If you’ve noticed mysterious pinhole leaks, discolored water, or premature pipe failure in your home, you’re not alone. Many homeowners struggle to pinpoint whether galvanic corrosion or erosion corrosion is eating away at their plumbing system. The confusion is understandable—both types of corrosion can look similar but stem from very different causes and require distinct solutions. In this guide, we’ll break down exactly what each type is, how to tell them apart, and most importantly, how to protect your home’s plumbing for years to come.

What Is Galvanic Corrosion in Plumbing?

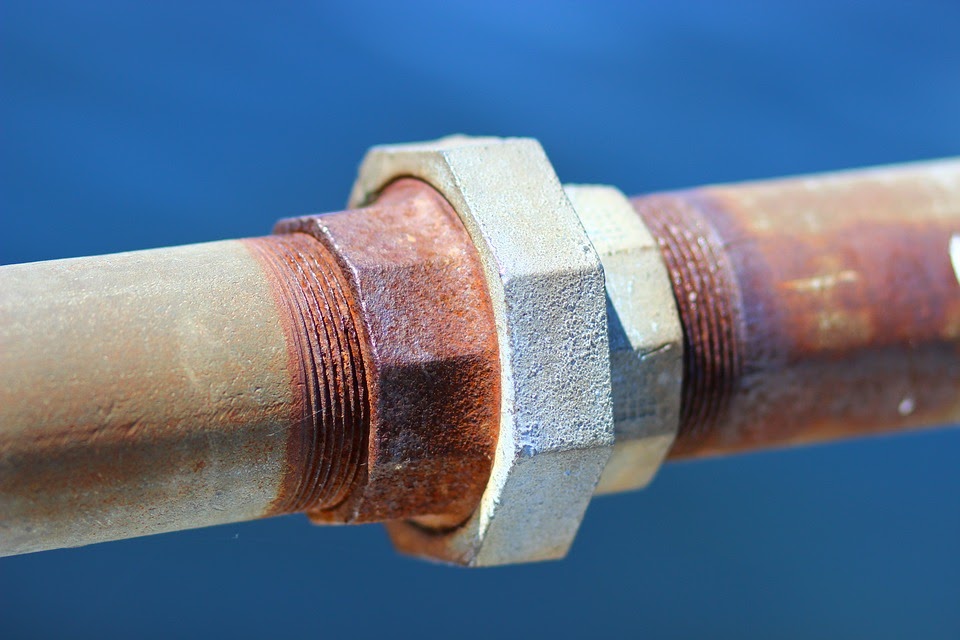

Galvanic corrosion occurs when two dissimilar metals are in direct contact while immersed in an electrolyte—like water. This creates a small electrical current that accelerates the corrosion of the less noble (more anodic) metal.

For example, connecting copper pipes directly to steel or galvanized iron pipes without a dielectric union is a classic recipe for galvanic corrosion. Over time, the steel pipe will corrode rapidly, leading to leaks or even complete pipe failure.

Real-World Example: A 2021 study by the National Association of Home Builders (NAHB) found that nearly 23% of premature plumbing failures in homes built between 1980–2005 were linked to improper metal-to-metal connections—a hallmark of galvanic corrosion.

You can learn more about the electrochemical principles behind this process on Wikipedia’s page on galvanic corrosion.

What Is Erosion Corrosion in Plumbing?

Unlike galvanic corrosion, erosion corrosion isn’t caused by metal compatibility—it’s driven by high-velocity water flow, turbulence, or suspended particles in the water. When water rushes through pipes at excessive speeds (typically above 8–10 feet per second), it wears away the protective oxide layer inside copper pipes, exposing fresh metal to further degradation.

This often appears as smooth, horseshoe-shaped pits near elbows, tees, or valves—areas where water changes direction abruptly.

Expert Insight: According to the Copper Development Association (CDA), erosion corrosion is most common in:

- Homes with high water pressure (>80 psi)

- Systems using recirculating hot water loops

- Areas with hard or aggressive water (low pH, high oxygen)

Galvanic vs. Erosion Corrosion: Key Differences

| Feature | Galvanic Corrosion | Erosion Corrosion |

|---|---|---|

| Cause | Contact between dissimilar metals + electrolyte (water) | High water velocity, turbulence, or abrasive particles |

| Location | At joints between different metals (e.g., copper + steel) | Near bends, elbows, valves, or pumps |

| Appearance | Localized pitting, often with white/green deposits | Smooth, washed-out grooves or pits; shiny surface |

| Pipe Material Affected | Anodic metal (e.g., galvanized steel, aluminum) | Primarily copper pipes |

| Prevention | Use dielectric unions or non-conductive fittings | Reduce water velocity, install flow straighteners |

How to Identify Which Type You Have

Follow these steps to diagnose the issue:

- Inspect the Leak Location

- If the leak is right at a joint between copper and galvanized pipe → suspect galvanic corrosion.

- If the leak is on a straight section or bend in a copper line with no metal mixing → likely erosion corrosion.

- Check Water Pressure

Use a pressure gauge on an outdoor spigot. If it reads above 80 psi, erosion corrosion is probable. Ideal household pressure is 40–60 psi. - Look for Telltale Signs

- Galvanic: Rust stains, flaking, or rapid deterioration of one pipe type near a connection.

- Erosion: Polished, almost “scooped-out” areas inside copper pipes; no rust, but possible blue-green staining from copper leaching.

- Review Your Plumbing History

Did a recent renovation mix pipe materials? That’s a red flag for galvanic issues.

How to Prevent & Fix Galvanic Corrosion

✅ Step 1: Install Dielectric Unions

Always use a dielectric union (a non-conductive fitting made of plastic or rubber-lined brass) when connecting copper to steel or galvanized pipes. This breaks the electrical circuit.

✅ Step 2: Replace Mixed-Metal Sections

If your system already has direct metal-to-metal contact, replace the affected section with uniform piping (e.g., all PEX or all copper) or insert dielectric fittings.

✅ Step 3: Test Your Water’s Conductivity

Highly conductive water (due to dissolved salts or minerals) worsens galvanic corrosion. A simple TDS (Total Dissolved Solids) meter can help assess risk.

💡 Pro Tip: In coastal areas or homes with softened water, galvanic corrosion accelerates due to higher ion concentration. Consider whole-house water treatment if needed.

How to Prevent & Fix Erosion Corrosion

✅ Step 1: Reduce Water Velocity

Install a pressure-reducing valve (PRV) if your home’s pressure exceeds 60 psi. Aim for 5–7 feet per second flow in copper lines.

✅ Step 2: Redesign Problematic Layouts

Avoid sharp 90-degree elbows. Use long-sweep elbows or gentle bends to minimize turbulence.

✅ Step 3: Flush Air from Lines

Air pockets combined with fast-moving water create cavitation, which accelerates erosion. Bleed air from your system after repairs or new installations.

✅ Step 4: Upgrade Pipe Diameter

If your home uses undersized pipes (e.g., ½-inch for main lines), consider upgrading to ¾-inch to lower flow velocity.

📊 Stat Alert: The EPA estimates that 10% of U.S. homes have water pressure above 80 psi—putting them at elevated risk for erosion corrosion in copper systems.

FAQ Section

Q1: Can galvanic and erosion corrosion happen at the same time?

A: Yes. A poorly designed system might have mixed metals and high water velocity, leading to both issues simultaneously—especially in older homes with multiple renovations.

Q2: Does PEX plumbing eliminate these corrosion risks?

A: Absolutely. PEX (cross-linked polyethylene) is non-metallic, so it’s immune to both galvanic and erosion corrosion. It’s a popular choice for repiping projects.

Q3: How long does it take for galvanic corrosion to cause a leak?

A: It varies. In aggressive water conditions, leaks can appear in as little as 6–12 months after improper installation. In milder cases, it may take 5–10 years.

Q4: Is erosion corrosion covered by homeowner’s insurance?

A: Often not. Most policies exclude “gradual wear and tear,” which includes corrosion. Prevention is far cheaper than repair.

Q5: Can I test for these types of corrosion myself?

A: You can spot visual clues (see identification steps above), but a licensed plumber can perform pipe camera inspections or water chemistry tests for definitive diagnosis.

Q6: Are certain regions more prone to these issues?

A: Yes. Homes in soft-water areas (low mineral content) face higher erosion corrosion risk because soft water is more aggressive to copper. Meanwhile, coastal or high-mineral areas increase galvanic corrosion potential.

Conclusion

Understanding whether your household plumbing is suffering from galvanic corrosion or erosion corrosion isn’t just academic—it’s essential for preventing costly water damage and ensuring your system lasts decades. By identifying the root cause, using the right materials, and maintaining proper water pressure, you can protect your home’s integrity and avoid emergency repairs.

👉 Found this guide helpful? Share it with a friend or on social media! A quick share could save someone thousands in plumbing bills—and maybe even prevent a basement flood.

Your pipes work hard for you. Return the favor with smart, informed care.

Leave a Reply