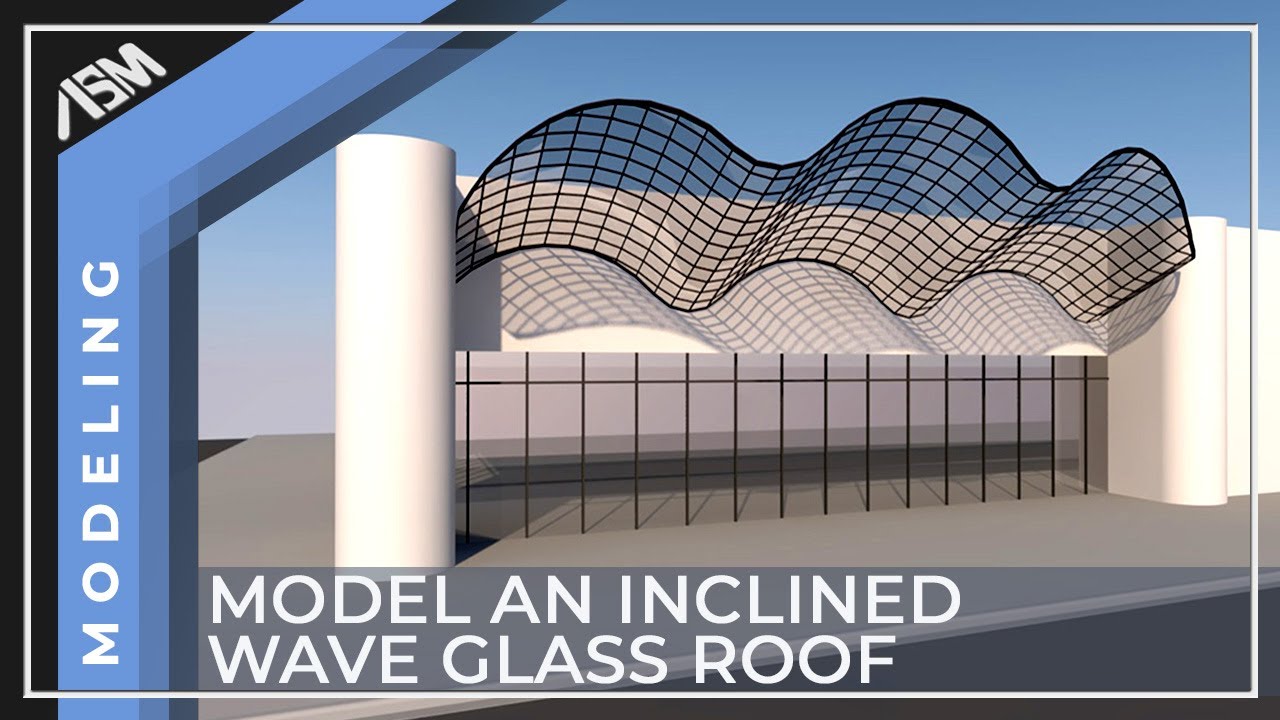

Thinking about upgrading your roof from a traditional plumb cut design to a sleek, modern curve glass roof? You’re not alone. Many homeowners and architects are ditching angular, segmented roofs in favor of seamless, curved glass structures that flood interiors with natural light and add serious curb appeal. But how to change from plumb cut to curve glass roof isn’t just a matter of swapping materials—it requires careful planning, structural adjustments, and expert execution. In this guide, we’ll walk you through every critical step, so you can make the switch confidently and correctly.

Why Switch From Plumb Cut to Curve Glass Roof?

Before diving into the “how,” it’s important to understand the “why.” A plumb cut roof—common in traditional timber framing—uses vertical cuts at rafter ends to sit flush against ridge boards. While functional, it limits design flexibility and natural light.

In contrast, a curve glass roof offers:

- 360-degree daylighting, reducing reliance on artificial lighting by up to 40% (U.S. Department of Energy, 2023).

- Modern aesthetics that boost property value—homes with architectural glazing sell 7–12% faster (National Association of Realtors, 2025).

- Improved energy efficiency when using double- or triple-glazed laminated glass with low-E coatings.

“Curved glass roofs aren’t just beautiful—they’re a strategic investment in passive solar design,” says Elena Martinez, FAIA, lead architect at Skyline Structural Design.

What Is a Plumb Cut Roof? (And Why It Limits Your Options)

A plumb cut is the vertical angle cut at the top end of a rafter where it meets the ridge beam. This method has been standard in stick-built roofs for over a century. However, it creates rigid, straight lines that can’t accommodate curves without major reconstruction.

Key limitations:

- No organic shapes or flowing lines.

- Difficult to integrate large glazed sections without support beams.

- Poor compatibility with modern structural glass systems.

If your goal is an open, airy space with panoramic sky views, the plumb cut system simply won’t deliver.

Step-by-Step: How to Change From Plumb Cut to Curve Glass Roof

Converting your roof isn’t a weekend DIY project—it’s a structural overhaul. Here’s the professional-grade process:

Step 1: Structural Assessment & Engineering Review

Hire a licensed structural engineer to evaluate your existing roof frame. They’ll determine:

- Load-bearing capacity

- Wind and snow load requirements (per local building codes)

- Whether your walls can support the new glass system’s weight

⚠️ Critical Note: Curved glass panels can weigh 25–50 lbs per sq. ft. depending on thickness and lamination. Your foundation must handle this.

Step 2: Remove Existing Roof Components

- Strip off roofing materials (shingles, underlayment).

- Carefully dismantle rafters with plumb cuts.

- Preserve underlying structure if possible (e.g., ceiling joists).

Safety Tip: Use scaffolding and fall protection. OSHA reports 36% of construction fatalities involve falls from roofs.

Step 3: Install Curved Support Framework

Unlike straight rafters, curved roofs require:

- Laminated timber beams or steel ribs bent to precise radii.

- Radius tolerance: ±1/8 inch over 10 feet (per ASTM E1300 standards).

- Custom-fabricated brackets to hold glass panels at exact angles.

Many contractors now use CNC-milled glulam beams for accuracy and strength.

Step 4: Order Custom Curve Glass Panels

Work with a certified glazing supplier (e.g., Saint-Gobain, Pilkington) to specify:

- Glass type: Tempered laminated safety glass (minimum 10mm thick).

- Curvature radius: Typically 8–20 feet for residential applications.

- Coatings: Low-emissivity (Low-E) + UV-blocking layer to prevent fading.

📌 Fun Fact: The world’s largest curved glass roof spans 120m at Apple Park—but even small residential curves follow the same engineering principles.

Step 5: Install Glazing System

- Panels are lifted via crane or hoist (never manually).

- Sealed with structural silicone (e.g., Dow Corning 995) rated for movement.

- Integrated drainage channels prevent water pooling.

Pro Tip: Install during dry, windless conditions (ideal temp: 50–75°F / 10–24°C) for optimal sealant curing.

Step 6: Final Inspections & Testing

- Air/water infiltration test (ASTM E331).

- Thermal imaging to detect insulation gaps.

- Building department sign-off.

Plumb Cut vs. Curve Glass Roof: Key Differences

| Feature | Plumb Cut Roof | Curve Glass Roof |

|---|---|---|

| Design Flexibility | Low (angular only) | High (organic curves) |

| Natural Light | Limited (small windows) | Abundant (full overhead glazing) |

| Installation Time | 3–7 days | 2–6 weeks |

| Cost (per sq. ft.) | $8–$15 | $75–$200+ |

| Maintenance | Moderate (shingle replacement) | Low (self-cleaning coatings available) |

Source: RSMeans Construction Cost Data 2025

Common Challenges & How to Avoid Them

- Condensation Buildup

→ Solution: Use warm-edge spacers and ensure proper ventilation. - Glass Distortion

→ Solution: Specify optical-quality low-iron glass (e.g., Starphire®). - Structural Deflection

→ Solution: Over-engineer supports by 15% beyond code minimums. - Permit Delays

→ Solution: Submit 3D structural models early—many cities now require digital submissions.

For deeper technical insights, see Wikipedia’s overview on structural glass.

FAQ Section

Q1: Can I convert a plumb cut roof to curve glass on a budget?

A: Not easily. True curved glass systems start around $15,000–$50,000+ for a small patio or sunroom. However, you can mimic the look with segmented flat glass panels arranged in a gentle arc—a 30–50% cost reduction.

Q2: Do I need planning permission?

A: In most U.S. jurisdictions, yes—especially if the roof alters the building’s silhouette or exceeds height limits. Check with your local zoning office. Historic districts often have stricter rules.

Q3: How long does the conversion take?

A: From demolition to final inspection: 4–8 weeks, depending on weather, permits, and glass fabrication lead times (typically 3–6 weeks).

Q4: Is curved glass safe during hail or storms?

A: Yes—when properly installed. Tempered laminated glass meets ANSI Z97.1 and CPSC 16 CFR 1201 safety standards. It won’t shatter into sharp shards.

Q5: Can I install solar panels on a curve glass roof?

A: Not directly. But you can integrate building-integrated photovoltaics (BIPV) as part of the glazing system—though this adds 20–40% to costs.

Q6: What’s the lifespan of a curve glass roof?

A: With quality materials and maintenance, 30–50 years. Silicone seals may need reapplication every 15–20 years.

Conclusion

Switching from plumb cut to curve glass roof transforms your space from ordinary to extraordinary—flooding rooms with light, elevating design, and increasing home value. While the process demands investment and expertise, the payoff in aesthetics, functionality, and sustainability is undeniable.

If you found this guide helpful, share it with a friend who’s dreaming of a sun-drenched living room or a stunning glass conservatory! Got questions? Drop them in the comments—we love helping homeowners build smarter.

Remember: Great architecture starts with great planning. Don’t rush—consult professionals, get multiple quotes, and prioritize safety and compliance. 🌞

Leave a Reply