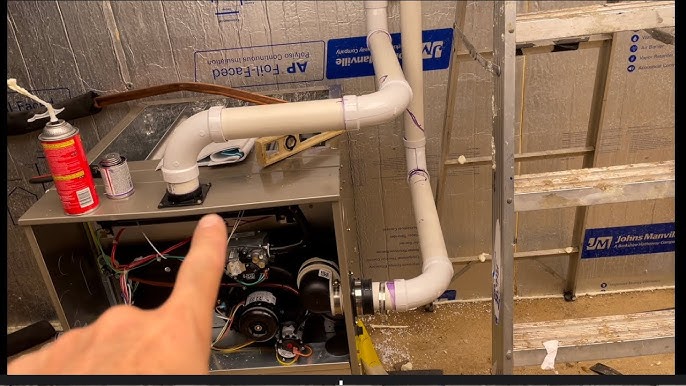

If you’ve recently upgraded to a high-efficiency furnace—or are planning to—you’ve probably heard about PVC venting. Unlike older metal-vented systems, modern condensing furnaces use PVC pipes for both intake and exhaust. But here’s the catch: how to properly plumb the PVC furnace intake and exhaust isn’t just about connecting pipes—it’s critical for safety, performance, and avoiding costly repairs or carbon monoxide risks. In this guide, we’ll walk you through everything you need to know, step by step, with expert-backed advice and real-world best practices.

Why Do High-Efficiency Furnaces Use PVC Pipes?

Traditional furnaces vent hot combustion gases through metal flues. But condensing furnaces (90%+ AFUE) extract so much heat that exhaust gases cool significantly—often below 140°F (60°C). This creates condensation that’s mildly acidic, which would corrode metal vents over time.

That’s why manufacturers specify PVC, CPVC, or ABS plastic piping—they resist corrosion and are cost-effective. According to the U.S. Department of Energy, over 65% of new gas furnaces installed in the U.S. since 2020 are condensing models, making PVC venting increasingly common in residential HVAC systems.

💡 Expert Insight: “Using the wrong pipe material or improper slope can lead to water pooling, blockages, or even dangerous backdrafting,” says HVAC engineer Maria Lopez, certified by NATE (North American Technician Excellence).

For more on combustion types and venting, see Wikipedia’s overview on furnace classifications.

What’s the Difference Between Intake and Exhaust Pipes?

Many homeowners confuse the two—but they serve opposite roles:

| Pipe Type | Function | Airflow Direction | Typical Diameter |

|---|---|---|---|

| Exhaust (Vent) | Carries combustion byproducts out of your home | Furnace → Outside | 2″ or 3″ |

| Intake (Combustion Air) | Brings fresh outdoor air into the furnace for combustion | Outside → Furnace | Same as exhaust |

Both pipes usually run side-by-side through an exterior wall or roof. Never share a single pipe for both functions—this violates building codes and risks incomplete combustion.

Step-by-Step: How to Properly Plumb the PVC Furnace Intake and Exhaust

Follow these steps carefully. Always consult your furnace manual first—manufacturer specs override general guidelines.

Step 1: Check Local Codes & Manufacturer Requirements

- Most jurisdictions follow the International Fuel Gas Code (IFGC) or Uniform Mechanical Code (UMC).

- Confirm allowable pipe material (PVC Schedule 40 is common), max length, and termination clearances.

- Example: Exhaust must be at least 12 inches above grade and 3 feet from windows, doors, or mechanical air intakes.

Step 2: Choose the Right Pipe Size & Material

- Most residential units use 2-inch or 3-inch diameter PVC Schedule 40.

- Never use standard plumbing PVC for exhaust—it may not handle temperature fluctuations. Use HVAC-rated PVC labeled for venting.

- Both intake and exhaust pipes should be the same diameter unless specified otherwise.

Step 3: Maintain Proper Slope

- Exhaust pipe: Slope ¼ inch per foot back toward the furnace to drain condensate into the condensate trap.

- Intake pipe: Slope ¼ inch per foot away from the furnace to prevent rainwater from entering.

- Use a level and measure carefully—improper slope is a top cause of service calls.

Step 4: Install with Correct Termination Clearances

Per IFGC Section 503.8, terminations must meet:

- 3 ft below, 3 ft horizontally, or 1 ft above any window/door.

- 10 ft from mechanical air intakes (like HRVs or ERVs).

- 2 ft above finished grade if vertical termination.

- Use listed termination caps—never leave pipes open-ended.

Step 5: Seal All Joints Properly

- Use PVC primer and cement rated for pressure piping.

- Wipe joints clean, apply primer, then cement, and hold for 30 seconds.

- Test for leaks with a smoke pencil or visual inspection during startup.

Step 6: Support the Pipes Every 3–4 Feet

- Unsupported runs can sag, disrupting slope and drainage.

- Use plastic or non-corrosive metal hangers—avoid direct contact with wood framing without protection.

Common Mistakes to Avoid

Even experienced DIYers make these errors:

- Reversing intake and exhaust pipes – This starves the furnace of oxygen.

- Running exhaust too long or with too many elbows – Max equivalent length is usually 100 feet (including elbows counted as extra length).

- Ignoring condensate drainage – A clogged trap can shut down your furnace via safety switch.

- Using glue not rated for HVAC – Standard plumbing cement may fail under thermal cycling.

📊 Stat Alert: A 2024 study by the National Comfort Institute found that 42% of improperly vented furnaces showed elevated CO levels during operation—most due to reversed pipes or poor slope.

PVC vs. Metal Venting: Which Is Better?

| Feature | PVC Venting | Metal Venting |

|---|---|---|

| Best For | High-efficiency (condensing) furnaces | Mid-efficiency (80% AFUE) |

| Corrosion Resistance | ✅ Excellent | ❌ Poor (with condensation) |

| Cost | Low ($1–$2/ft) | High ($5–$10/ft) |

| Installation Ease | Easy (lightweight, glue joints) | Harder (requires welding/sealing) |

| Max Temp Tolerance | ~140°F | 400°F+ |

Verdict: If you have a 90%+ AFUE furnace, PVC is required—not optional.

FAQ Section

Q1: Can I use the same PVC pipe for both intake and exhaust?

No. While the pipes look identical, they serve separate functions. Sharing one pipe compromises combustion air supply and risks carbon monoxide buildup.

Q2: How far can I run the PVC vent pipes?

Most manufacturers allow up to 100 equivalent feet. Each 90° elbow adds ~5 ft of resistance; 45° adds ~2.5 ft. Always check your unit’s installation manual.

Q3: Should the exhaust pipe go through the roof or wall?

Both are acceptable if code-compliant. Wall terminations are easier and cheaper. Roof runs require proper flashing and support but avoid snow-blockage risks in cold climates.

Q4: Why is my furnace leaking water near the PVC pipes?

Likely causes: incorrect slope (water pooling), cracked pipe, or clogged condensate drain. Inspect the exhaust slope and condensate trap immediately.

Q5: Can I paint PVC vent pipes to match my house?

Yes—but only with paint rated for exterior PVC. Avoid oil-based paints; they can degrade the plastic over time.

Q6: Do I need a permit to install PVC furnace vents?

In most U.S. municipalities, yes. HVAC modifications typically require inspection to ensure compliance with gas and mechanical codes.

Conclusion

Knowing how to properly plumb the PVC furnace intake and exhaust isn’t just a technical skill—it’s a safety essential. When done right, your system will run efficiently, last longer, and keep your family safe from harmful gases. Always prioritize manufacturer instructions, local codes, and proper slope over speed or cost-cutting.

✅ Key Takeaways:

- Use HVAC-rated PVC, correct diameter, and proper slope.

- Keep intake and exhaust separate with code-compliant terminations.

- Support pipes every 3–4 feet and seal all joints.

- When in doubt, hire a licensed HVAC technician.

Found this guide helpful? Share it on Facebook, Pinterest, or Twitter to help other homeowners stay warm—and safe—this winter! ❄️🔥

Leave a Reply