If you’ve recently moved into an older home or are upgrading your plumbing system, you might be wondering: how do you go from PEX to conventional plumbing fittings? PEX (cross-linked polyethylene) is popular for its flexibility and ease of installation—but what if your existing system uses copper, galvanized steel, or CPVC? Transitioning between these systems isn’t just possible—it’s common. And with the right tools and knowledge, you can do it safely and code-compliantly. In this guide, we’ll walk you through every step, so you avoid leaks, pressure issues, and costly mistakes.

Why Would You Need to Convert From PEX to Conventional Fittings?

Homeowners often face this dilemma during renovations, repairs, or when integrating new fixtures into legacy plumbing systems. According to the U.S. Department of Energy, over 60% of homes built before 2000 used copper or galvanized steel pipes—materials that don’t directly connect to PEX without adapters.

Common scenarios include:

- Replacing a section of old copper pipe with PEX but needing to reconnect to existing valves or fixtures.

- Installing a new water heater that requires threaded connections.

- Upgrading a bathroom where the shower valve only accepts sweat-soldered copper.

The key is using the right transition fittings—and knowing which ones comply with local plumbing codes.

What Are Conventional Plumbing Fittings?

“Conventional” typically refers to metal-based systems like:

- Copper (Type M, L, or K)

- Galvanized steel (now largely outdated due to corrosion)

- Brass compression or threaded fittings

- CPVC (chlorinated polyvinyl chloride), though technically plastic, it’s often grouped with “traditional” rigid piping

Unlike PEX—which uses crimp, clamp, or push-fit connections—conventional systems rely on soldering, threading, or solvent welding.

💡 Pro Tip: Always check your local building code. The International Plumbing Code (IPC) allows PEX-to-copper transitions, but some municipalities restrict certain adapter types.

For more on plumbing materials’ history and standards, see Wikipedia’s overview of plumbing systems.

Step-by-Step: How to Transition From PEX to Conventional Fittings

Follow these steps carefully. Mistakes here can lead to leaks, reduced water pressure, or even pipe bursts.

Step 1: Turn Off Water & Relieve Pressure

- Shut off the main water supply.

- Open the lowest faucet in your home to drain residual water.

- Use a bucket and towels—expect some drips.

Step 2: Cut the PEX Tubing Cleanly

- Use a PEX tubing cutter (not regular scissors!) to make a straight, burr-free cut.

- Ensure the end is smooth—rough edges compromise seal integrity.

Step 3: Choose the Right Adapter

This is the most critical decision. Common adapter types:

| Adapter Type | Best For | Installation Method |

|---|---|---|

| Brass PEX-to-Copper Sweat Adapter | Connecting to soldered copper lines | Solder one end, insert PEX on the other |

| Threaded PEX-to-FIP/MIP Adapter | Connecting to shower valves, water heaters | Screw onto male/female threads |

| Compression Adapter | Temporary fixes or non-solder zones | Hand-tighten + wrench (no heat needed) |

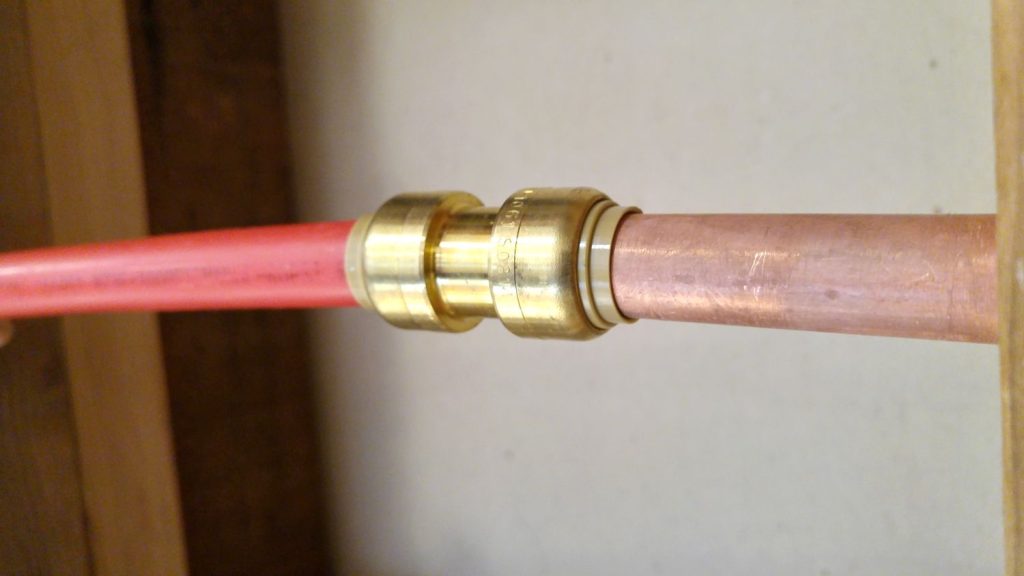

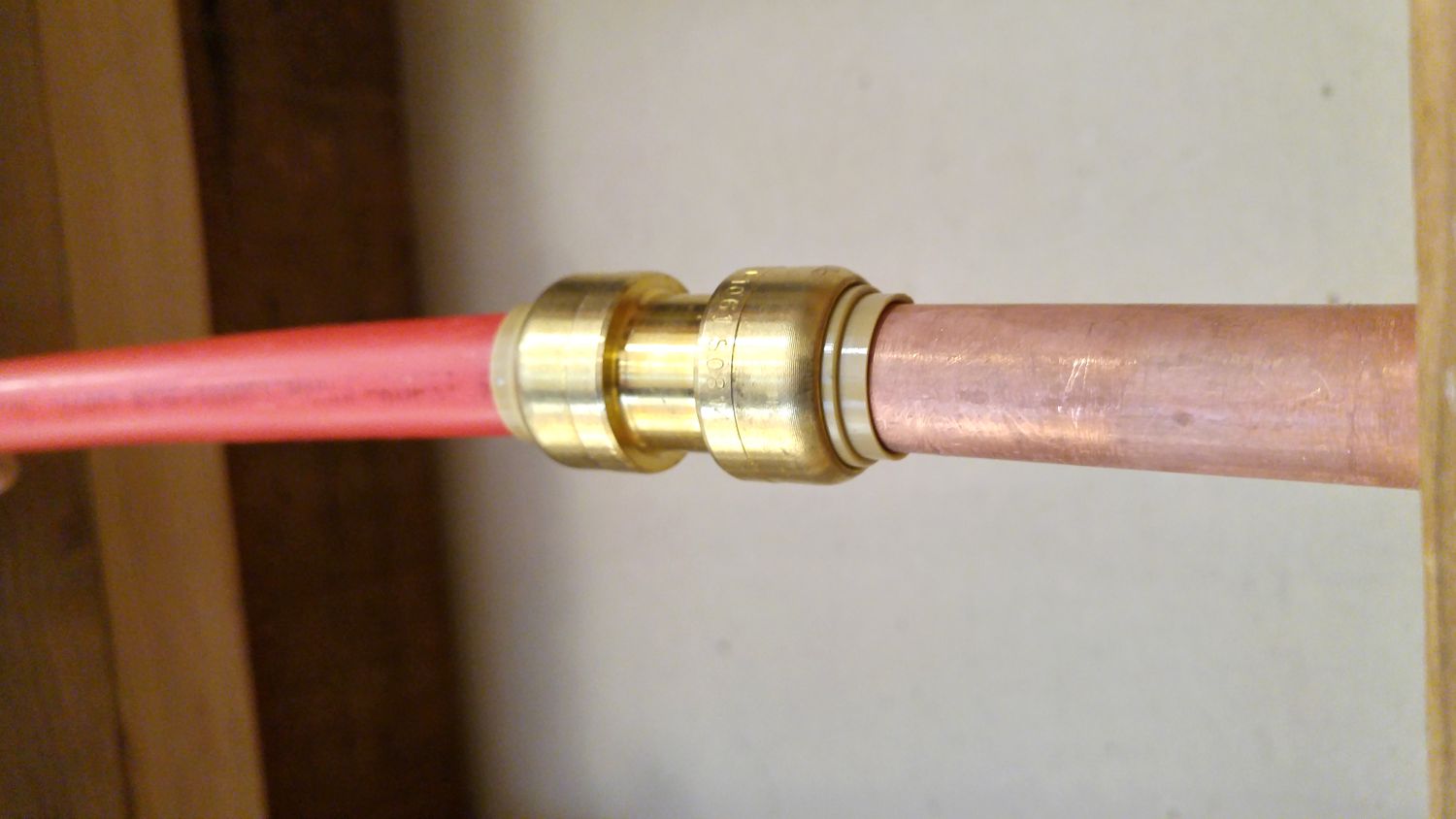

| Push-Fit Transition Coupling | Quick DIY jobs (e.g., SharkBite) | Push PEX in one side, copper in the other |

⚠️ Warning: Avoid cheap zinc or die-cast adapters—they corrode quickly. Stick with lead-free brass certified to NSF/ANSI 61.

Step 4: Install the Adapter

- For sweat adapters: Clean copper pipe with emery cloth, apply flux, solder at 700°F (371°C). Let cool completely before connecting PEX.

- For push-fit: Insert PEX fully until it clicks (you should hear a slight snap). Pull back gently to confirm it’s locked.

- For threaded: Wrap Teflon tape (3–5 wraps clockwise) on male threads before tightening.

Step 5: Pressure Test the Connection

- Turn water back on slowly.

- Check for leaks at the joint for at least 10 minutes under full household pressure (typically 40–80 PSI).

- If leaking, disassemble and recheck insertion depth or solder quality.

PEX-to-Conventional: Pros and Cons

| Factor | PEX Advantage | Conventional Advantage |

|---|---|---|

| Installation Speed | ✅ Faster (no soldering) | ❌ Slower (requires skill/tools) |

| Durability | ❌ Vulnerable to UV/sunlight | ✅ Copper lasts 50+ years |

| Cost | ✅ Lower material cost | ❌ Higher labor & material cost |

| Freeze Resistance | ✅ Expands without bursting | ❌ Prone to cracking |

| Compatibility | ❌ Needs adapters | ✅ Direct fixture compatibility |

While PEX dominates new construction (accounting for over 70% of residential repiping per PHCC), legacy systems still demand hybrid solutions.

Common Mistakes to Avoid

- Using non-barrier PEX with hydronic heating – Oxygen can corrode metal components. Use oxygen-barrier PEX (red/blue stripe) if connecting to boilers or radiators.

- Over-tightening compression fittings – This cracks the ferrule. Hand-tight plus 1/2 turn with a wrench is enough.

- Ignoring expansion loops – PEX expands/contracts with temperature. Leave slight slack near rigid connections.

- Mixing incompatible metals – Direct contact between copper and galvanized steel causes galvanic corrosion. Always use a dielectric union.

FAQ Section

Q1: Can I connect PEX directly to a copper pipe without an adapter?

A: No. PEX cannot be soldered or threaded. You must use a mechanical adapter (sweat, push-fit, or compression) rated for both materials.

Q2: Are SharkBite fittings reliable for permanent PEX-to-copper transitions?

A: Yes—when installed correctly. SharkBite and similar push-fit fittings are IAPMO-listed and approved for behind-wall use in most U.S. jurisdictions. Just ensure the pipe is clean, deburred, and fully inserted.

Q3: Do I need a permit to convert PEX to conventional fittings?

A: It depends on your location and scope. Minor repairs usually don’t require permits, but full repiping or water heater connections often do. Check with your local building department.

Q4: What’s the lifespan of a PEX-to-copper adapter?

A: High-quality brass adapters last 20–50 years—similar to copper itself—provided they’re not exposed to excessive vibration or improper installation.

Q5: Can I use PEX adapters with galvanized steel pipes?

A: Technically yes, but not recommended. Galvanized pipes often have internal rust and reduced diameter. Replace the galvanized section with copper or PEX first, then transition.

Q6: Is there a difference between PEX-A, PEX-B, and PEX-C for fittings?

A: Yes. PEX-A (made via Engel method) is more flexible and works with expansion-style fittings. PEX-B/C typically use crimp or clamp rings. Always match the fitting type to your PEX brand.

Conclusion

Knowing how do you go from PEX to conventional plumbing fittings empowers you to modernize your plumbing without ripping out your entire system. Whether you’re a weekend DIYer or a seasoned contractor, using the right adapters, following code guidelines, and pressure-testing your work ensures a leak-free, long-lasting connection.

Don’t let incompatible pipes stop your renovation! With this guide, you’ve got the confidence—and the technical know-how—to bridge old and new plumbing worlds seamlessly.

👉 Found this helpful? Share it with a friend tackling a home upgrade! #PlumbingTips #DIYHome #PEXConversion

Leave a Reply