Building or maintaining a race car isn’t just about horsepower—it’s about precision. One of the most overlooked yet critical components is the fuel delivery system, and specifically, how much fuel line needed to plumb a race car correctly. Too little, and you risk kinks or leaks; too much, and you add unnecessary weight or complexity. Whether you’re a weekend racer or a pro builder, getting this right ensures safety, performance, and compliance with racing regulations. Let’s break it down step by step.

Why Accurate Fuel Line Length Matters in Racing

In high-performance environments, every inch counts—not just for aerodynamics, but for fluid dynamics too. An improperly sized fuel line can lead to:

- Fuel starvation under hard cornering or acceleration

- Excessive pressure drop due to overly long or narrow lines

- Increased fire risk from poorly routed or unsupported hoses

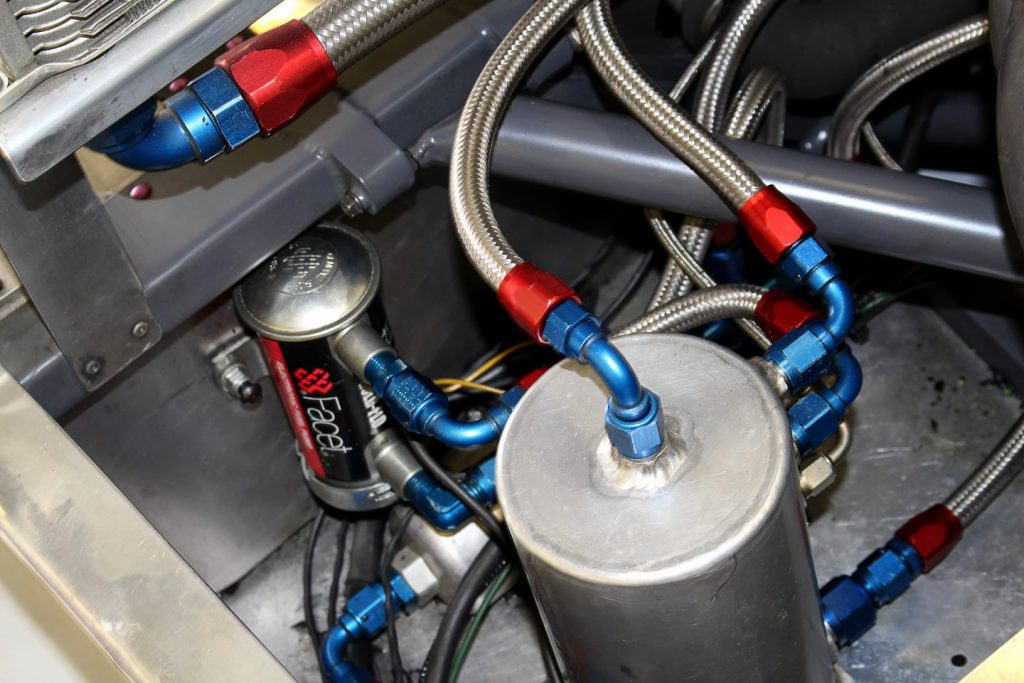

According to the Sports Car Club of America (SCCA) Rulebook, all fuel lines must be securely fastened, protected from chafing, and use materials rated for high-pressure fuel systems—typically PTFE (Teflon) or reinforced braided stainless steel.

“A well-plumbed fuel system isn’t just about flow—it’s about reliability under extreme conditions,” says Mike Johnson, lead engineer at Radium Engineering, a leader in motorsport fuel systems.

How to Calculate the Exact Fuel Line Length You Need

There’s no universal number—but there is a reliable method. Here’s how professionals do it:

Step 1: Map Your Fuel System Layout

Start by identifying all key components:

- Fuel tank (or cell)

- Fuel pump(s)

- Fuel filter(s)

- Regulator(s)

- Fuel rail(s) or carburetor(s)

- Return line (if applicable)

Sketch a simple diagram or use your chassis as a reference.

Step 2: Measure Point-to-Point Distances

Use a flexible measuring tape or string to trace the actual path the line will take—including bends, brackets, and firewall penetrations. Never measure in a straight line!

Pro Tip: Add 10–15% extra length to accommodate:

- Engine movement (especially in solid-mounted race engines)

- Future adjustments or component swaps

- Proper bend radii (sharp bends restrict flow)

Step 3: Account for Fittings and Connectors

Each AN fitting, adapter, or swivel adds 1–2 inches of effective length. Don’t forget these!

Real-World Example:

A typical NASA-spec Miata race car with a rear-mounted fuel cell and front-mounted engine might need:

- Feed line: ~12–14 feet

- Return line: ~10–12 feet

- Vent/purge lines: 3–5 feet (if used)

Total: 25–31 feet of high-pressure fuel line.

Common Fuel Line Types & Their Impact on Length Needs

Not all fuel lines are created equal. Your choice affects both routing flexibility and required length.

| Material | Max Operating Pressure | Flexibility | Typical Use Case |

|---|---|---|---|

| Braided Stainless Steel (AN) | 1,000+ PSI | Moderate | High-pressure EFI systems |

| PTFE (Teflon) with Braid | 1,500+ PSI | High | Professional motorsport, E85/methanol |

| Nylon/Polyamide | 300–500 PSI | Very High | Low-budget builds, non-boosted apps |

| Rubber Hose (SAE) | <250 PSI | High | Not recommended for race cars |

⚠️ Never use standard rubber fuel hose in a race car. It degrades quickly under heat, ethanol, and vibration—and fails catastrophically. The National Fire Protection Association (NFPA) explicitly discourages its use in competition vehicles.

For more on material standards, see Wikipedia’s entry on automotive fuel lines.

People Also Ask: Answering Top User Questions

❓ Does fuel line diameter affect how much I need?

Diameter doesn’t change the length required, but it does affect flow capacity. Most race cars use -6 AN (3/8″) for feed lines and -4 AN (1/4″) for return lines. Oversizing won’t hurt flow—but undersizing can cause fuel starvation at high RPM.

❓ Can I reuse old fuel lines?

Only if they’re PTFE or stainless steel and show no signs of wear, kinking, or corrosion. Rubber or nylon lines should be replaced annually in race applications.

❓ What’s the minimum bend radius for AN lines?

For -6 AN, maintain at least a 3-inch bend radius. Tighter bends crimp the inner liner and reduce flow by up to 40%.

Step-by-Step: Plumbing Your Race Car Fuel System

Follow this checklist to ensure a safe, efficient install:

- Drain and purge the old fuel system completely.

- Dry-fit all components using temporary tubing or string.

- Cut lines to length with a rotary cutter (not a hacksaw—burrs cause turbulence).

- Install fittings hand-tight, then torque to spec (e.g., 25–30 ft-lbs for -6 AN).

- Secure every 6–8 inches with aluminum or stainless clamps—never zip ties.

- Pressure-test the system with air or inert gas before adding fuel.

- Inspect for leaks at 1.5x operating pressure (e.g., 90 PSI for a 60 PSI system).

🔧 Tool Tip: Use a bubble leak detector spray (like Snoop®) on all joints during testing.

FAQ Section

Q1: How much fuel line do I need for a drag car vs. a road racer?

Drag cars often have shorter runs (tank near engine), needing 15–20 feet total. Road racers with rear fuel cells typically require 25–35 feet due to longer chassis and complex routing.

Q2: Should I include extra length for a dry-sump oil system?

No—oil and fuel systems are separate. But if your dry-sump tank shares space with the fuel cell, plan routing to avoid interference.

Q3: Can I coil excess fuel line to “store” extra length?

Never coil high-pressure fuel lines. Coils trap heat, promote vapor lock, and create turbulence. Instead, use gentle S-bends or secure loops with proper supports.

Q4: What’s the biggest mistake beginners make?

Using insufficient support clamps. Unsecured lines vibrate, fatigue, and eventually fail. Clamp every 6–8 inches, especially near the engine.

Q5: Do electric fuel pumps need different line lengths than mechanical ones?

Pump type doesn’t change length—but electric pumps often sit farther from the tank, increasing feed-line distance. Always place the pump as close to the tank as possible for better priming.

Q6: Is there a formula to estimate fuel line length?

Rough estimate:

Total Length (ft) = (Wheelbase in inches ÷ 12) × 2.2 + 5

Example: 95″ wheelbase → (95 ÷ 12) × 2.2 + 5 ≈ 22.4 feet

Use this only for initial ordering—always verify with physical measurement.

Conclusion

Knowing how much fuel line needed to plumb a race car isn’t guesswork—it’s engineering. By mapping your layout, choosing the right materials, and allowing for real-world variables like engine movement and safety margins, you’ll build a system that’s both fast and fail-safe.

Whether you’re prepping for your first track day or fine-tuning a championship contender, precision in your fuel plumbing pays off in laps, not just longevity.

Found this guide helpful? Share it with your crew or post it in your racing forum!

🔧 Safe racing starts with smart plumbing.

Leave a Reply