Imagine waking up to a flooded bathroom because a pipe burst overnight—or worse, realizing your new vanity sink leaks every time you turn on the faucet. You’re not alone. According to the U.S. Department of Housing and Urban Development, over 14% of American homes experience plumbing leaks each year, costing homeowners an average of $3,000 in repairs.

If you’re thinking about how to plumb a toilet, sink, and shower yourself, you’re not just saving money—you’re taking control of your home’s safety and functionality. Whether you’re renovating a guest bath or building from scratch, this guide breaks down everything you need to know—step by step, in plain English—with no jargon, no guesswork.

Let’s get your bathroom flowing smoothly—safely and correctly.

Why Proper Plumbing Matters More Than You Think

Before we dive into tools and techniques, let’s talk about why this matters.

Improperly plumbed fixtures don’t just leak—they can cause mold growth, structural rot, and even electrical hazards if water reaches wiring. The International Residential Code (IRC) requires all bathroom plumbing to be sloped, vented, and pressure-tested to prevent backflow and siphoning.

“A poorly installed shower drain can back up into your toilet. That’s not just messy—it’s a health hazard.”

— Mike Holmes, Master Plumber & TV Host

The good news? With the right knowledge, you can avoid these pitfalls. In fact, a 2023 survey by HomeAdvisor found that 68% of DIYers who completed their own bathroom plumbing reported higher satisfaction than those who hired pros—if they followed code.

What Tools and Materials Do You Need?

You don’t need a professional toolbox—but you do need the essentials. Here’s your checklist:

| Pipe cutter | Clean cuts on PVC, copper | Ridgid Pipe Cutter |

| Adjustable wrench | Tightening nuts on supply lines | Stanley FatMax |

| Plumber’s putty | Sealing sink drains | Oatey Plumber’s Putty |

| P-trap assembly | Traps water to block sewer gas | NIBCO PVC P-trap |

| Silicone caulk | Waterproofing around fixtures | GE Silicone II |

| Pipe tape (Teflon) | Sealing threaded connections | Hercules Teflon Tape |

| Level | Ensuring fixtures are straight | Stabila Laser Level |

| Bucket & towels | Catching water during tests | — |

Pro Tip: Always turn off the main water supply before starting. And if you’re working with copper pipes, you’ll need a propane torch and solder—only if you’re experienced. For beginners, stick with PEX or PVC.

Step 1: Plan Your Layout (Code-Compliant Design)

You can’t just hook up pipes randomly. Plumbing must follow slope, venting, and spacing rules:

- Toilet drain pipe: Must slope 1/4 inch per foot toward the main sewer line.

- Sink drain: Needs a P-trap within 24 inches of the fixture (IRC P2707.1).

- Shower drain: Must be centered and slope 1/8 inch per foot to the drain.

- Vent pipes: Must extend through the roof and be at least 6 inches above the flood rim.

Visual Tip: Sketch your layout on graph paper. Use 1 square = 1 foot. Label where each fixture connects to the main stack.

Fun fact: The modern P-trap was invented in 1880 by Thomas Crapper’s team to prevent sewer gases from entering homes. Today, it’s still the #1 defense against foul odors. Learn more on Wikipedia

Step 2: Install the Toilet First (The Anchor Fixture)

The toilet is your starting point. Everything else connects around it.

Tools Needed: Wax ring, closet flange bolts, adjustable wrench, level

Steps:

- Shut off water and flush the toilet to drain the tank.

- Remove old flange if damaged. Install a new PVC or cast iron closet flange secured to the floor with screws.

- Place a new wax ring (or wax-free alternative like a rubber gasket) on the flange.

- Lower the toilet bowl straight down onto the flange—don’t twist! Press firmly to seal.

- Insert bolts through the base, add washers and nuts. Tighten alternately—don’t overtighten or you’ll crack porcelain.

- Attach the tank, connect the water supply line (use a braided stainless steel line—lasts longer than plastic).

- Turn water back on. Flush 3 times. Check for leaks under the base.

✅ Success Check: No water pooling. No wobble. Toilet should be level (use a 6-inch level).

Step 3: Plumb the Bathroom Sink (The Most Common DIY Mistake)

Most leaks happen here—because people skip the P-trap or install it backward.

Tools Needed: P-trap kit, pipe cutter, plumber’s putty, bucket

Steps:

- Mount the sink to the vanity. Use silicone caulk around the edges.

- Connect the tailpiece (the vertical pipe under the drain) to the sink’s drain outlet. Use plumber’s putty underneath the flange.

- Attach the P-trap:

- One end to the tailpiece.

- Other end to the wall drainpipe.

- Use slip nuts and washers—hand-tighten, then give a quarter-turn with pliers.

- Test: Fill the sink with 2 liters of water (about 22–28°C / 72–82°F). Let it drain. Look for drips under the trap.

- Seal the overflow (if present) with silicone to prevent moisture behind the sink.

⚠️ Common Mistake: Don’t use PVC cement on slip joints. It’s only for glued joints. Slip joints need rubber washers.

Step 4: Install the Shower Drain and Pipes

Shower plumbing is tricky because water volume is high—and slope is critical.

Tools Needed: Shower drain assembly, PVC primer & cement, measuring tape, level

Steps:

- Cut the subfloor to fit the drain flange. Use a jigsaw.

- Install the shower drain body (like a Oatey or Sioux Chief model). Secure it with screws into the framing.

- Apply PVC primer and cement to the drain outlet and connect it to the 2-inch drain pipe sloping 1/8 inch per foot toward the main sewer line.

- Build a sloped mud bed (if tiling) or install a pre-sloped pan (for prefab showers).

- Connect the P-trap to the drain line. Use a 2-inch trap (never 1.5-inch—it won’t handle shower flow).

- Test with 5 gallons of water poured slowly. The water should drain in under 15 seconds. If it pools, your slope is wrong.

Pro Tip: Use a dry fit first—assemble all pipes without glue. Adjust angles, then disassemble, glue, and reassemble.

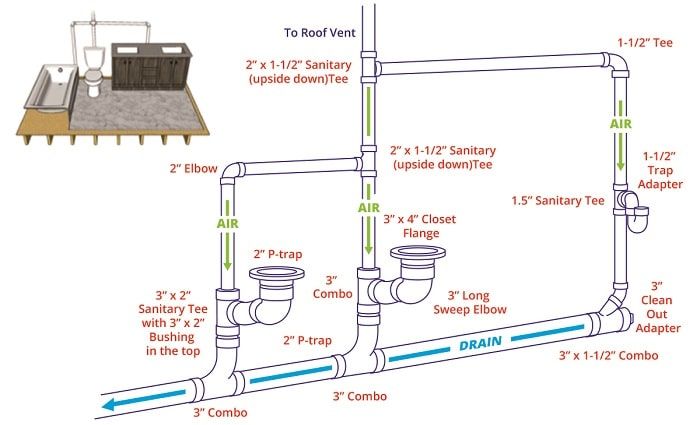

Step 5: Connect All Fixtures to the Main Stack

Now, link your toilet, sink, and shower drains to the main vertical drain pipe (the “stack”).

- Toilet drain: Usually 3–4 inch pipe.

- Sink & shower: 1.5–2 inch pipes.

- All must connect via a wye fitting, not a tee (tees cause clogs).

Critical Rule: Every drain needs a vent within 5 feet. The vent allows air in so water flows smoothly. Without it, you’ll hear gurgling—and the P-trap will siphon dry.

“A dry trap means sewer gas enters your home. That’s not just smelly—it’s dangerous.”

— National Association of Home Builders (NAHB)

Use a stud finder to locate wall studs before cutting into drywall. Drill a 2-inch hole, insert the vent pipe, and cap it with a roof vent (or air admittance valve if local code allows).

Step 6: Pressure Test & Final Inspection

Before closing walls:

- Cap all open ends of your drain lines.

- Fill the system with water from a hose until it reaches the top of the highest fixture (usually the sink).

- Wait 15 minutes. If the water level drops, you have a leak.

- Check every joint with a flashlight and paper towel. Wet spots = leaks.

- If everything holds, you’re ready to tile, drywall, and finish.

Bonus: Take a photo of your plumbing layout before covering it up. You’ll thank yourself when you need to fix something in 5 years.

FAQ: Your Top 6 Questions Answered

Q1: Can I plumb a toilet, sink, and shower myself?

Yes—if you follow code, use the right materials, and test thoroughly. Most homeowners complete this in 2–3 days. Just don’t skip the pressure test.

Q2: What’s the cheapest way to plumb a bathroom?

Use PEX tubing for water supply (easy to route) and PVC for drains. Avoid copper unless you’re experienced with soldering. PEX costs 40% less and installs 3x faster.

Q3: Do I need a permit to plumb my own bathroom?

In most U.S. states, yes. Check with your local building department. Unpermitted work can void your home insurance and block resale.

Q4: Why does my shower drain gurgle when I flush the toilet?

That’s a sign your vent pipe is blocked or missing. The toilet’s rush of water creates negative pressure, sucking air through the shower trap. Install or clear the vent.

Q5: How deep should the P-trap be under the sink?

The vertical leg of the P-trap should be 2–4 inches below the sink’s outlet. Too shallow = poor seal. Too deep = slow drainage.

Q6: Can I use the same drain line for the sink and shower?

Only if local code allows it (some do, some don’t). Best practice? Use separate drains that tie into a single 3-inch stack. This prevents clogs and meets most IRC standards.

Conclusion: You’ve Got This

Learning how to plumb a toilet, sink, and shower isn’t about being a genius—it’s about being careful, patient, and code-savvy. You’ve now learned how to avoid the 5 most common mistakes, use the right tools, and pass an inspection.

You’re not just installing pipes—you’re protecting your home, your health, and your wallet.

Ready to share your win?

👉 Tag a friend who’s planning a bathroom remodel.

👉 Pin this guide to your Pinterest “DIY Bathroom” board.

👉 Leave a comment below with your biggest plumbing win—or question!

Your bathroom is about to become the most reliable room in your house. And you did it—with your own two hands.

Leave a Reply