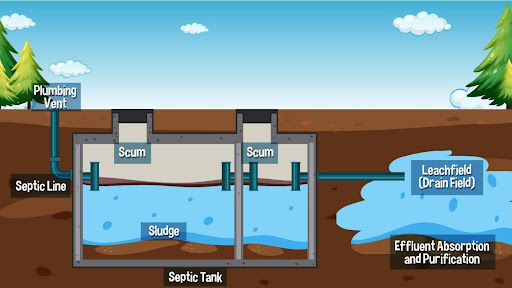

If you’re planning to install or repair a septic system, understanding how to plumb the inside of a septic tank diagram is essential. Many homeowners dive into this project without realizing the complexity—and consequences—of improper plumbing. A well-designed internal layout ensures efficient waste separation, prevents backups, and complies with local health codes. In this guide, we’ll walk you through everything you need to know, from inlet/outlet placement to baffle installation, using clear diagrams and real-world best practices.

What Does “Plumbing the Inside of a Septic Tank” Mean?

“Plumbing the inside” refers to configuring the internal components that manage wastewater flow within the tank—not the pipes leading to your house or drain field. This includes:

- Inlet and outlet pipes

- Baffles or tees

- Effluent filters (if used)

- Gas deflection mechanisms

These elements work together to separate solids from liquids, prevent scum from escaping, and allow only clarified effluent to exit toward the drain field.

💡 Did You Know? According to the EPA, over 20% of septic system failures are due to poor internal tank design or incorrect plumbing—often because baffles are missing or misaligned.

Why Is an Accurate Septic Tank Diagram Critical?

A precise how to plumb the inside of a septic tank diagram serves three key purposes:

- Code Compliance: Most U.S. states follow guidelines from the Environmental Protection Agency (EPA) or local health departments. Your design must meet these standards.

- System Longevity: Proper internal plumbing reduces sludge buildup and prevents clogs.

- Inspection Readiness: Health inspectors check internal configurations during permits or property sales.

Without a correct diagram, even a professionally installed tank can fail within 2–3 years.

Step-by-Step: How to Plumb the Inside of a Septic Tank

Follow these steps to ensure your internal plumbing aligns with industry standards and regulatory requirements.

Step 1: Understand Tank Anatomy

Most residential septic tanks are two-compartment (or dual-chamber) concrete or polyethylene units. Key zones:

| Component | Function |

|---|---|

| Inlet Chamber | Receives raw sewage; allows solids to settle |

| Outlet Chamber | Holds partially treated effluent before it exits |

| Baffle Wall | Separates chambers; has a submerged opening (~14″ below surface) |

📏 Pro Tip: The inlet pipe should be 2–3 inches higher than the outlet pipe to maintain proper hydraulic gradient.

Step 2: Install the Inlet Baffle

- Use a sanitary tee or concrete baffle.

- Position it so the vertical leg extends at least 6 inches below the liquid surface and 12 inches above the sludge layer.

- Angle the horizontal arm toward the tank wall to diffuse incoming flow and reduce turbulence.

⚠️ Warning: Without a baffle, incoming waste can stir up settled sludge, sending solids into the drain field—causing clogs and system failure.

Step 3: Set Up the Outlet Assembly

- Install a 90-degree elbow or sanitary tee on the outlet side.

- Add an effluent filter (recommended by many state codes, including Florida and Washington).

- Ensure the outlet pipe sits 2–4 inches below the liquid surface but above the sludge line.

🔍 Real-World Example: A 2022 study by the National Small Flows Clearinghouse found homes with effluent filters had 40% fewer drain field failures over 5 years.

Step 4: Seal All Penetrations

- Use butyl rubber gaskets or polyurethane sealant around pipe entries.

- Never use standard PVC cement—it degrades in anaerobic environments.

Step 5: Verify Ventilation

While not part of plumbing per se, proper venting prevents pressure buildup. Gases should escape via the roof vent stack, not the tank itself. Never cap the tank completely.

🌬️ Note: Methane and hydrogen sulfide gases are naturally produced. A sealed tank without ventilation risks explosion or odor backup.

Common Mistakes to Avoid

Even experienced DIYers make these errors:

- ❌ Skipping baffles to save cost or time

- ❌ Using flexible corrugated pipe inside the tank (it collapses under load)

- ❌ Placing inlet and outlet at the same height (causes short-circuiting)

- ❌ Ignoring local codes—e.g., some counties require dual filters or alarm systems

Always consult your county health department before finalizing your design.

Tools & Materials Checklist

| Item | Purpose |

|---|---|

| Sanitary tees (PVC or ABS) | Direct flow and prevent scum escape |

| Effluent filter (e.g., Zoeller or Orenco) | Trap suspended solids |

| Butyl rubber gaskets | Waterproof pipe penetrations |

| Laser level or transit | Ensure proper pipe slope |

| Septic tank risers | For easy access during maintenance |

✅ Best Practice: Use Schedule 40 PVC for all internal plumbing—it’s durable, smooth, and code-approved.

How to Read a Septic Tank Plumbing Diagram

A standard diagram includes:

- Top view: Shows lid locations, access points, and compartment division

- Side cross-section: Reveals pipe depths, baffle positions, and liquid levels

- Labels: Inlet, outlet, baffle, filter, and sludge zone

Look for dimension lines indicating:

- Distance from tank bottom to pipe centerline

- Height of liquid surface (typically 48–60″ in a 1,000-gallon tank)

📘 Reference: For foundational knowledge on wastewater systems, see the Wikipedia page on septic tanks, which outlines global design principles and historical context.

FAQ Section

Q1: Can I plumb the inside of a septic tank myself?

A: Yes—but only if you understand local codes and have plumbing experience. Many states require a licensed installer for permits. Mistakes can lead to environmental contamination or fines.

Q2: What’s the ideal depth for inlet and outlet pipes?

A: The inlet should enter 2–3 inches above the outlet. Both should sit 12–18 inches below the tank’s top rim. Exact depths depend on tank size and daily flow (e.g., a 1,500-gallon tank for a 4-bedroom home).

Q3: Do I need an effluent filter?

A: Not federally mandated, but required in 30+ states. Even where optional, experts strongly recommend them—they cost $50–$100 but prevent $5,000+ drain field repairs.

Q4: How often should I inspect internal plumbing?

A: Every time you pump the tank (every 3–5 years). Technicians should check for baffle damage, filter clogs, and pipe corrosion.

Q5: Can I use a single-chamber tank?

A: Older homes may have them, but modern codes require two compartments for better solids retention. Upgrading is often necessary during repairs or resale.

Q6: What happens if the outlet is too high?

A: Scum and floating solids escape into the drain field, causing rapid clogging. This is a leading cause of premature system failure.

Conclusion

Mastering how to plumb the inside of a septic tank diagram isn’t just about pipes and fittings—it’s about protecting your home, your wallet, and the environment. With the right design, your system can last 25–30 years with minimal issues.

✅ Key Takeaways:

- Always use baffles and consider an effluent filter

- Maintain proper elevation between inlet and outlet

- Follow local codes—not just generic online advice

- Document your setup with a clear, labeled diagram

Found this guide helpful? Share it on Facebook, Pinterest, or Reddit to help fellow homeowners avoid costly septic mistakes! And if you’re unsure, consult a certified septic professional—it’s worth the peace of mind.

Leave a Reply