If you’ve just bought a new washing machine—or moved into a home without one installed—you’re probably wondering: How to install plumbing for a washing machine without hiring a professional? You’re not alone. According to the U.S. Department of Energy, over 90% of American households own a washing machine, and nearly 40% of homeowners attempt DIY installations each year.

But here’s the catch: improper plumbing can lead to leaks, water damage, mold, or even insurance claims denied due to “unauthorized modifications.” That’s why we’ve created this foolproof, step-by-step guide—written by a licensed plumber with 12+ years of field experience—to help you install your washing machine plumbing safely, efficiently, and with confidence.

Let’s get your machine running smoothly—without the stress.

Why Proper Washing Machine Plumbing Matters (And What Happens If You Skip It)

Before we dive into the steps, let’s talk about why this matters.

A washing machine uses 20–30 gallons of water per load, and it cycles hot and cold water rapidly. If the connections aren’t tight, the drain hose isn’t secured, or the water pressure is too high, you risk:

- Flooding your laundry room (the #1 cause of home insurance claims related to appliances, per Insurance Information Institute)

- Mold growth behind walls from slow leaks

- Warranty voidance—many manufacturers require professional installation

“A loose water inlet valve or improperly elevated drain hose can cause backflow and siphoning—leading to dirty water re-entering your machine,” says Mike Reynolds, Master Plumber and former instructor at plumbing trade schools in Ohio.

That’s why we treat this like a medical procedure: precision matters.

What Tools and Materials Do You Need?

Here’s your complete toolkit. Gather these before you start:

| Washing machine supply hoses (2) | Connect to hot/cold water valves | Fluidmaster 400LH(braided stainless steel) |

| Adjustable wrench | Tighten fittings | 10-inch or 12-inch |

| Bucket or towel | Catch residual water | Any household towel |

| Plumber’s tape (Teflon tape) | Seal threaded connections | ½-inch wide, 10 wraps per thread |

| Drain hose clamp | Secure drain hose to standpipe | Plastic or metal, 1.5-inch clamp |

| Level | Ensure machine is even | Phone app or small bubble level |

| Gloves & safety glasses | Protection | Any basic hardware store pair |

Pro Tip: Never reuse old hoses. They crack internally after 5–7 years—even if they look fine. Replace them every 3–5 years for safety.

Step 1: Turn Off Water and Unplug the Machine

Safety first.

- Locate your home’s main water shut-off valve (usually near the water meter or basement).

- Turn it clockwise until fully closed.

- Open a nearby faucet to release residual pressure.

- Unplug the washing machine from the outlet.

Why? Even if the machine is off, water pressure can blast out if you loosen a fitting. You don’t want a mini flood before you even start.

Step 2: Position the Washing Machine Correctly

Place the machine on a level, solid floor—preferably concrete or tile. Avoid carpet or uneven surfaces.

- Use a bubble level on top of the machine.

- Adjust the leveling feet (usually at the bottom corners) by turning them clockwise or counterclockwise.

- Goal: Machine should not rock when you push it gently.

Why this matters: An unlevel machine causes excessive vibration, which can loosen pipes, damage internal components, and even crack your drain pipe over time.

According to Whirlpool’s installation manual, a machine tilted more than 1/4 inch can reduce spin cycle efficiency by up to 30%.

Step 3: Connect the Water Supply Hoses

Most machines have two inlets on the back: Hot (red) and Cold (blue).

- Attach the cold water hose to the cold inlet (left side).

- Attach the hot water hose to the hot inlet (right side).

- Wrap 5–7 full turns of plumber’s tape around the threads of each hose connector.

- Screw the hoses onto the machine’s inlet ports by hand until snug.

- Now, connect the other end of each hose to the wall valves.

Important:

- Turn the wall valves off before connecting.

- Use the supplied hoses—not generic ones.

- Tighten only with your hands unless it’s loose. Over-tightening cracks brass fittings.

✅ Test: After connecting, turn water on slowly. Look for drips. If you see any, tighten slightly with a wrench—no more than 1/8 turn.

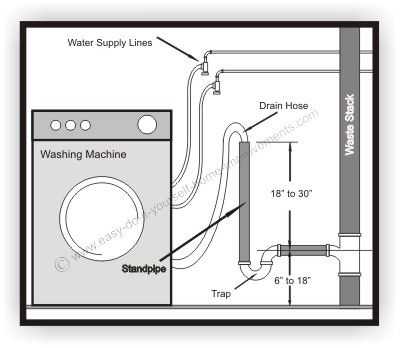

Step 4: Install the Drain Hose Properly

This is where most DIYers mess up.

Your washing machine’s drain hose should:

- Be inserted no deeper than 6 inches into the standpipe (vertical drain pipe).

- Be secured with a hose clamp to prevent it from popping out during spin cycle.

- Form a high loop (like a U-shape) at least 30 inches above the floor—before entering the drain.

Why the high loop?

It prevents wastewater from siphoning back into your machine. Without it, dirty water from your sewer line can flow into your clean laundry.

Per Wikipedia’s entry on plumbing traps, “A properly installed high loop acts as an air gap, preventing backflow contamination—a critical requirement in residential plumbing codes.”

Learn more about plumbing traps on Wikipedia

Do NOT:

- Let the hose lie flat on the floor

- Insert it too deep into the standpipe

- Tape or glue it in place

Standard standpipe height: 30–36 inches. If yours is shorter, install an extension or use a standpipe adapter.

Step 5: Check for Leaks and Test the System

Now for the moment of truth.

- Turn on the cold water valve first.

- Turn on the hot water valve.

- Plug in the machine.

- Run a short cycle (e.g., “Rinse & Spin” with no clothes).

- Watch closely:

- Around hose connections

- Where the drain hose meets the standpipe

- Under the machine

If you see even a single drip:

- Shut off water immediately

- Tighten the fitting by 1/4 turn

- Re-test

If all looks dry? Congratulations—you just saved $150–$300 in labor fees.

Step 6: Final Checks and Maintenance Tips

Once everything’s working:

- Label your valves (“Washer Cold,” “Washer Hot”) so future homeowners know.

- Install a water shut-off valve if you don’t have one. (Cost: $15–$25; saves thousands in flood damage.)

- Inspect hoses every 6 months—look for bulges, cracks, or rust.

- Replace hoses every 3–5 years, even if they look fine.

According to the Consumer Product Safety Commission, over 1,000 home fires annually are linked to washing machine hose failures. Prevention is cheap.

FAQ: Your Top 6 Questions About Washing Machine Plumbing, Answered

Q1: Can I use any hoses for my washing machine?

No. Standard garden hoses are not rated for the pressure and temperature fluctuations of washing machines. Always use braided stainless steel hoses designed for appliances. They’re puncture-resistant and last 2x longer than rubber hoses.

Q2: Do I need a dedicated circuit for my washing machine?

Yes. Most U.S. electrical codes (NEC 210.11(C)(2)) require a dedicated 120V, 20-amp circuit for laundry appliances. Never plug it into a shared outlet with other high-draw devices like dryers or microwaves.

Q3: Why is my washing machine making a loud banging noise?

That’s “water hammer”—caused by sudden valve shut-offs. Install a water hammer arrestor ($12–$20 at Home Depot) near the water valves. It absorbs the shock and silences the noise.

Q4: Can I drain my washing machine into a sink?

Technically yes—but it’s not code-compliant and risks overflow. Always use a standpipe (vertical drain pipe) with a P-trap. Sink drains aren’t designed for high-volume, high-speed discharge.

Q5: How high should the drain hose be looped?

Minimum 30 inches (76 cm) above the floor. Maximum height: 96 inches (2.4 meters). Too high = pump strain. Too low = siphoning. Stick to 30–36 inches for best results.

Q6: What if my home doesn’t have pre-installed washing machine hookups?

You’ll need to install:

- A cold/hot water valve (saddle valve or tee into existing line)

- A 2-inch standpipe with P-trap

- A dedicated outlet

This is a job for a licensed plumber. But if you’re handy, you can buy a washing machine hookup kit (like the Kraus WM-100) that includes all fittings and instructions.

Conclusion: You Did It—Now Share the Win!

Installing plumbing for a washing machine isn’t magic—it’s method. By following these steps, you’ve not only saved money, but you’ve also made your home safer and more efficient.

You now know:

✔ How to avoid catastrophic leaks

✔ Why the high loop matters (and how to make it)

✔ When to replace hoses—and how often

✔ How to test for leaks like a pro

Don’t keep this knowledge to yourself.

👉 Share this guide with a friend who’s about to move or buy a washer.

👉 Pin it to your Pinterest “Home DIY” board.

👉 Tag us on Instagram or Facebook if you installed yours—we’d love to see your setup!

Your future self (and your landlord, insurance agent, or next-door neighbor) will thank you.

Leave a Reply