If you’re dealing with a clogged or contaminated flammable waste tank plumbing system, you’re not just facing an inconvenience—you’re managing a serious safety hazard. Knowing how do you clean out a flammable waste tank plumbing correctly can prevent fires, explosions, and regulatory violations. Whether you’re a facility manager, plumber, or industrial operator, this guide walks you through the safest, most effective methods—backed by industry standards and expert protocols.

Why Is Cleaning Flammable Waste Tank Plumbing So Critical?

Flammable waste tanks store volatile substances like solvents, oils, or chemical residues. Over time, sludge builds up, pipes corrode, and vapors accumulate—creating conditions ripe for disaster. According to the U.S. Chemical Safety Board (CSB), improper handling of flammable waste contributed to over 30% of industrial fire incidents between 2015–2023.

Cleaning isn’t just about performance—it’s about life safety and legal compliance. The EPA and OSHA require strict procedures for handling hazardous materials, including regular tank maintenance. Ignoring this can result in fines, shutdowns, or worse.

💡 Did You Know? A single spark near unvented flammable vapor can trigger an explosion—even from static electricity during routine cleaning.

What Exactly Is “Flammable Waste Tank Plumbing”?

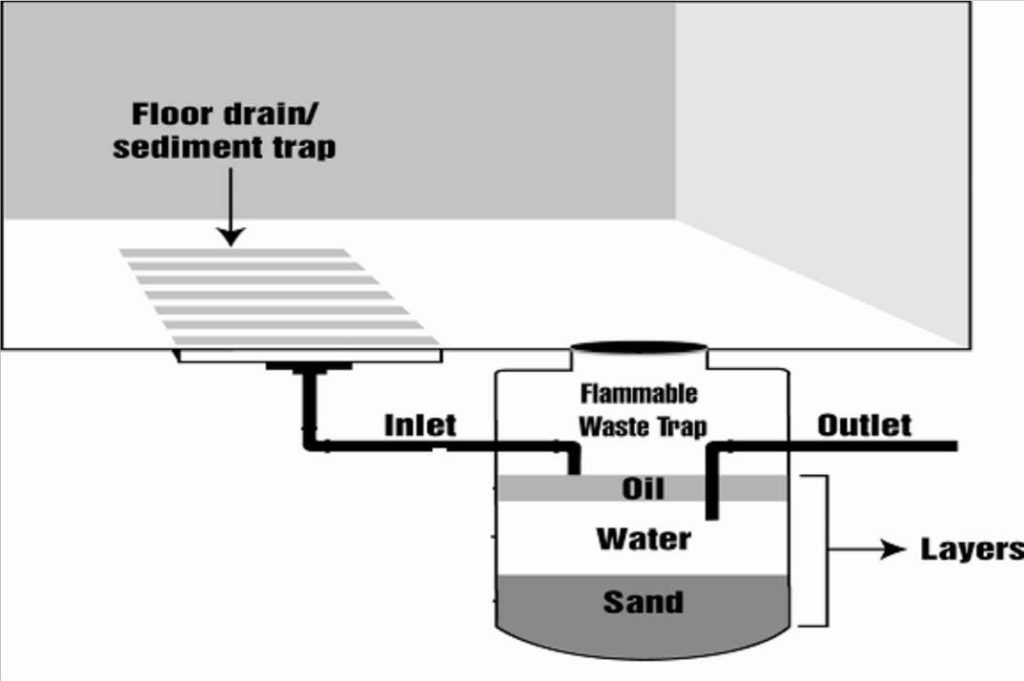

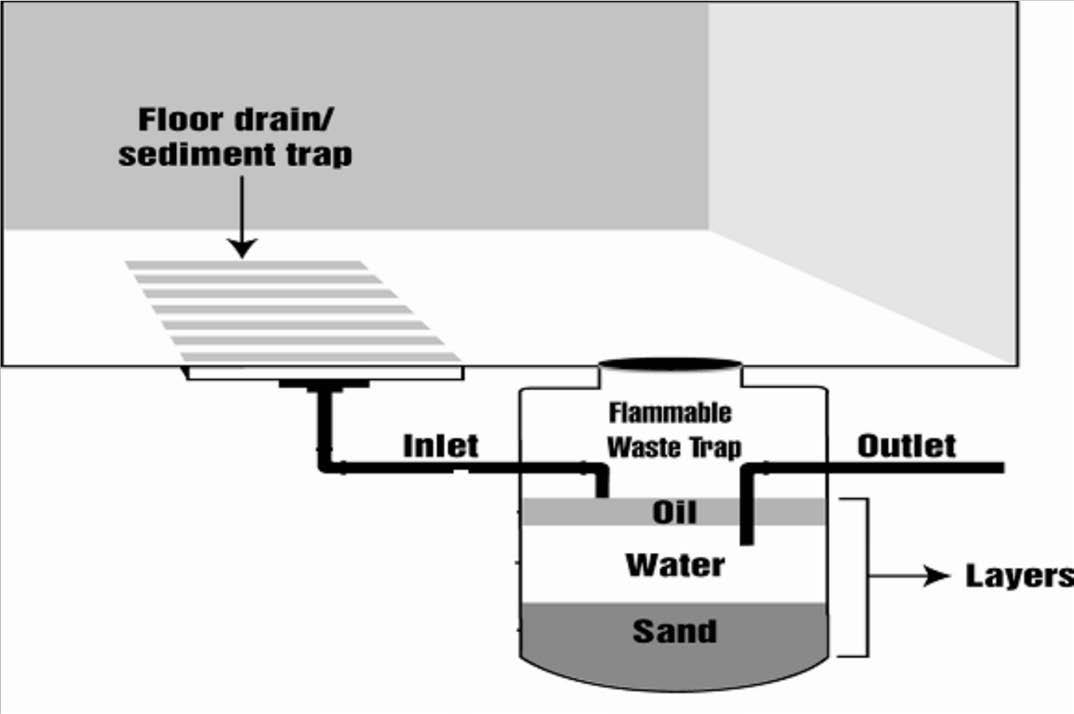

Before diving into the cleaning process, it’s essential to understand the system itself. Flammable waste tank plumbing includes:

- Storage tanks designed for Class I liquids (flash point < 100°F / 37.8°C)

- Piping networks that transport waste to or from the tank

- Vents, pumps, and filters that manage flow and pressure

- Secondary containment systems (e.g., dikes or berms)

These components are often made of stainless steel or specialized polymers to resist corrosion—but even they degrade over time without proper maintenance.

For more on flammable liquid classifications, see the OSHA definition via Wikipedia.

Step-by-Step Guide: How to Safely Clean Flammable Waste Tank Plumbing

⚠️ Warning: Never attempt this without proper training, permits, and PPE. If in doubt, hire a licensed hazardous waste contractor.

Step 1: Shut Down & Isolate the System

- Turn off all pumps, valves, and power sources.

- Lock out/tag out (LOTO) per OSHA 29 CFR 1910.147.

- Close isolation valves upstream and downstream of the tank.

Step 2: Ventilate & Test the Atmosphere

- Use explosion-proof ventilation fans to purge vapors.

- Test air quality with a calibrated gas detector:

- LEL (Lower Explosive Limit) must be <10%

- Oxygen levels between 19.5%–23.5%

- Toxic gases (e.g., benzene, H₂S) below permissible exposure limits (PELs)

🔧 Pro Tip: Allow at least 30–60 minutes of continuous ventilation before entry or cleaning.

Step 3: Drain & Remove Residual Waste

- Pump out remaining liquid into approved DOT-compliant containers.

- Label containers clearly: “Flammable Waste – Do Not Mix.”

- Store temporarily in a ventilated, fire-rated area away from ignition sources.

Step 4: Flush the System

Use a non-sparking, intrinsically safe flushing method:

| Method | When to Use | Volume & Temp |

|---|---|---|

| Water Rinse | For water-miscible solvents (e.g., acetone) | 2–5 gallons per linear foot; 22–28°C (72–82°F) |

| Inert Solvent Flush | For oil-based residues (e.g., toluene) | Use mineral spirits or isopropyl alcohol; follow SDS guidelines |

| Steam Cleaning | Only if system is rated for high-temp service | Max 100°C (212°F); avoid open flames |

Never use compressed air—it can generate static sparks.

Step 5: Mechanical Cleaning (If Needed)

For stubborn sludge or scale:

- Use explosion-proof rotary cleaners or pigging systems.

- Avoid metal brushes that could cause sparks—opt for nylon or Teflon tools.

- Collect all debris in sealed, grounded containers.

Step 6: Inspect & Document

- Check for corrosion, cracks, or leaks using borescopes or ultrasonic testing.

- Record findings in your facility’s maintenance log.

- Retain records for at least 3 years (per EPA RCRA requirements).

Common Mistakes to Avoid

Many accidents happen due to simple oversights. Here’s what not to do:

- ❌ Skipping atmospheric testing – “It smells fine” isn’t enough.

- ❌ Using household cleaners – Many contain oxidizers that react dangerously with solvents.

- ❌ Draining waste into floor drains – Illegal under EPA regulations unless pre-approved.

- ❌ Working alone – Always have a trained observer outside the work zone.

📊 Case Study: In 2021, a Texas auto shop exploded during tank cleaning because workers used a standard garden hose near residual gasoline vapors. The CSB cited “inadequate hazard assessment” as the root cause.

Tools & PPE You’ll Need

Safety starts with the right gear. Ensure you have:

- Explosion-proof lighting and tools

- Chemical-resistant suit (Tyvek® with anti-static coating)

- Self-contained breathing apparatus (SCBA) or supplied-air respirator

- Grounding clamps to prevent static discharge

- Fire extinguisher (Class B) rated for flammable liquids

All equipment must meet NFPA 30 and OSHA 1910.120 standards.

When to Call a Professional

While small systems may be cleaned in-house, hire a licensed hazardous waste contractor if:

- The tank holds >55 gallons of flammable material

- You lack atmospheric monitoring equipment

- Your staff isn’t HAZWOPER-certified (minimum 24-hour training)

- Local regulations require third-party oversight (common in CA, NY, TX)

Professionals use advanced methods like vacuum truck extraction or closed-loop cleaning systems that minimize exposure.

FAQ Section

Q1: Can I use a pressure washer to clean flammable waste lines?

A: No. Standard pressure washers create sparks and aerosolize flammable vapors—extremely dangerous. Only use intrinsically safe, certified equipment designed for hazardous environments.

Q2: How often should I clean my flammable waste tank plumbing?

A: It depends on usage, but OSHA and NFPA recommend annual inspections and cleaning whenever sludge exceeds 1 inch in depth or flow is restricted by >15%.

Q3: Is it legal to dump flammable waste down the drain after dilution?

A: Absolutely not. Even diluted, flammable waste is regulated under the Resource Conservation and Recovery Act (RCRA). Improper disposal can lead to fines up to $76,764 per violation (EPA, 2025).

Q4: What’s the difference between cleaning and decontaminating?

A: Cleaning removes visible residue; decontamination ensures no hazardous vapors or residues remain—required before repair, decommissioning, or resale. Decon often involves multiple solvent rinses and vapor testing.

Q5: Can I reuse the flushed solvent?

A: Only if it meets purity specs and is handled per your facility’s waste minimization plan. Most facilities treat flushed solvents as new hazardous waste and dispose of them properly.

Q6: Do I need a permit to clean the tank myself?

A: Possibly. Check with your state environmental agency. In California, for example, even minor tank cleaning may require a Tiered Permit under Cal/EPA Title 22.

Conclusion

Knowing how do you clean out a flammable waste tank plumbing isn’t just technical know-how—it’s a critical safety responsibility. By following these evidence-based steps, you protect your team, your facility, and the environment while staying compliant with federal and state laws.

Don’t gamble with shortcuts. When in doubt, consult a certified hazardous materials specialist. And if this guide helped you, share it with a colleague—safety multiplies when knowledge spreads.

🔔 Stay safe. Stay compliant. Keep cleaning smart.

Leave a Reply