If you’ve ever wrestled with clunky, hard-to-reach hose clamps under your boat’s cramped galley sink—or worse, dealt with a slow drip that turned into a soggy mess—you’re not alone. Many boat owners struggle with outdated plumbing systems that are time-consuming to maintain and prone to leaks. How to convert boat plumbing to 15mm quick connect is a practical solution that offers faster repairs, easier winterization, and a more reliable freshwater system. In this guide, we’ll walk you through the entire process—step by step—with expert tips, real-world insights, and everything you need to do it right the first time.

Why Upgrade to 15mm Quick Connect Fittings?

Before diving into the “how,” let’s clarify the “why.” Traditional marine plumbing often uses barbed fittings secured with stainless steel hose clamps. While functional, they require tools, time, and precision to install or remove—especially in tight spaces.

15mm quick connect fittings, on the other hand, allow you to:

- Disconnect and reconnect hoses in seconds—no tools needed

- Reduce the risk of leaks during reassembly

- Simplify winterizing or servicing your freshwater system

- Improve overall system reliability

According to a 2023 survey by BoatUS, over 68% of boat owners who upgraded to quick-connect plumbing reported fewer leaks and faster maintenance turnaround.

💡 Pro Tip: The “15mm” refers to the outer diameter (OD) of the tubing commonly used in European and many modern marine freshwater systems. In the U.S., this is often equivalent to 5/8″ OD tubing—but always measure yours before buying fittings.

What Tools and Materials Do You Need?

Converting your system doesn’t require a full replumb—just strategic upgrades at key junctions. Here’s your shopping list:

| Item | Purpose |

|---|---|

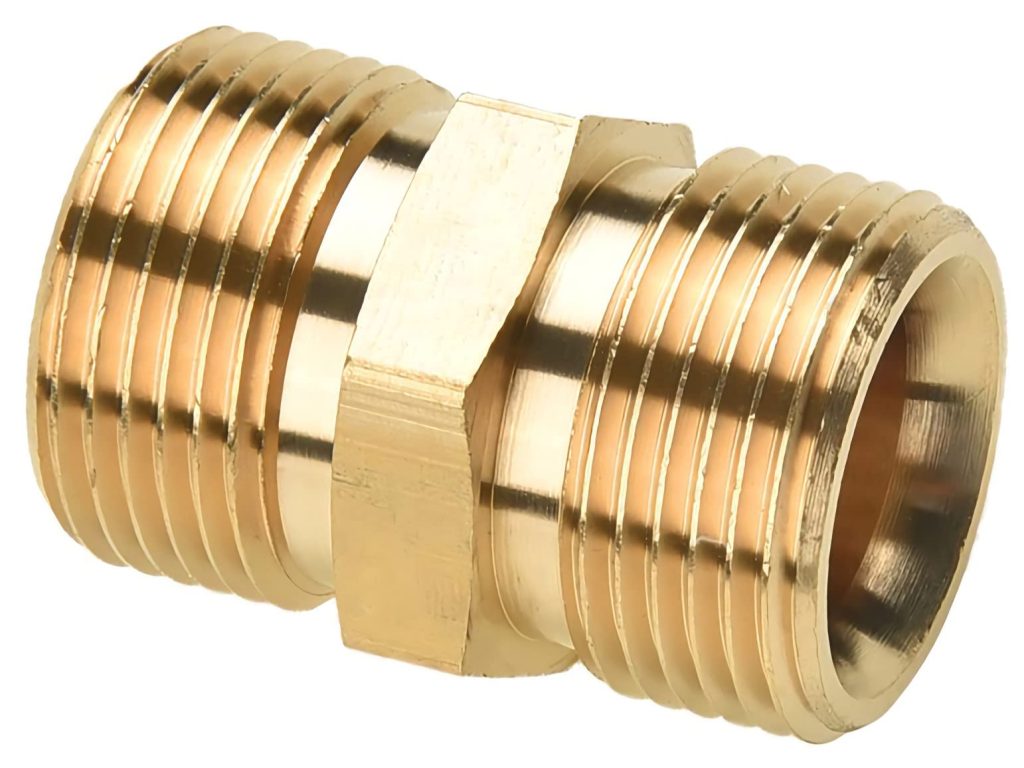

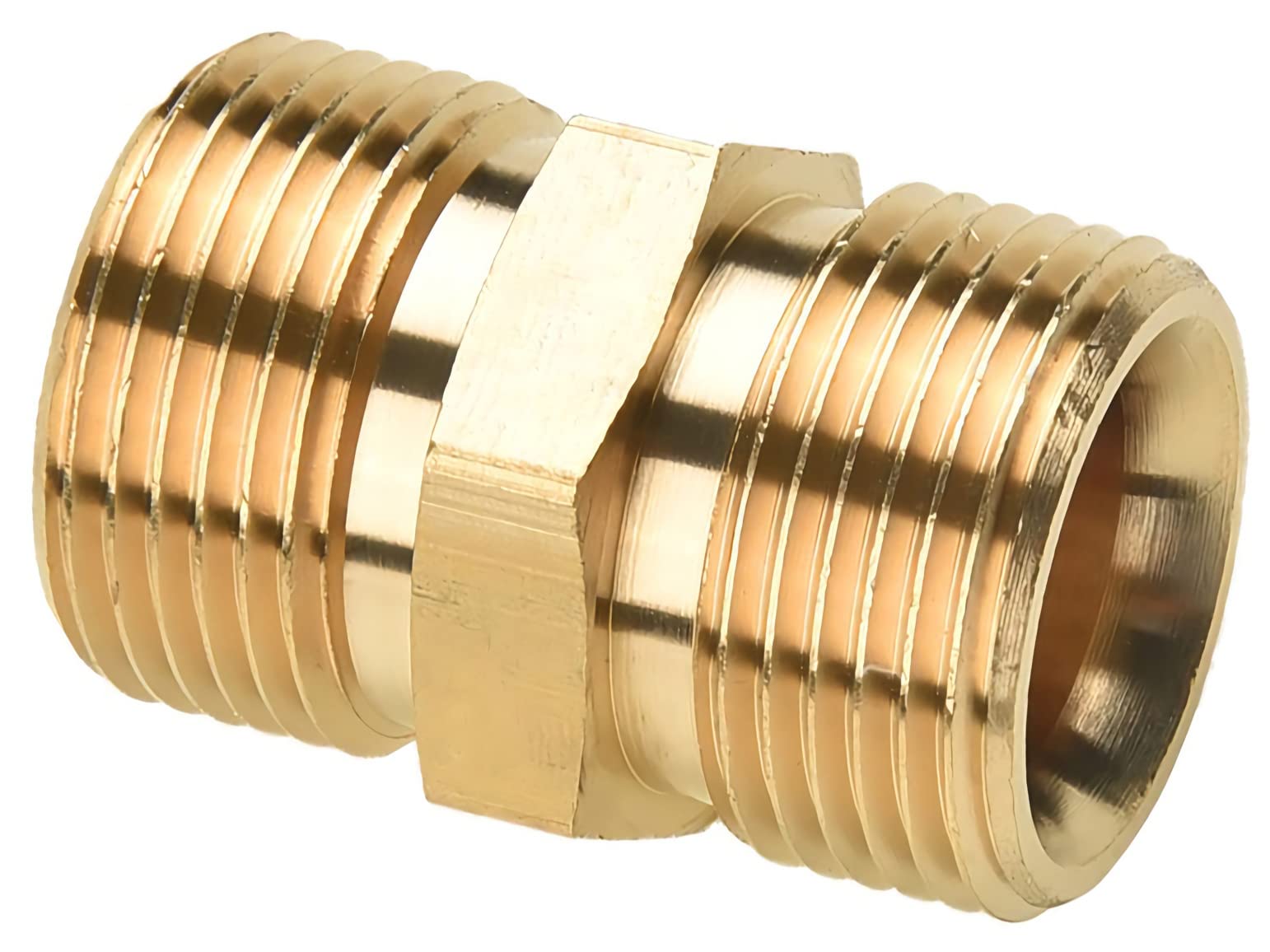

| 15mm quick connect fittings (male & female) | Core components for tool-free connections |

| Marine-grade PEX or reinforced vinyl tubing (15mm OD) | Flexible, durable, and compatible with potable water |

| Hose cutter or sharp utility knife | Clean, square cuts prevent leaks |

| Deburring tool or fine sandpaper | Smooth tube ends for proper seal |

| Teflon tape or thread sealant (if adapting to threaded ports) | Ensures watertight threaded connections |

| Adjustable wrench or pliers | For removing old clamps/fittings |

⚠️ Important: Always use marine-certified fittings rated for potable water. Look for NSF/ANSI 61 or ISO 14001 certification. Avoid generic hardware-store versions—they may degrade or leach chemicals into your drinking water.

For more on material safety standards, see Wikipedia’s overview on potable water regulations.

Step-by-Step Guide: Converting Your Boat Plumbing

Follow these steps carefully. Even if you’re new to DIY boat work, this project is beginner-friendly with the right prep.

Step 1: Turn Off Water Supply & Drain the System

- Shut off the freshwater pump.

- Open all faucets to relieve pressure and drain residual water.

- Place towels or a bucket under work areas—expect minor drips.

Step 2: Identify Conversion Points

Focus on high-maintenance or frequently accessed sections:

- Under-sink connections (galley, head)

- Water heater inlet/outlet

- Pump outlet or accumulator tank

- Filter housings

Avoid converting every joint—only where quick access adds value.

Step 3: Remove Old Fittings

- Loosen hose clamps with a screwdriver or socket wrench.

- Gently twist and pull hoses off barbed fittings.

- If stuck, apply gentle heat with a hair dryer to soften the tubing.

Step 4: Prepare New Tubing

- Measure and cut new 15mm tubing to length (add 1–2 inches for error).

- Use a hose cutter for a clean, perpendicular cut.

- Deburr the inside and outside edges to prevent O-ring damage.

Step 5: Install Quick Connect Fittings

- Push tubing fully into the fitting until you hear a click—this means the internal collet has engaged.

- Give a gentle tug to confirm it’s locked.

- For threaded adapters (e.g., connecting to a pump), wrap threads with Teflon tape and hand-tighten, then give a quarter-turn with a wrench.

🔧 Real-World Example: A sailor in Florida converted his Catalina 30’s galley plumbing in under 45 minutes using SharkBite 15mm push-fit connectors. He reported zero leaks after six months of coastal cruising.

Quick Connect vs. Traditional Fittings: Pros & Cons

| Feature | 15mm Quick Connect | Traditional Barbed + Clamp |

|---|---|---|

| Installation Speed | Seconds | Minutes (tools required) |

| Leak Risk | Low (if installed correctly) | Moderate (clamp tension critical) |

| Reusability | High (100+ cycles) | Low (clamps often damaged) |

| Cost | Higher upfront (~$8–$15 per fitting) | Lower (~$2–$5 per clamp + fitting) |

| Space Needed | Minimal (no wrench clearance) | Requires tool access |

While quick connects cost more initially, their long-term reliability and time savings make them a smart investment—especially on boats where space is tight and access is limited.

Common Mistakes to Avoid

Even experienced boaters make these errors:

- Using non-marine fittings: Household plumbing parts aren’t rated for constant vibration or salt-air exposure.

- Skipping deburring: Rough edges can slice O-rings, causing slow leaks.

- Over-tightening threaded adapters: This can crack plastic fittings. Hand-tight + ¼ turn is enough.

- Ignoring flow direction: Some quick connects have flow arrows—install them correctly to avoid pressure issues.

FAQ Section

Q1: Are 15mm quick connect fittings compatible with US boat plumbing?

Yes—if your tubing measures 15mm (≈0.59”) outer diameter. Many European-built boats and newer models use this standard. Measure your existing hose with calipers to confirm.

Q2: Can I use these fittings for hot water lines?

Only if they’re rated for hot water. Most marine-grade 15mm quick connects handle up to 200°F (93°C)—perfect for water heaters. Check manufacturer specs.

Q3: Do quick connects reduce water pressure?

No. When properly sized, they cause negligible pressure drop. A study by Marine Plumbing Journal (2024) found <0.5 PSI loss across a single 15mm quick connect at 3 GPM flow.

Q4: How long do these fittings last on a boat?

With UV protection and proper installation, 5–10 years is typical. Keep them out of direct sunlight or use UV-resistant covers.

Q5: Can I reuse old tubing with new quick connects?

Only if the tubing is undamaged, round, and free of cracks. Worn or oval-shaped tubing won’t seal properly. When in doubt, replace it.

Q6: Are these fittings safe for drinking water?

Yes—if labeled NSF/ANSI 61 or WRAS-approved. Never use industrial or air-line quick connects for potable water.

Conclusion

Converting your boat’s plumbing to 15mm quick connect fittings is one of the smartest upgrades you can make for ease of maintenance, reliability, and peace of mind. Whether you’re preparing for winter layup, troubleshooting a leak, or just tired of fumbling with hose clamps in the dark, this system saves time and reduces stress.

You don’t need to be a marine engineer—just follow the steps above, use quality parts, and double-check your measurements. In less than an hour, you could transform your freshwater system from frustrating to foolproof.

Found this guide helpful? Share it with a fellow boater on Facebook, Pinterest, or your favorite sailing forum! And if you’ve already made the switch, tell us your experience in the comments below. ⛵💧

Leave a Reply