Replacing your brake master cylinder or adding a proportioning valve? You’re not alone—many DIYers and performance enthusiasts tackle this to improve pedal feel, balance, and overall braking efficiency. But brake line plumbing with a new master cylinder and proportioning valve can quickly become confusing if you don’t understand fluid dynamics, pressure distribution, or OEM vs. aftermarket setups. Done right, your car stops smoother and safer. Done wrong? You risk brake fade, uneven wear, or worse—total failure. Let’s walk through everything you need to know, step by step.

Why Is Proper Brake Line Plumbing Critical?

Brake systems rely on hydraulic pressure to transfer your foot’s force into clamping force at the wheels. When you install a new master cylinder or a proportioning valve, even a minor mistake in routing or bleeding can compromise your entire braking system.

According to the National Highway Traffic Safety Administration (NHTSA), nearly 22% of vehicle crashes involve brake-related issues, many stemming from improper maintenance or modification. That’s why understanding your system’s hydraulic balance is non-negotiable.

A properly plumbed system ensures:

- Consistent front-to-rear brake bias

- Reduced risk of rear wheel lockup (especially in lighter or lowered vehicles)

- Optimal pedal feel and responsiveness

Pro Tip: Always verify your vehicle’s original brake bias specifications before making changes. Deviating too far can void warranties or fail safety inspections.

What Does a Proportioning Valve Do?

A brake proportioning valve regulates hydraulic pressure sent to the rear brakes. In most stock vehicles, it’s built into the combination valve. In custom or performance builds, an adjustable proportioning valve is added to fine-tune pressure.

How it works:

During hard braking, weight transfers to the front wheels, reducing rear tire grip. Without modulation, rear brakes can lock up prematurely. The proportioning valve reduces rear circuit pressure once a preset threshold is reached—typically around 200–600 psi, depending on setup.

Expert Insight: “In 90% of modified street cars I’ve worked on, the rear brakes are over-pressurized. An adjustable proportioning valve isn’t a luxury—it’s a necessity for safe, predictable stopping.”

— Mark D., ASE Master Technician & Brake Specialist (20+ years)

For more on hydraulic principles, see Hydraulic Braking Systems on Wikipedia.

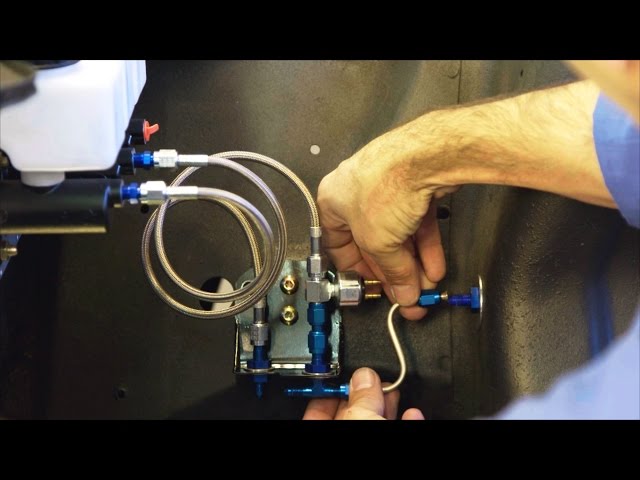

Step-by-Step: Plumbing Brake Lines with a New Master Cylinder & Proportioning Valve

Follow these steps carefully. Always wear safety glasses and work in a well-ventilated area. Brake fluid is corrosive and toxic.

Tools & Materials Needed:

- New master cylinder (correct bore size for your system)

- Adjustable brake proportioning valve (e.g., Wilwood or Earle Williams)

- DOT 4 or DOT 5.1 brake fluid (check manufacturer specs)

- Double-flare tubing cutter & flaring tool (for steel lines)

- AN fittings or OEM-style connectors (as applicable)

- Brake bleeding kit (vacuum or pressure type)

- Torque wrench (critical for banjo bolts)

Step 1: Choose the Right Master Cylinder Bore Size

- Smaller bore (e.g., 7/8″): Higher pressure, softer pedal (ideal for disc/disc systems with manual brakes).

- Larger bore (e.g., 1″): Lower pressure, firmer pedal (suited for power-assisted or drum rear setups).

Mismatched bore size is the #1 cause of poor pedal feel after upgrades.

Step 2: Mount the Master Cylinder Securely

- Bolt to firewall with manufacturer-recommended torque (usually 18–25 ft-lbs).

- Ensure no binding or stress on the pushrod.

Step 3: Route Brake Lines Correctly

Typical plumbing sequence:

- Front outlet of master → Front calipers (direct or via distribution block).

- Rear outlet of master → Input port of proportioning valve.

- Output port of proportioning valve → Rear calipers or wheel cylinders.

Important: Never plumb the proportioning valve into the front circuit—this can cause dangerous front brake underperformance.

Step 4: Use Proper Fittings & Avoid Kinks

- Use 37° AN fittings for performance builds; OEM double-flare for stock replacements.

- Keep lines away from exhaust, suspension travel, and sharp edges.

- Minimum bend radius: 2x the tube diameter (e.g., 0.5″ tube = 1″ radius).

Step 5: Bench-Bleed the Master Cylinder First

- Fill reservoir, attach short hoses from outlets back into reservoir.

- Depress piston slowly 10–15 times until no air bubbles appear.

- Do not skip this step—air trapped here causes a spongy pedal that’s hard to bleed later.

Step 6: Bleed the System in Correct Order

Standard sequence: Right Rear → Left Rear → Right Front → Left Front

- Use fresh brake fluid (never reuse bled fluid).

- Bleed until fluid runs clear and bubble-free (typically 15–20 pumps per corner).

- Keep reservoir at least ⅓ full at all times to prevent air ingestion.

Common Mistakes to Avoid

| Mistake | Consequence | Fix |

|---|---|---|

| Installing proportioning valve on front circuit | Reduced front braking → longer stopping distance | Re-route to rear circuit only |

| Using T-fittings instead of proper distribution | Uneven pressure → brake pull | Use OEM-style blocks or dual-line master |

| Skipping bench bleed | Spongy pedal, hard to bleed | Always bench-bleed before installation |

| Over-tightening flare nuts | Cracked fittings → fluid leaks | Torque to spec: usually 14–20 ft-lbs for 3/16″ lines |

Adjusting Your Proportioning Valve for Optimal Bias

After plumbing, adjustment is key. Here’s a safe method:

- Find an empty, paved lot with consistent surface.

- Drive at 30 mph and apply brakes firmly (not panic stop).

- Observe:

- Rear wheels lock first? → Turn valve clockwise (reduces rear pressure).

- Front wheels lock, rears barely engage? → Turn counterclockwise (increase rear pressure—rarely needed).

- Ideal: All four tires lock simultaneously or front locks just before rear.

Safety Note: Never test on public roads. Use cones and wear seatbelts.

Most adjustable valves require ¼ to 1 full turn from fully open. Mark your starting point with paint!

FAQ Section

Q1: Do I need a proportioning valve if I’m just replacing the master cylinder?

A: Only if you’re changing brake types (e.g., rear drums to discs) or modifying suspension (lowering springs). Stock replacements usually retain the OEM valve.

Q2: Can I use a used proportioning valve?

A: Not recommended. Internal seals degrade over time, leading to pressure leaks or inconsistent modulation. Always use new.

Q3: What’s the difference between a metering valve and a proportioning valve?

A: A metering valve delays front brake application (used with front disc/rear drum systems). A proportioning valve limits rear pressure. Many combo valves include both.

Q4: How do I know if my brake lines are plumbed correctly?

A: Signs of correct plumbing: firm pedal, even pad wear, no pull during braking, and no warning lights (if equipped with brake sensors).

Q5: Can I use copper tubing for brake lines?

A: No. Copper is brittle and illegal for brake lines in all 50 U.S. states. Use steel, stainless steel, or DOT-approved braided lines only.

Q6: How often should I flush brake fluid after this upgrade?

A: Every 2 years or 24,000 miles, whichever comes first. Brake fluid absorbs moisture, lowering its boiling point and risking vapor lock.

Conclusion

Brake line plumbing with a new master cylinder and proportioning valve isn’t just about connecting tubes—it’s about mastering the balance that keeps you safe. Whether you’re restoring a classic, building a track car, or upgrading daily drivers, precision in this process pays off in confidence, control, and stopping power.

Done right, you’ll enjoy a firm pedal, balanced braking, and peace of mind every time you hit the road.

Found this guide helpful? Share it with a fellow gearhead on Facebook, Reddit (r/MechanicAdvice), or Instagram! Your next DIY project might just save someone’s life.

Leave a Reply