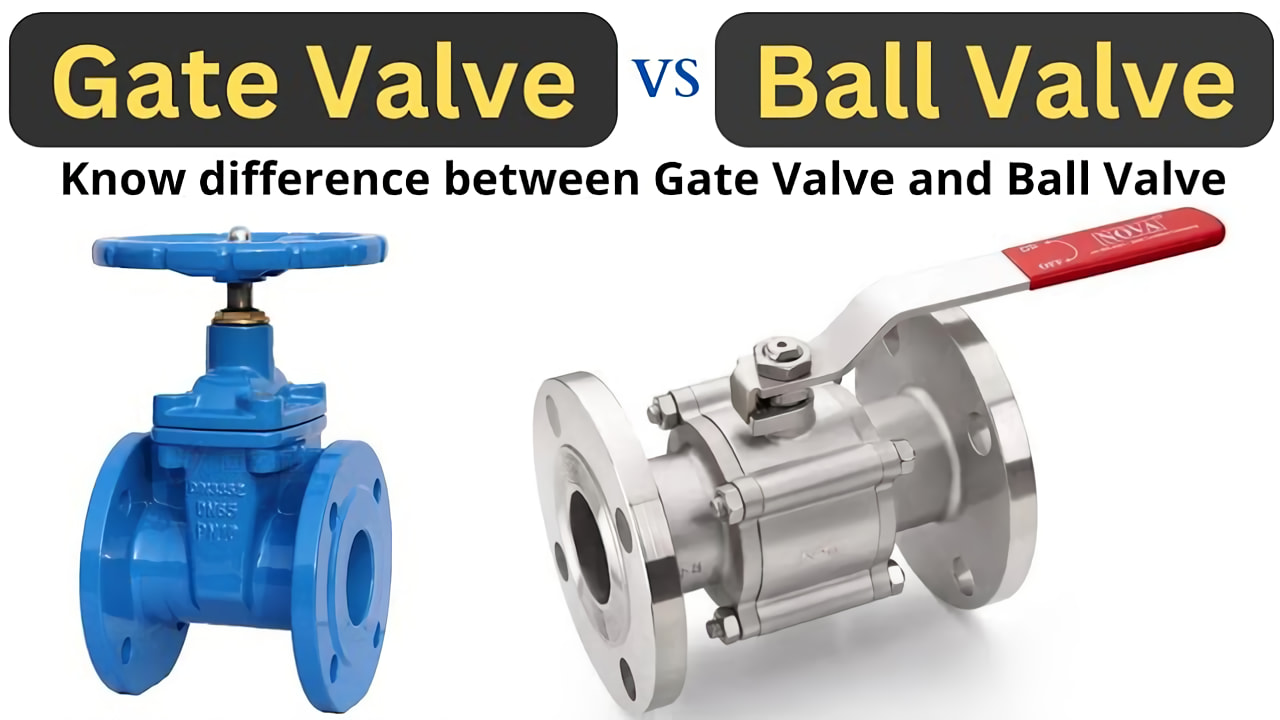

Before diving into advantages, it’s essential to understand the core functional differences:

- Gate valves operate with a sliding gate mechanism that moves vertically to start or stop flow. They’re designed for full-on or full-off service, not throttling.

- Ball valves use a rotating ball with a bore; a quarter-turn opens or closes the flow. They excel in quick shutoff applications.

While ball valves dominate residential settings due to their speed and compact size, gate valves remain the gold standard in industrial and municipal plumbing—here’s why.

💡 According to the American Society of Mechanical Engineers (ASME), gate valves are preferred in systems requiring minimal pressure drop and unobstructed flow paths—critical in water mains and fire protection lines.

Why Choose a Gate Valve? 5 Key Advantages Over Ball Valves

1. Unrestricted Full-Bore Flow When Fully Open

When a gate valve is fully open, the gate retracts entirely into the bonnet, creating a straight-through flow path with virtually no obstruction. This results in:

- Near-zero pressure drop

- Reduced turbulence and erosion

- Ideal for high-flow applications like city water distribution or fire suppression systems

In contrast, even full-port ball valves have a slight flow restriction due to the internal cavity of the ball. Standard (reduced-port) ball valves worsen this issue—increasing energy costs over time in large-scale systems.

2. Superior Performance in High-Pressure & High-Temperature Systems

Gate valves are commonly rated for Class 150 to Class 2500 pressure classes and can handle temperatures from -20°F to over 1,000°F, depending on materials (e.g., cast steel, stainless steel).

Ball valves, while robust, face limitations:

- PTFE (Teflon) seals degrade above 450°F

- Thermal expansion can distort the ball, leading to leaks

📊 A 2023 study by the Fluid Sealing Association found that gate valves in oil & gas pipelines had a 22% lower failure rate over 10 years compared to ball valves in similar high-temp environments.

3. Longer Service Life in Infrequently Operated Systems

If your valve stays open for months or years (e.g., in main water lines or backup systems), gate valves outperform ball valves in longevity:

- No elastomeric seals to dry out or crack

- Metal-to-metal seating resists degradation

- Less prone to “sticking” after long dormancy

Ball valves, especially those with soft seats, can suffer from seat compression set or lubricant drying, making them hard to turn or leak when reopened.

4. Better Compatibility with Slurries and Viscous Fluids

Gate valves handle dirty water, sludge, or semi-solid media more effectively. The straight-through design prevents clogging, and the gate can “scrape” debris as it closes.

Ball valves? Their internal cavities trap particles, leading to:

- Seal damage

- Incomplete shutoff

- Operational jamming

This is why wastewater treatment plants and mining operations overwhelmingly use gate valves for slurry lines.

5. Lower Risk of Water Hammer in Large-Diameter Lines

Because gate valves close slowly (requiring multiple turns), they minimize hydraulic shock (water hammer) in large pipes (>2 inches). Ball valves snap shut instantly—a major risk in high-velocity systems.

⚠️ Per the National Fire Protection Association (NFPA), sudden shutoff valves can generate pressure spikes exceeding 10x normal—potentially rupturing pipes. Gate valves mitigate this risk.

Learn more about valve types and fluid dynamics on Wikipedia.

Gate Valve vs Ball Valve: Quick Comparison Table

| Feature | Gate Valve | Ball Valve |

|---|---|---|

| Operation Speed | Slow (multi-turn) | Fast (¼ turn) |

| Flow When Open | Full, unobstructed | Slight restriction (even full-port) |

| Best For | On/Off, high-flow, high-pressure | Quick shutoff, frequent operation |

| Throttling Capability | ❌ Not recommended | ⚠️ Limited (causes cavitation) |

| Durability (Dormant) | ✅ Excellent | ❌ Seals may degrade |

| Slurry/Dirty Media | ✅ Handles well | ❌ Prone to clogging |

| Water Hammer Risk | Low | High |

When Should You Not Use a Gate Valve?

Despite its strengths, gate valves aren’t universal. Avoid them if:

- You need frequent on/off cycling (gate threads wear quickly)

- Precise flow regulation is required (use a globe valve instead)

- Space is limited (gate valves are taller due to rising stems)

In residential kitchens or bathrooms, ball valves win for convenience. But for main lines, industrial processes, or fire hydrants? Gate valves shine.

How to Install a Gate Valve Correctly (Step-by-Step)

Improper installation undermines even the best valve. Follow these steps:

- Shut off main water supply and drain the line.

- Verify valve orientation: Gate valves are bi-directional, but check manufacturer specs.

- Clean pipe threads thoroughly—debris causes leaks.

- Use Teflon tape or pipe dope on male threads (2–3 wraps clockwise).

- Hand-tighten first, then use a wrench for 1–1.5 additional turns (don’t overtighten).

- Slowly reopen the main supply and check for leaks at joints.

- Operate the valve 2–3 times to seat the gate properly.

✅ Pro tip: Install gate valves in the fully open position for main lines—never partially open.

FAQ: Gate Valve vs Ball Valve in Plumbing

Q1: Can I use a gate valve for hot water lines?

A: Yes—especially in main supply lines. Choose a bronze or stainless steel gate valve rated for your system’s temperature (typically up to 250°F for residential).

Q2: Why do plumbers sometimes replace gate valves with ball valves?

A: In branch lines (e.g., under sinks), ball valves offer faster shutoff and take less space. But for main shutoffs, many codes now require OS&Y (Outside Screw & Yoke) gate valves for reliability.

Q3: Do gate valves leak more than ball valves?

A: Not if maintained properly. Older gate valves with worn seats can leak, but modern wedge-style or flexible wedge gates provide tight shutoff. Ball valves leak when seats degrade—especially after long idle periods.

Q4: Are gate valves more expensive?

A: Initially, yes—by 20–40%. But over 10–20 years, their durability in critical applications often makes them more cost-effective.

Q5: Can I partially open a gate valve to control flow?

A: Never. Partial opening causes vibration, noise, and erosion of the gate and seat. Gate valves are strictly for on/off use.

Q6: What’s the lifespan of a gate valve?

A: In municipal systems, gate valves regularly last 30–50 years with minimal maintenance. Ball valves average 15–25 years under similar conditions.

Conclusion: Make the Smart Choice for Your Plumbing System

The advantage of using gate valve over ball valve in plumbing isn’t about declaring one “better”—it’s about matching the valve to the application. For main lines, high-flow, high-pressure, or infrequently operated systems, gate valves deliver unmatched reliability, flow efficiency, and longevity.

If you’re upgrading a home shutoff or installing a new irrigation main, consider a gate valve for peace of mind that lasts decades. And if this guide helped you decide, share it with a fellow DIYer or contractor—they’ll thank you later!

🔗 Found this helpful? Pin it on Pinterest, tweet it, or send it to your plumber!

Remember: The right valve today prevents costly leaks tomorrow.

Leave a Reply