If you’re managing a commercial kitchen or setting up a janitorial closet in a food service facility, you’ve probably wondered: Can I connect my mop sink directly to a grease trap? The short answer is yes—but only if done correctly. Incorrect plumbing can lead to clogs, health code violations, and even costly fines from local authorities. In this guide, you’ll learn exactly how to plumb a mop sink into a grease trap the right way, following current plumbing codes and best practices used by licensed professionals across the U.S.

Why Should a Mop Sink Connect to a Grease Trap?

Many assume mop sinks are “clean water” drains and can go straight to the sewer. But in commercial settings—especially restaurants, cafeterias, or food processing areas—mop water often contains residual grease, food particles, and cleaning chemicals. If this wastewater enters the main sewer without treatment, it contributes to fatbergs, pipe blockages, and environmental contamination.

According to the EPA, grease-related blockages cause 47% of all sanitary sewer overflows in the U.S. annually. That’s why most municipal plumbing codes (like the Uniform Plumbing Code [UPC] and International Plumbing Code [IPC]) require all fixtures in food service areas—including mop sinks—to drain through a grease interceptor.

💡 Expert Insight: “Even ‘clean’ mop water from a kitchen floor can carry invisible grease films. Routing it through a grease trap isn’t optional—it’s a public health safeguard.”

— National Restaurant Association, 2023 Facility Compliance Report

Is It Legal to Connect a Mop Sink to a Grease Trap?

Yes—in most U.S. jurisdictions, it’s not only legal but required. However, specific rules vary by city and state. For example:

- California (Title 22): Mandates that all indirect waste from food prep areas (including mop sinks) must discharge into a grease retention device.

- New York City: Requires a separate grease trap for janitorial sinks within 10 feet of food handling zones.

- Texas (TPDES): Allows mop sink connections only if the grease trap is sized to handle the additional flow.

Always check with your local health department or building inspector before installation. When in doubt, consult a licensed plumber familiar with your area’s codes.

For a general overview of grease interceptor standards, see the Wikipedia entry on grease traps, which outlines design principles recognized by plumbing authorities nationwide.

Step-by-Step: How to Plumb a Mop Sink Into a Grease Trap

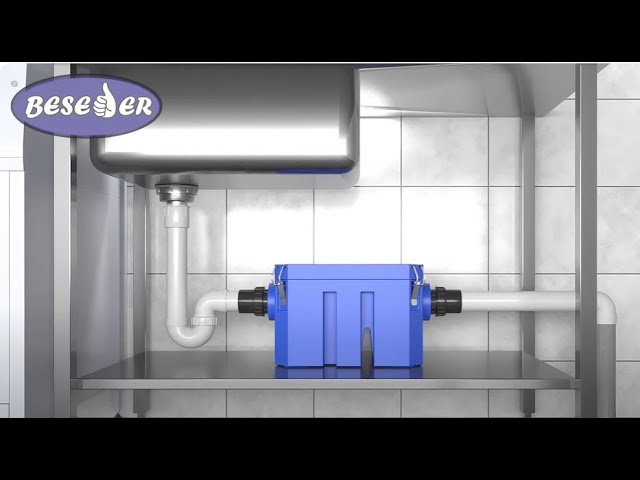

Follow these steps carefully. This process assumes you’re working with a hydromechanical grease trap (common under-sink units) or a gravity grease interceptor (larger in-ground tanks).

Tools & Materials Needed:

- PVC or ABS piping (typically 1.5″ or 2″ diameter)

- Pipe cutter or hacksaw

- PVC primer and cement

- P-trap (already installed under mop sink)

- Vent pipe (if required by code)

- Tape measure

- Level

- Local plumbing permit (if required)

Step 1: Confirm Drain Line Compatibility

- Most mop sinks use a 1.5-inch drain outlet.

- Your grease trap inlet should match or be larger (never smaller).

- Ensure the vertical drop from the sink to the trap is at least ¼ inch per foot for proper flow (per UPC 706.3).

✅ Pro Tip: Use a laser level to verify slope. A 4-foot run needs at least 1 inch of drop.

Step 2: Install a P-Trap (If Not Already Present)

Every fixture must have a P-trap to prevent sewer gases from entering the room. The trap should be:

- Installed directly under the sink

- Vented properly (usually via an air admittance valve or wet vent)

- Made of corrosion-resistant material (PVC or stainless steel)

Step 3: Run the Drain Line to the Grease Trap

- Measure the distance from the P-trap outlet to the grease trap inlet.

- Cut PVC pipe to length, ensuring a continuous downward slope.

- Dry-fit all connections first.

- Apply PVC primer, then cement, and join securely.

- Support pipes every 32 inches with hangers to prevent sagging.

⚠️ Critical: Never connect the mop sink downstream of the grease trap. It must enter before the trap’s baffle system so contaminants are captured.

Step 4: Maintain Proper Venting

Improper venting causes slow drainage and siphoning of the P-trap. Options include:

- Individual vent: Rises vertically and ties into the main vent stack.

- Air Admittance Valve (AAV): A one-way mechanical vent (allowed in many areas, but not all—check local code).

Step 5: Test for Leaks and Flow

- Fill the mop sink with 2 gallons of water.

- Open the drain and observe:

- Water should flow smoothly into the grease trap.

- No gurgling or backup.

- No leaks at joints after 10 minutes.

- Repeat with warm water (100°F / 38°C) to simulate real-world use.

Common Mistakes to Avoid

| Mistake | Consequence | Fix |

|---|---|---|

| Connecting after the grease trap | Grease bypasses interceptor | Re-route to inlet side |

| Flat or upward drain slope | Slow drainage, clogs | Re-pipe with ¼”/ft slope |

| Skipping the P-trap | Sewer gas infiltration | Install code-compliant trap |

| Overloading trap capacity | Reduced efficiency, overflow | Size trap for total fixture load |

📊 Did You Know? A standard 20-gallon hydromechanical grease trap can handle up to 10 GPM (gallons per minute). A typical mop sink drains at 3–5 GPM, so it’s usually compatible—but always calculate total fixture units.

Maintenance Tips After Installation

Once plumbed correctly, maintain your system:

- Pump the grease trap every 30–90 days (or when 25% full of FOG—fats, oils, grease).

- Never pour hot water or chemicals down the mop sink to “flush” grease—this melts solids and pushes them into the sewer.

- Inspect monthly for odors, slow drainage, or visible grease buildup.

FAQ Section

Q1: Can I connect a mop sink to a grease trap shared with a dishwasher or sink?

A: Yes—most commercial grease traps are designed to handle multiple fixtures. Just ensure the total flow rate doesn’t exceed the trap’s rated capacity (measured in GPM or fixture units).

Q2: Do I need a separate grease trap just for the mop sink?

A: Not usually. As long as your existing grease trap has sufficient capacity and the mop sink is in a food service area, you can tie it in. However, some health departments require isolation for janitorial sinks—verify locally.

Q3: What happens if I don’t connect the mop sink to a grease trap?

A: You risk violating health codes, which can result in fines ($500–$5,000+), failed inspections, or even temporary closure. Plus, grease buildup can cause expensive plumbing emergencies.

Q4: Can I use flexible tubing instead of rigid PVC?

A: No. Flexible hoses (like dishwasher connectors) are not approved for permanent drain lines under UPC/IPC. They sag, trap debris, and fail inspection.

Q5: Does the mop sink need its own vent?

A: Yes—every trap needs a vent to equalize pressure. You can share a vent with nearby fixtures if within code-specified distances (e.g., UPC allows wet venting within 5 feet).

Q6: How do I size a grease trap for a mop sink?

A: Calculate total drainage fixture units (DFUs). A mop sink = 2 DFUs. Add to other fixtures (e.g., 3-compartment sink = 9 DFUs). Use the total to select a trap per manufacturer charts or local code tables.

Conclusion

Knowing how to plumb a mop sink into a grease trap isn’t just about pipes and fittings—it’s about protecting your business, your customers, and the environment. Done right, this setup ensures compliance, prevents costly backups, and keeps your kitchen running smoothly.

If you found this guide helpful, share it with fellow restaurant owners, facility managers, or DIYers on social media! A quick tweet or Facebook post could save someone from a $3,000 plumbing disaster.

🔧 Remember: When in doubt, hire a licensed plumber. Your local health inspector won’t accept “I read it online” as an excuse—but they will appreciate a properly installed system.

Stay compliant. Stay clean. Keep your drains flowing.

Leave a Reply