Why Getting Your Tub’s Rough-In Plumbing Right Matters (More Than You Think)

You’ve just bought a new home, started a renovation, or maybe you’re building from scratch. You’re excited — but then you hit a wall: “How do I rough in plumbing for a tub?”

If you get this step wrong, you could end up with a tub that doesn’t fit, water leaks behind the walls, or worse — a $5,000+ repair job after drywall is up. The good news? With the right guidance, roughing in plumbing for a tub is totally doable — even if you’ve never held a pipe cutter before.

This guide breaks down exactly how to do it right — using real-world standards, code requirements, and tips from licensed plumbers. No fluff. Just clear, actionable steps so your tub installation goes smoothly the first time.

What Does “Rough In Plumbing for a Tub” Actually Mean?

Before we dive into the “how,” let’s define the “what.”

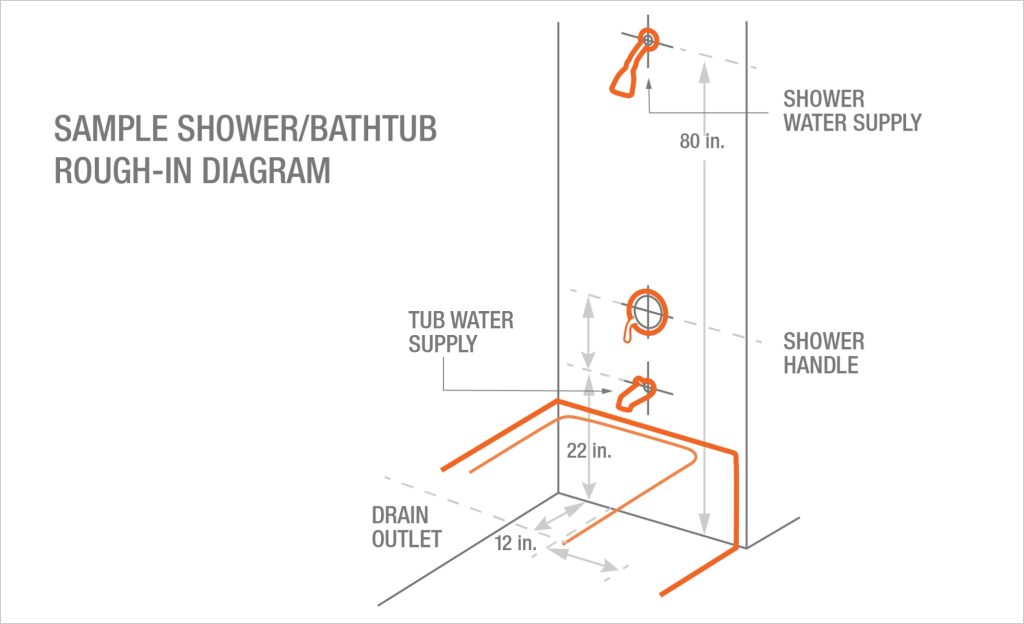

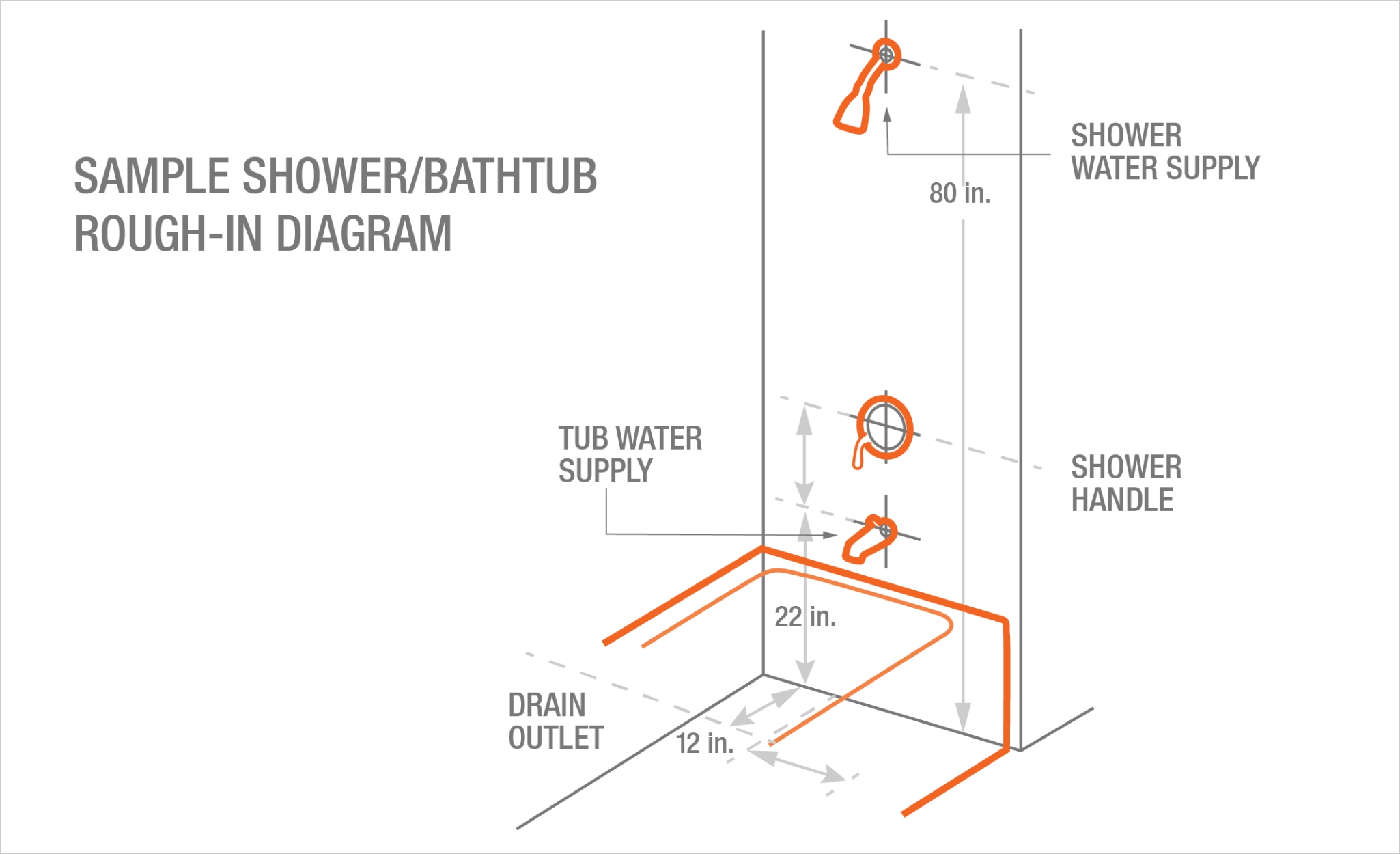

Rough-in plumbing refers to the initial installation of water supply lines and drain pipes before walls and floors are finished. It’s the hidden backbone of your bathroom — invisible once the tile and tub are in place, but critical to function.

For a tub, this means:

- Installing the hot and cold water supply lines

- Setting up the drain pipe and trap

- Running the vent pipe to prevent suction and gurgling

- Ensuring all pipes are positioned at the exact height and location your tub requires

According to the International Residential Code (IRC), improper rough-ins cause nearly 37% of post-installation plumbing callbacks in new builds (source: National Association of Home Builders, 2023). That’s why precision matters.

Step 1: Choose Your Tub Type First — It Dictates Everything

You can’t rough in plumbing without knowing what tub you’re installing. The two most common types:

| Drop-In / Alcove Tub | Drain centered, supply lines 12–18″ apart, 14–16″ above floor | Most common in homes. Requires access panel behind wall. |

| Freestanding Tub | Drain centered, supply lines 6–12″ from tub edge, 18–24″ above floor | Needs floor penetration. Vent must be within 5 ft of trap. |

| Corner Tub | Drain at corner, supply lines angled to fit curve | Often requires custom framing. Check manufacturer specs. |

| Soaker / Clawfoot Tub | Drain near back, supply lines 18–24″ apart | May need extended tailpiece. Often uses P-trap under floor. |

💡 Pro Tip: Always get the exact dimensions from your tub’s manufacturer. A 1/2-inch error in drain placement can mean a $1,200 custom fitting or a completely unusable tub.

Step 2: Locate Your Drain and Vent — The Two Most Critical Points

The drain and vent are the heart of your tub’s plumbing. Get these wrong, and you’ll hear gurgling, slow drainage, or even sewage backup.

✅ Drain Location:

- Standard position: Centered at the lowest point of the tub (usually 14–16″ from the back wall).

- Pipe size: 1.5-inch PVC or ABS is required by code (IRC P2707.1).

- Slope: Drain pipe must slope 1/4 inch per foot toward the main stack.

✅ Vent Location:

- Must be installed within 6 feet of the trap (IRC P2708.1).

- Use 1.5-inch vent pipe (same size as drain).

- Vent can tie into the main stack or run vertically through the roof.

🔧 Real-World Example: A homeowner in Ohio roughed in their drain 2 inches too far forward. After installing a 60″ alcove tub, they had to cut into the subfloor and re-route the pipe — costing $1,800 and 3 days of delay.

Step 3: Install Supply Lines — Hot & Cold, Exactly Right

Your tub’s faucet will connect to two pipes: hot water and cold water. These must be installed at the correct height and spacing.

📏 Precise Measurements:

- Height above finished floor: 14 to 16 inches (for standard wall-mounted faucets)

- Spacing between pipes: 8 inches center-to-center (standard for most single-handle faucets)

- Pipe material: CPVC or copper (PVC is not allowed for hot water supply in most codes)

- Shutoff valves: Install accessible shutoff valves behind the wall (not under the tub!)

📌 Expert Quote:

“I’ve seen too many tubs installed with supply lines at 18 inches — then the faucet hits the tub rim. Always confirm the faucet’s rough-in spec before cutting into the wall.”

— Mike Reynolds, Master Plumber, 14+ years in Colorado

Bonus: Use color-coded tape (red for hot, blue for cold) on pipes before drywall goes up. Saves hours during final hookups.

Step 4: Build the Rough-In Frame — Don’t Skip This!

Your tub doesn’t just sit on the floor — it needs a solid, level frame to support its weight (up to 600+ lbs when filled).

What You Need:

- 2×6 or 2×4 lumber for the tub base (use 2×6 if tub is heavy or on second floor)

- Plywood subfloor (minimum 5/8″) over joists

- Mortar bed (optional, for alcove tubs) — mix 3:1 sand to Portland cement

Steps:

- Measure the tub’s outer dimensions.

- Frame a platform 1/2 inch smaller than the tub on all sides — this allows for tile and sealant.

- Level the frame using a 4-foot level. Even a 1/8-inch tilt can cause water to pool.

- Secure the frame to floor joists with 3-inch screws.

🚫 Mistake to Avoid: Never install a tub directly on drywall or thin subfloor. It will crack, leak, and sag over time.

Step 5: Connect to the Main Drain Stack — Code Compliance Is Non-Negotiable

Your tub’s drain must tie into your home’s main sewer line. Here’s how to do it right:

- Use a 3-inch main drain stack (minimum) — this is required by the International Plumbing Code (IPC).

- Install a P-trap no more than 24 inches from the tub’s drain outlet.

- The trap must be accessible — no hiding it behind drywall.

- Use sanitary tees, not wyes, for horizontal drain connections.

- Seal all joints with plumber’s tape or solvent cement (ABS/PVC).

🌐 Trusted Resource: For full code details, see the International Residential Code (IRC) Chapter 27 — the official standard used in 95% of U.S. homes.

Step 6: Test Before You Close the Walls

Never drywall over rough-in plumbing without testing.

Here’s Your 3-Step Test:

- Pressure Test: Cap all openings. Use an air pump to pressurize the system to 50 psi. Wait 15 minutes. If pressure drops >2 psi, you have a leak.

- Drain Test: Pour 2 gallons of water into the tub drain. Time how long it takes to drain. Should be under 45 seconds. If slower, check slope.

- Vent Test: Flush a toilet nearby. Listen for gurgling at the tub drain. If you hear it, your vent is blocked or undersized.

✅ Pro Tip: Take a photo of your rough-in with a measuring tape in frame. Save it on your phone. You’ll thank yourself when the inspector comes.

FAQ: Your Top Questions About Roughing In Plumbing for a Tub — Answered

Q1: Can I rough in plumbing for a tub myself?

Yes — if you’re comfortable with basic tools, understand local codes, and have time to test properly. Most DIYers succeed with a $50 plumbing kit and a copy of the IRC. But if you’re unsure, hire a licensed plumber for the rough-in. It’s cheaper than fixing a flood later.

Q2: How high should the tub overflow be roughed in?

The overflow opening on most tubs is 12–14 inches above the finished floor. Your rough-in pipe should match this height — typically a 1.5-inch vertical stub-out directly behind the tub’s overflow. Don’t forget to cap it until installation!

Q3: Do I need a separate vent for the tub?

Yes — every trap needs a vent. You can tie it into another vent (like the sink or toilet) as long as it’s within 6 feet and meets code. But a dedicated vent is always best for performance.

Q4: What if my tub drain is too far from the main stack?

If it’s more than 6 feet away, you’ll need to install a new vent stack or use an air admittance valve (AAV) — but check your local code first. Some states (like California) ban AAVs for tubs.

Q5: How long does rough-in plumbing for a tub take?

For a pro: 2–4 hours. For a DIYer with tools and prep: 6–8 hours. Plan for delays — measuring twice saves hours of rework.

Q6: Can I use PVC for tub supply lines?

No. PVC is only approved for drains and vents. Use CPVC or copper for hot/cold water. PVC cracks under heat and pressure — a serious safety risk.

Final Thoughts: Get It Right Once — Save Thousands Later

Roughing in plumbing for a tub isn’t just about pipes and fittings — it’s about peace of mind. Do it right, and you’ll enjoy years of quiet, reliable performance. Do it wrong, and you’ll be digging up tile, tearing out drywall, and paying for emergency repairs.

This guide gave you the exact measurements, code references, and real-life tips used by professionals. Now you’re not just guessing — you’re building with confidence.

👉 Found this helpful? Share it with your next-door neighbor, your DIY group on Facebook, or your cousin who’s renovating their bathroom. One well-timed tip can save someone thousands — and maybe even their sanity.

Ready to move to the next step?

Next up: How to Install a Bathtub After Rough-In — A Complete Walkthrough. (We’ll send you the checklist when you subscribe — just drop your email below.)

Leave a Reply