If you’re installing or upgrading a propane heating system, getting the plumbing right isn’t just important—it’s critical. An undersized pipe can lead to poor performance, safety hazards, or even system failure during peak demand. This Guide for Sizing the Plumbing for a Propane Heating System walks you through everything you need to know—step by step—to ensure your system runs efficiently, safely, and cost-effectively. Whether you’re a homeowner, contractor, or DIY enthusiast, this guide is designed with clarity, precision, and real-world practicality in mind.

Why Proper Plumbing Sizing Matters for Propane Heating Systems

Many homeowners assume that any gas line will do—but propane behaves differently than natural gas due to its higher energy density and vapor pressure requirements. According to the U.S. Department of Energy, improperly sized gas lines account for nearly 22% of residential heating inefficiencies in off-grid homes.

Undersized pipes cause:

- Pressure drops, leading to incomplete combustion

- Flame instability or burner shutdowns in cold weather

- Increased wear on system components

- Safety risks, including carbon monoxide buildup

Conversely, oversized pipes aren’t inherently dangerous but can be unnecessarily expensive and harder to install. The goal? Just-right sizing based on scientific calculation—not guesswork.

💡 Pro Tip: Always design your system for maximum simultaneous load, not just average usage. Winter nights often demand full capacity from multiple appliances.

How Does Propane Plumbing Differ from Natural Gas?

While both deliver fuel for heating, propane (liquefied petroleum gas or LPG) requires different handling:

| Feature | Propane | Natural Gas |

|---|---|---|

| Pressure at Appliance | 11″ WC (water column) | 7″ WC |

| Energy Content | ~2,500 BTU/ft³ | ~1,000 BTU/ft³ |

| Pipe Sizing | Typically smaller diameter for same BTU load | Larger volume needed |

| Storage | On-site tank (liquid under pressure) | Utility-supplied via mains |

Because propane is stored as a liquid and vaporizes before use, pipe length, elevation changes, and ambient temperature significantly affect delivery pressure—especially in colder climates like Minnesota or Maine.

For authoritative context, see the U.S. Energy Information Administration’s overview of propane.

Step-by-Step: How to Size Your Propane Plumbing System

Follow this industry-standard method used by HVAC professionals and aligned with the National Fuel Gas Code (NFPA 54).

Step 1: Determine Total BTU Load

Add up the input BTU ratings (not output!) of all propane appliances connected to the system:

- Furnace: e.g., 100,000 BTU/hr

- Water heater: 40,000 BTU/hr

- Cooktop: 60,000 BTU/hr

→ Total = 200,000 BTU/hr

⚠️ Never estimate—check the appliance nameplate or manual.

Step 2: Measure Pipe Run Length

Calculate the longest continuous path from the propane tank regulator to the farthest appliance. Include:

- Horizontal distance

- Vertical rise (every 2 ft of elevation ≈ +1 ft equivalent length)

- Fittings (each elbow ≈ +5 ft; tee ≈ +10 ft)

Example:

- Straight run: 60 ft

- 3 elbows: 3 × 5 = 15 ft

- 1 vertical rise (8 ft): ≈ +4 ft

→ Total Equivalent Length = 79 ft

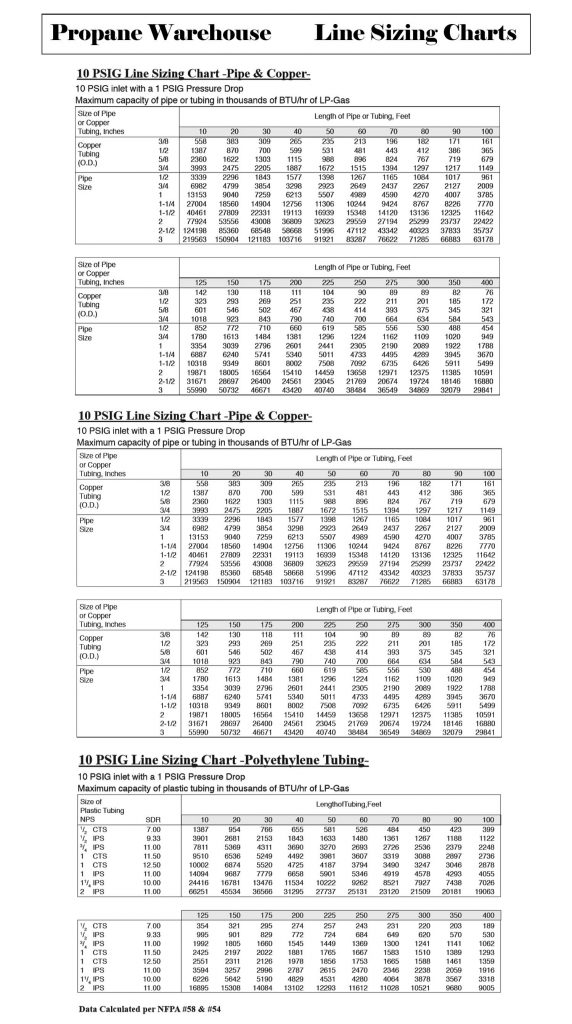

Step 3: Use a Gas Piping Sizing Chart

Refer to standard charts from NFPA 54 or manufacturer guides (e.g., Gastite, Wardflex). Below is a simplified reference for copper or black iron pipe at 11″ WC inlet pressure and max 0.5″ WC pressure drop:

| Pipe Size (Nominal) | Max Capacity (BTU/hr) at 80 ft |

|---|---|

| ½ inch | 125,000 |

| ¾ inch | 275,000 |

| 1 inch | 550,000 |

For our 200,000 BTU load over ~80 ft → ¾-inch pipe is the minimum required.

Step 4: Consider Material & Local Codes

- Black iron pipe: Traditional, durable, but heavy and prone to corrosion if not sealed.

- CSST (Corrugated Stainless Steel Tubing): Flexible, easier to install, but must be properly bonded to prevent lightning damage.

- Copper tubing: Allowed in some jurisdictions for propane (Type K or L), but banned in others—always check local codes.

📌 Real-World Case: In a 2023 inspection by the Maine Fuel Board, 38% of failed propane installations involved incorrect pipe material or undersized lines in new builds.

Common Mistakes to Avoid

Even experienced contractors slip up. Here’s what to watch for:

- Ignoring future expansion – Plan for an extra 20% capacity if adding a garage heater later.

- Using natural gas charts for propane – They’re not interchangeable!

- Skipping pressure testing – Required by code: test at 10 psi for 10+ minutes with no drop.

- Poor support spacing – Pipes must be secured every 4–6 ft to prevent stress leaks.

Tools & Resources You’ll Need

- Digital manometer (to measure water column pressure)

- Pipe thread sealant rated for gas (e.g., RectorSeal #5)

- NFPA 54 codebook or online calculator (many propane suppliers offer free tools)

- Licensed plumber or HVAC technician for final inspection

✅ Best Practice: Have your system inspected by a certified professional—even if DIY is allowed in your area. Safety isn’t worth the risk.

FAQ Section

Q1: Can I use the same pipe size for propane as I did for natural gas?

No. Propane has higher energy content per cubic foot but requires lower flow volume. However, because it’s delivered at higher pressure and is more sensitive to friction loss, pipe sizing must be recalculated specifically for propane using propane-specific charts.

Q2: What happens if my propane line is too small?

You’ll experience low pressure at appliances, causing yellow flames, sooting, frequent shutdowns, or inability to heat during extreme cold. In severe cases, incomplete combustion can produce lethal carbon monoxide.

Q3: Do I need a separate line for each appliance?

Not necessarily. A trunk-and-branch system is common: a main line (e.g., 1″) runs from the tank, then branches (e.g., ¾” or ½”) feed individual appliances. Each branch must be sized for its specific load and distance.

Q4: How cold is too cold for propane plumbing?

Propane vaporizes poorly below −44°F, but in practice, issues start around 0°F if the tank is undersized or the regulator isn’t cold-rated. Use a two-stage regulator and bury lines below the frost line (typically 18–24 inches deep) in northern states.

Q5: Can I size the plumbing myself, or do I need a pro?

You can calculate it yourself using this guide—but installation and pressure testing should be done or verified by a licensed professional. Most jurisdictions require permits and inspections for gas work.

Q6: What’s the maximum allowable pressure drop?

The standard is ≤0.5 inches of water column (WC) from the regulator outlet to the appliance inlet. Exceeding this risks performance and safety.

Conclusion

Getting the plumbing right for your propane heating system isn’t just about comfort—it’s about safety, efficiency, and long-term savings. With this Guide for Sizing the Plumbing for a Propane Heating System, you now have the knowledge to plan intelligently, avoid costly errors, and ensure reliable heat all winter long.

If you found this guide helpful, share it with a friend or neighbor who’s tackling a similar project! And remember: when in doubt, consult a certified HVAC technician or propane supplier. Your family’s warmth—and safety—depend on it.

🔔 Stay warm, stay safe, and never cut corners with gas.

Leave a Reply