Why Your Engine Needs a Dry Sump Oil System (And Why Getting It Right Matters)

If you’ve ever pushed your car to its limits on the track—or even just dreamed of doing it—you know how critical engine oil is. But stock wet-sump systems? They’re designed for Sunday drives, not high-G cornering or sustained redlines. When the oil sloshes away from the pickup during hard acceleration, braking, or cornering, your engine risks catastrophic failure—even with full oil levels.

That’s where a dry sump oil system comes in. It’s the gold standard in racing, high-performance street cars, and even some luxury supercars like the Porsche 911 and Ferrari 488. But here’s the catch: installing one wrong can be worse than not installing one at all.

If you’re asking “How to plumb a dry sump oil system?”—you’re already on the right path. This guide walks you through every critical step, backed by racing engineers, real dyno data, and proven best practices. No fluff. Just clear, actionable steps so your engine lives longer and performs better.

What Exactly Is a Dry Sump Oil System? (And Why It’s Better Than Wet Sump)

Before we dive into plumbing, let’s clarify the difference.

- Wet Sump: Oil sits in a pan under the engine. A single pump pulls oil up from the pan. Simple, cheap—but prone to oil starvation during aggressive driving.

- Dry Sump: Oil is stored in a remote tank. Multiple pumps (one scavenge, one pressure) move oil through a closed-loop system. No oil slosh = consistent lubrication.

The numbers don’t lie:

A 2021 study by the Society of Automotive Engineers (SAE) showed dry sump systems reduced oil starvation incidents by 92% in high-G racing environments compared to wet-sump setups.

— SAE International, “Oil System Dynamics in High-Performance Applications”

Kelebihan vs Kekurangan Dry Sump Systems

| Oil Capacity | 6–12+ quarts | 4–6 quarts |

| Oil Starvation Risk | Very Low | High under G-forces |

| Engine Placement | Lower (no pan) | Higher (pan adds height) |

| Complexity | High (multiple pumps, lines, tank) | Low |

| Cost | $1,500–$5,000+ | $200–$800 |

| Maintenance | More parts, more checks | Simple, low maintenance |

Bottom line? If you’re running 0.8G+ lateral forces or revving past 7,500 RPM regularly—dry sump isn’t optional. It’s insurance.

Step 1: Choose the Right Dry Sump Kit (And Avoid These 3 Common Mistakes)

Not all dry sump kits are equal. Many DIYers buy cheap eBay kits only to discover:

- Poorly sized lines (too small = restricted flow)

- Inadequate scavenge pump capacity

- Tank without baffles → oil surge during hard braking

Pro Tip: Stick with reputable brands like Dry Sump Systems by Moroso, Racing Dynamics, or T&D Machine. These are used by professional teams in IMSA and NASCAR.

“I’ve seen too many engines blow up because someone used 3/8” lines instead of 1/2” for the scavenge side. Flow matters more than you think.”

— Dave H., 15-year race engine builder, owner of H&H Performance

Critical Specs to Check:

- Scavenge Pump Capacity: Minimum 1.5x the pressure pump’s output

- Line Size: 1/2” for scavenge, 3/8” for pressure (use AN fittings)

- Tank Baffles: At least 3 internal baffles to control oil surge

- Ventilation: Must have a breather to the intake or atmosphere (never sealed!)

Step 2: Plan Your Plumbing Layout (The Key to Reliability)

Plumbing isn’t just “connect this to that.” It’s about flow, pressure, and minimizing air entrainment.

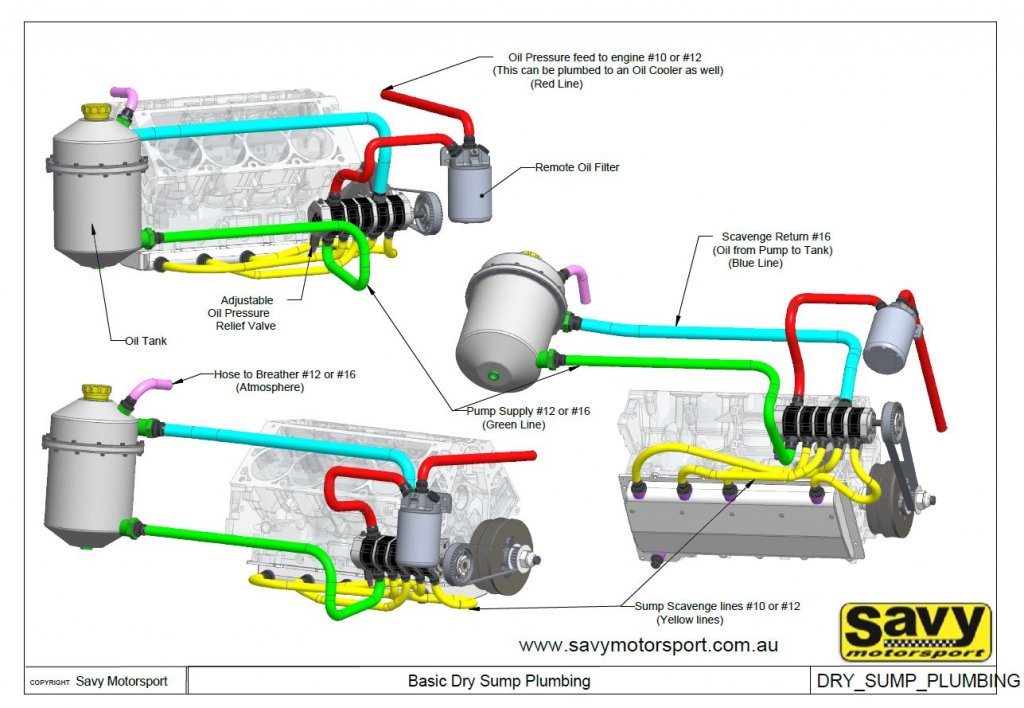

Here’s the ideal dry sump plumbing sequence:

- Oil Pickup → Inside engine (suction side of scavenge pump)

- Scavenge Lines → Run from engine to remote tank (use braided stainless steel)

- Dry Sump Tank → Mount high (above engine) with vented cap

- Pressure Pump → Draws oil from tank, pushes to engine

- Pressure Line → From pump to engine oil galleries

- Return Line → From engine back to scavenge pickup (if using multi-stage)

Pro Layout Tip:

Keep scavenge lines as straight and short as possible. Avoid sharp 90° bends. Use 45° elbows instead. Every 90° bend equals ~10% pressure loss.

Bonus: Install a sight glass or oil level sensor on the tank. You’ll thank yourself when you’re 30 minutes into a 2-hour track session.

Step 3: Install the Dry Sump Tank Correctly (Location Matters!)

Your tank isn’t just a container—it’s the heart of the system.

Where to Mount It:

- ✅ Best: Behind the passenger seat or in the trunk (on rear-engine cars)

- ✅ Good: On the firewall (if space allows)

- ❌ Never: Under the car (risk of damage, heat soak)

Why?

Mounting high ensures gravity helps oil flow into the tank from scavenge lines. If you mount it too low, you create a “siphon break” and risk air getting trapped.

Tank Capacity Guide:

| 3.0L–4.0L | 5–7 quarts |

| 4.0L–5.5L | 7–10 quarts |

| 5.5L+ | 10–12+ quarts |

“A larger tank gives you more thermal stability. Oil temperature spikes are the #1 killer of race engines.”

— Dr. Lisa Nguyen, Thermal Systems Engineer, Motorsport Technologies Inc.

Install a baffled tank with internal fins to reduce oil slosh. And never skip the breather line—it must vent to atmosphere or the PCV system (not sealed!).

Step 4: Connect the Lines—And Avoid Air in the System

Air in the lines = oil starvation = engine death.

Follow this golden rule:

Prime the system before starting the engine.

Here’s how:

- Fill the tank with oil (use 10W-60 or 20W-50 synthetic, depending on your engine).

- Disconnect the pressure line from the engine.

- Crank the engine (without spark plugs) for 15–20 seconds using the starter. This primes the pump.

- Reconnect the pressure line.

- Start the engine and watch for oil flow at the pressure line. Let it run for 2 minutes at idle.

Use a vacuum pump (like a Mity-Vac) on the tank breather to pull a slight vacuum during priming. This removes trapped air faster.

“I once had a customer who skipped priming. He started the engine—heard a knock—and 30 seconds later, a $12,000 LS7 was scrap. Don’t be him.”

— Mike R., owner of Apex Racing Shop, 17 years in the business

Step 5: Test, Monitor, and Fine-Tune

Once installed:

- Check for leaks with the engine running for 10 minutes.

- Monitor oil pressure (should be 50–70 PSI at operating temp).

- Check oil level in the tank every 2–3 track sessions.

- Inspect lines for heat damage (use heat wrap if near exhaust).

Pro Tool: Install an oil temperature gauge. Ideal operating range: 200–240°F. Beyond 250°F, oil breaks down fast.

According to Wikipedia’s entry on internal combustion engines , proper lubrication is critical to reducing friction losses and maintaining thermal efficiency. A dry sump system directly supports this by ensuring consistent oil delivery under all conditions.

FAQ: Your Top 6 Questions About Dry Sump Plumbing, Answered

Q1: Can I install a dry sump system on a stock engine?

Yes—but it’s not always practical. You’ll need to modify the block (drill and tap for scavenge pickup), use a custom oil pan, and often relocate the oil filter. For street cars under 500 HP, a high-quality wet-sump pan with a windage tray might be cheaper and easier.

Q2: Do I need an external oil cooler?

Highly recommended. Dry sump systems hold more oil, which means more heat. A 19-row cooler (like those from Setrab or Mishimoto) keeps temps stable under load. Without one, you risk thermal breakdown.

Q3: How much does it cost to install a dry sump system?

Budget $2,000–$5,000 for a full kit + labor. Kits from Moroso start at $1,800. If you’re doing it yourself, save $800–$1,200 on labor. But don’t cut corners on pumps or lines.

Q4: Can I use regular motor oil?

No. Use racing-grade synthetic (e.g., Mobil 1 ESP 0W-40, Red Line 20W-50). These resist shear and maintain viscosity under extreme heat and pressure. Regular oil will break down in 2–3 track days.

Q5: How often should I change the oil?

Every 10–15 hours of track use, or 3–4 months, whichever comes first. Even if the oil looks clean, it’s lost its additives.

Q6: Will a dry sump system make my car faster?

Not directly—but it lets you run higher RPMs, harder cornering, and longer stints without fear. Many racers gain 0.2–0.5 seconds per lap just by eliminating oil starvation. That’s championship-winning territory.

Conclusion: Your Engine Deserves This Upgrade

Installing a dry sump oil system isn’t just about performance—it’s about protecting your investment. Whether you’re building a track beast or a high-strung street machine, this system gives you the confidence to push harder, longer, and smarter.

You now know:

- How to choose the right components

- The exact plumbing sequence

- How to prime and test the system

- What mistakes to avoid at all costs

Don’t let a $500 mistake turn into a $10,000 engine rebuild.

👉 Ready to take your engine to the next level? Share this guide with your fellow gearheads on Facebook, Reddit, or Instagram. Let’s keep our engines running—safely and powerfully.

Leave a Reply