If you’ve ever stood on a construction site wondering how to determine the weight of plumb bob to use, you’re not alone. Choosing the wrong weight can lead to inaccurate readings, wasted time, or even safety issues—especially in windy conditions or tall structures. Whether you’re a DIY enthusiast or a seasoned contractor, getting this right is essential for precision and efficiency. In this guide, we’ll walk you through everything you need to know to select the perfect plumb bob weight for your project.

Why Does Plumb Bob Weight Matter?

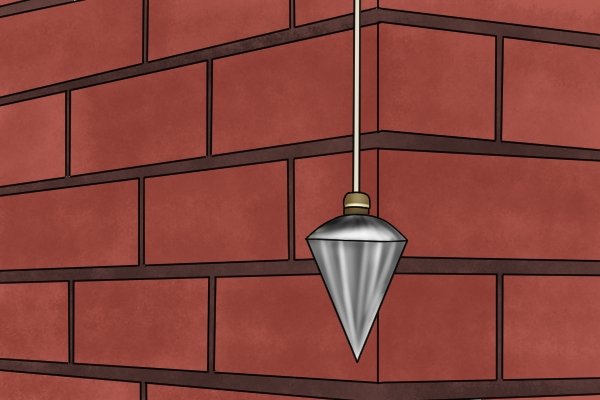

A plumb bob (or plummet) is a simple yet critical tool used to establish a true vertical reference line—known as a plumb line. Its weight directly affects stability, swing time, and resistance to environmental interference like wind or vibrations.

According to the National Institute of Standards and Technology (NIST), even minor deviations in vertical alignment can compound over height, leading to structural misalignments of several inches in high-rise buildings. That’s why selecting the correct weight isn’t just about preference—it’s about accuracy, safety, and compliance.

💡 Fun Fact: The word “plumb” comes from the Latin plumbum, meaning “lead”—the material originally used for these weights due to its high density.

For more on the history and physics of plumb bobs, see Wikipedia’s entry on plumb bobs.

How to Determine the Weight of Plumb Bob to Use: Key Factors

Choosing the right plumb bob weight depends on three main variables:

- Height of the drop

- Environmental conditions

- Required precision

Let’s break each down.

1. Height of the Drop

The taller the structure, the heavier the plumb bob you’ll need. A light bob will swing excessively and take too long to stabilize.

| Drop Height | Recommended Weight |

|---|---|

| Up to 10 ft (3 m) | 4–6 oz (113–170 g) |

| 10–30 ft (3–9 m) | 8–12 oz (227–340 g) |

| 30–60 ft (9–18 m) | 12–16 oz (340–454 g) |

| Over 60 ft (18+ m) | 16–24 oz (454–680 g) or more |

📌 Pro Tip: For drops over 50 feet, consider using a damping chamber or oil-filled container at the bottom to reduce oscillation.

2. Environmental Conditions

Wind, air currents, and nearby machinery can disrupt a plumb line. In outdoor or industrial settings, heavier is better.

- Indoors (calm): Standard weights suffice.

- Outdoors or near HVAC vents: Increase weight by 25–50%.

- High-wind zones (e.g., rooftops): Use 16 oz or more, and consider aerodynamic shapes (teardrop or bullet-style bobs).

3. Required Precision

Fine woodworking or tile installation may only need a 4–6 oz bob. But for structural steel framing or elevator shaft alignment, accuracy within 1/32 inch is often required—demanding heavier, more stable bobs.

Step-by-Step Guide: Choosing Your Plumb Bob Weight

Follow these steps to confidently select the right weight:

- Measure the vertical distance from your reference point to the target surface.

- Assess the environment: Is it indoors? Windy? Near heavy machinery?

- Determine your tolerance for error: Are you hanging drywall (±1/8″) or aligning a crane mast (±1/64″)?

- Consult the weight chart above based on your height range.

- Add 20% extra weight if conditions are less than ideal.

- Test before committing: Hang the bob and time how long it takes to stop swinging. Ideal stabilization: under 30 seconds.

✅ Real-World Example: A surveyor in Chicago used a 12 oz plumb bob for a 40-ft interior stairwell. When moving to an open atrium with crosswinds, they switched to a 20 oz brass bob—reducing alignment time by 60%.

Common Mistakes to Avoid

Even experienced pros slip up. Here’s what not to do:

- Using a too-light bob to “save time” → Leads to constant re-measuring.

- Ignoring line thickness → A heavy bob on thin thread can cause stretching or breakage. Match line strength to weight (e.g., 20 lb test for 16 oz+).

- Skipping the damping step → Letting the bob swing freely in open air wastes time.

- Assuming all bobs are equal → Brass and steel offer better density than plastic or aluminum.

Plumb Bob Materials & Weight Comparison

Not all plumb bobs are created equal. Material affects both weight and performance.

| Material | Density | Best For | Typical Weights |

|---|---|---|---|

| Brass | High | Precision work, durability | 6–24 oz |

| Steel | Very High | Heavy-duty, outdoor | 8–32 oz |

| Aluminum | Low | Lightweight indoor tasks | 2–8 oz |

| Plastic | Very Low | Temporary/DIY use | 1–4 oz |

⚠️ Note: Avoid plastic for professional applications—it’s prone to static, warping, and inconsistent weight distribution.

FAQ Section

Q1: Can I use a heavier plumb bob than recommended?

A: Yes—within reason. A heavier bob increases stability but requires a stronger line and more careful handling. Just ensure your string or wire can support the load without stretching.

Q2: What’s the most common plumb bob weight for general construction?

A: 12 ounces (340 g) is the industry standard for most residential and light commercial projects between 15–40 feet in height.

Q3: Does plumb bob shape affect performance?

A: Absolutely. Teardrop or conical shapes cut through air more cleanly, reducing sway. Flat-bottomed bobs are easier to mark but catch more wind.

Q4: How do I prevent my plumb bob from swinging?

A: Use a damping pan filled with water or light oil. Alternatively, let it hang for 1–2 minutes before marking. Some professionals wrap the line around a finger to gently absorb motion.

Q5: Can I make my own plumb bob?

A: You can—but it’s risky. Homemade weights often lack symmetry, causing spin or drift. For critical work, always use a calibrated, factory-made bob.

Q6: Are laser levels replacing plumb bobs?

A: Lasers are popular, but plumb bobs remain the gold standard for true verticality—especially over long distances or where power isn’t available. Many pros use both for cross-verification.

Conclusion

Knowing how to determine the weight of plumb bob to use is a small detail that makes a huge difference in construction accuracy. Whether you’re framing a wall or aligning a skyscraper core, the right weight ensures speed, safety, and precision.

Don’t guess—use the guidelines above to match your project’s height, environment, and tolerance needs. And remember: when in doubt, go slightly heavier. It’s far easier to manage a stable bob than to correct a crooked wall.

👉 Found this guide helpful? Share it with your crew on Facebook, LinkedIn, or Instagram! A quick share could save someone hours of rework—and maybe even prevent a costly mistake.

Stay plumb, stay precise.

Leave a Reply