Replacing or installing a new kitchen sink and dishwasher can feel overwhelming—especially when you’re working with copper pipes, known for their durability but tricky to handle without experience. If you’ve ever asked yourself, “How do I plumb a kitchen sink and dishwasher in copper correctly and safely?” you’re not alone. Many homeowners tackle this project to save money or gain hands-on control over their home’s infrastructure. In this guide, we’ll walk you through the entire process with clarity, confidence, and code-compliant best practices.

Why Choose Copper for Kitchen Plumbing?

Copper has been a gold standard in residential plumbing since the 1960s. According to the U.S. Department of Energy, copper piping lasts 50+ years when properly installed and is highly resistant to corrosion, bacteria growth, and high water pressure.

Key benefits include:

- Longevity: Outlasts PEX and PVC in many applications

- Heat resistance: Ideal for hot water lines (dishwashers need 120°F+ supply)

- Recyclability: Over 80% of copper used in construction is recycled (source: Wikipedia)

- Code compliance: Accepted by all major U.S. plumbing codes (IPC & UPC)

However, copper requires soldering skills and precise measurements—making preparation essential.

Tools and Materials You’ll Need

Before turning off your water, gather these essentials:

| Category | Items |

|---|---|

| Tools | Tubing cutter, propane torch, emery cloth, pipe reamer, adjustable wrench, Teflon tape, bucket, heat shield |

| Materials | Type M or L copper tubing (½” for supply lines), copper fittings (elbows, tees, couplings), lead-free flux, lead-free solder, compression fittings (if avoiding solder), dishwasher air gap kit |

| Safety Gear | Heat-resistant gloves, safety goggles, fire extinguisher |

💡 Pro Tip: Always use lead-free solder and flux labeled “NSF/ANSI 61-G” for potable water systems—required by U.S. federal law since 2014.

Step-by-Step: Plumbing Your Sink & Dishwasher in Copper

Step 1: Shut Off Water and Drain Lines

- Turn off the main water supply.

- Open both hot and cold faucets to relieve pressure and drain residual water.

- Place a bucket under existing connections to catch drips.

Step 2: Remove Old Fixtures (If Applicable)

- Disconnect supply lines using an adjustable wrench.

- Unscrew mounting clips for the dishwasher.

- Cap or plug open pipes temporarily to prevent debris entry.

Step 3: Plan Your Layout

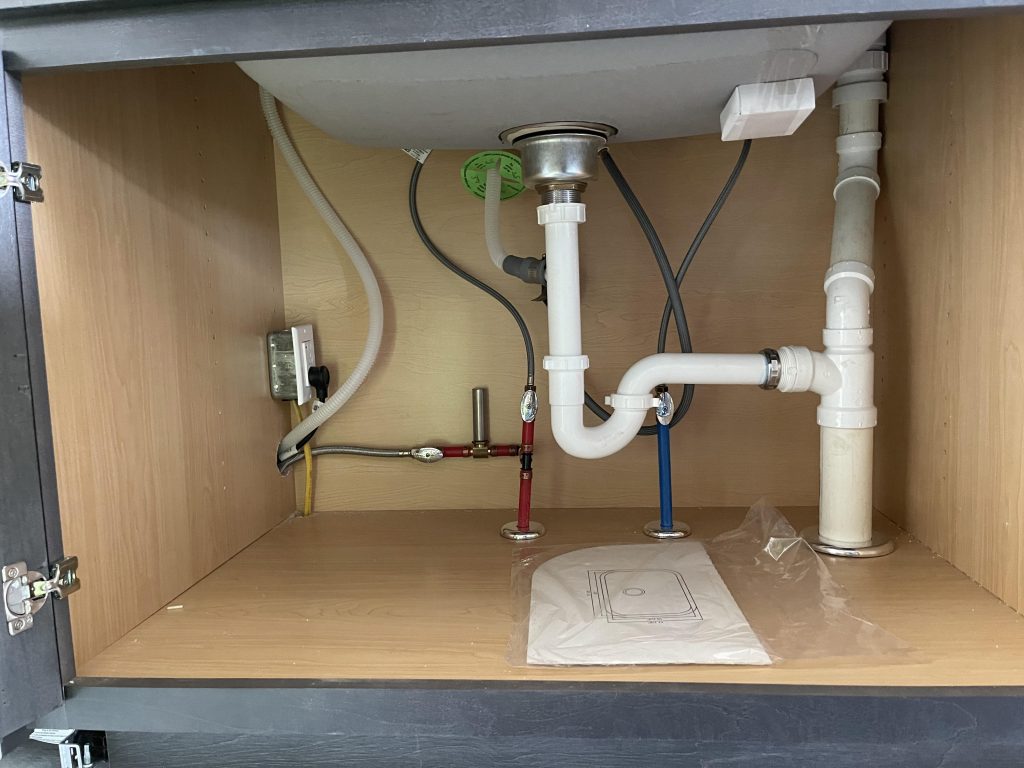

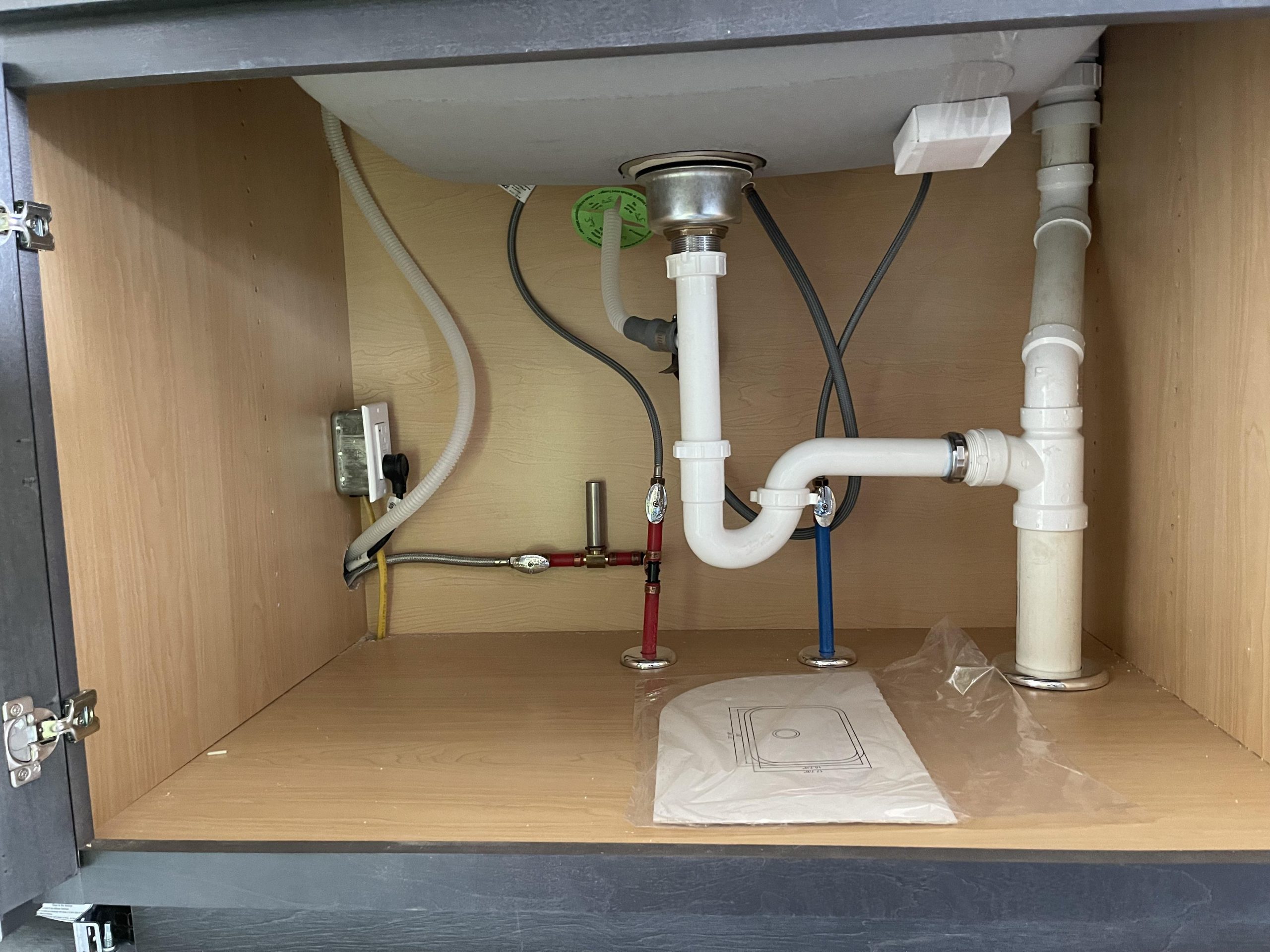

Sketch a simple diagram showing:

- Cold/hot supply lines from shutoff valves to faucet

- Dedicated hot water line from valve to dishwasher inlet

- Drain connection from dishwasher to sink tailpiece (via high loop or air gap)

⚠️ Code Note: Most U.S. jurisdictions require either a high loop (minimum 32″ above floor) or a mechanical air gap to prevent backflow contamination.

Step 4: Cut and Prepare Copper Tubing

- Measure twice, cut once with a tubing cutter (never hacksaw—it leaves burrs).

- Use a pipe reamer to remove internal ridges.

- Clean ends with emery cloth until shiny—this ensures proper solder adhesion.

Step 5: Dry-Fit All Connections

Assemble all fittings without solder to verify alignment and clearance under the sink. Adjust as needed—copper is rigid, so precision matters.

Step 6: Solder Joints (Sweat Fittings)

- Apply lead-free flux to cleaned pipe ends and inside fittings.

- Insert pipe into fitting fully.

- Heat fitting evenly with a propane torch (not MAPP gas—too hot for beginners).

- Touch solder wire to opposite side of joint; capillary action will draw it in.

- Wipe excess with a damp rag while warm (not hot).

🔥 Safety First: Use a heat shield behind pipes near cabinets to prevent fires. Keep a spray bottle of water nearby.

Step 7: Connect to Fixtures

- Attach supply lines to faucet using compression fittings or flexible braided hoses (many modern faucets don’t accept direct copper).

- For the dishwasher, connect copper supply line to its inlet valve (usually marked “Hot”).

- Link dishwasher drain hose to the sink tailpiece or air gap per local code.

Step 8: Pressure Test & Inspect

- Slowly turn water back on.

- Check every joint for leaks—no drips allowed.

- Run both faucet and dishwasher through a short cycle.

- Inspect again after 15 minutes.

Copper vs. PEX vs. PVC: Which Is Best for Kitchens?

| Feature | Copper | PEX | PVC |

|---|---|---|---|

| Durability | ★★★★★ (50+ yrs) | ★★★★☆ (30–50 yrs) | ★★★☆☆ (25–40 yrs) |

| Heat Resistance | Excellent (up to 400°F) | Good (up to 200°F) | Poor (not for hot water) |

| Installation Ease | Moderate (requires soldering) | Easy (crimp/clamp tools) | Easy (glue joints) |

| Cost (per ft) | $2.50–$4.00 | $0.50–$1.00 | $0.30–$0.70 |

| Backflow Safety | High (rigid, non-permeable) | Medium (can leach if exposed to sunlight) | Low (not for supply lines) |

📌 Verdict: Copper remains ideal for hot water supply lines to dishwashers due to heat tolerance and longevity—despite higher upfront cost.

Common Mistakes to Avoid

- Skipping deburring: Causes turbulence and weak joints

- Overheating joints: Burns off flux, leading to leaks

- Ignoring local codes: Some cities ban soldering near combustibles without permits

- Forgetting the air gap: Violates health codes in CA, TX, NY, and others

- Using acidic flux: Corrodes pipes over time—always use lead-free, rosin-based flux

FAQ Section

Q1: Can I connect a dishwasher directly to copper without a flexible hose?

A: Yes—but only if your dishwasher inlet accepts ⅜” or ½” copper. Most modern units require a flexible stainless steel braid for vibration absorption. Check your manual first.

Q2: Do I need a permit to replumb my kitchen in copper?

A: In most U.S. municipalities, yes—especially if altering supply lines. Permits ensure inspections for backflow prevention and proper slope on drains. Call your local building department.

Q3: What size copper pipe should I use?

A: ½-inch Type M is standard for residential sink and dishwasher supply lines. Type L (thicker wall) is overkill unless required by local code.

Q4: How do I fix a leaking copper joint?

A: Drain the line, heat the joint to melt old solder, disassemble, clean thoroughly, re-flux, and re-solder. Never just “add more solder” on top—it won’t bond.

Q5: Is copper safe for drinking water?

A: Absolutely—when installed correctly with lead-free materials. The EPA confirms copper poses no health risk at typical household concentrations (<1.3 mg/L).

Q6: Can I mix copper and PEX in the same system?

A: Yes! Use brass transition fittings (e.g., copper-to-PEX adapter). Ensure dielectric isolation to prevent galvanic corrosion.

Conclusion

Learning how to plumb a kitchen sink and dishwasher in copper empowers you to create a reliable, long-lasting plumbing system that meets health standards and stands the test of time. While it demands patience and attention to detail, the payoff is fewer leaks, better water quality, and peace of mind.

If this guide helped you avoid a costly plumber visit—or simply gave you confidence to start—share it with a friend tackling their own kitchen upgrade! Got questions? Drop them in the comments below.

🔧 Remember: When in doubt, consult a licensed plumber. Safety and code compliance always come first.

Leave a Reply