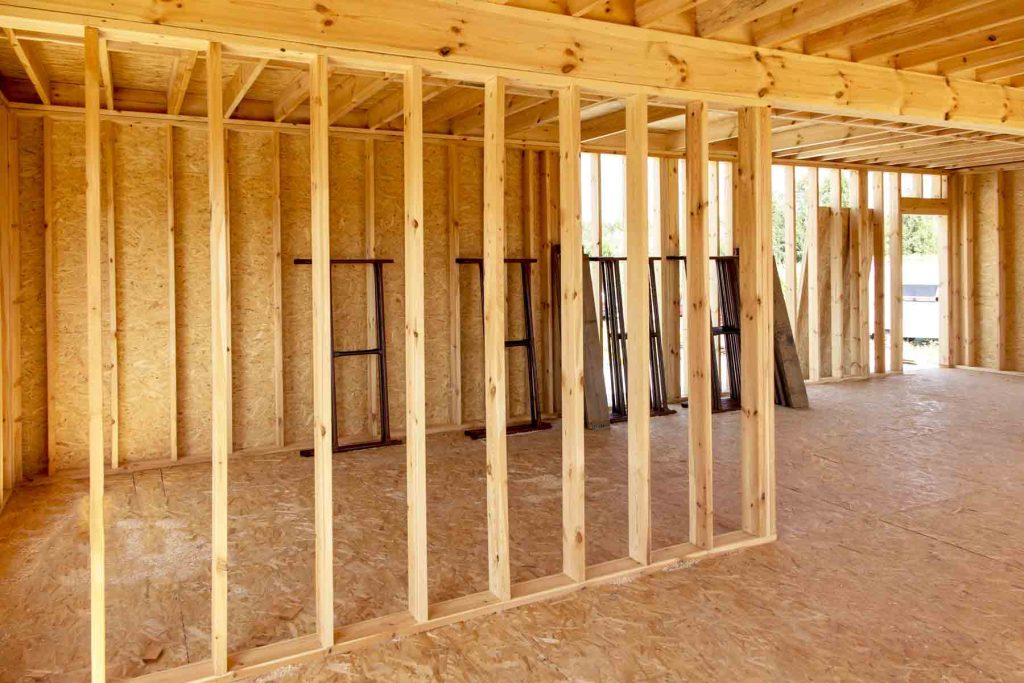

If you’ve ever watched a home being framed or peeked behind drywall during a renovation, you might have noticed wood blocks tucked into wall cavities—especially near corners. But are these blocks actually required or even used specifically for electrical or plumbing installations in framing corners? It’s a common point of confusion for DIYers, contractors, and even new builders. In this guide, we’ll clarify exactly when—and why—blocking appears in corners, and whether it serves a purpose for running wires or pipes.

What Is Blocking in Wall Framing?

In residential construction, blocking (also called “fire blocking” or “bridging”) refers to short pieces of lumber installed horizontally between studs or vertically between joists. Its primary purposes include:

- Providing structural support for drywall edges

- Preventing fire spread through concealed cavities (fire blocking)

- Offering nailing surfaces for cabinets, trim, or fixtures

- Stabilizing wall framing against twisting or buckling

According to the International Residential Code (IRC), fire blocking is required in specific locations—including at ceiling and floor levels, and at changes in framing direction, such as corners.

🔍 Key Insight: While blocking isn’t primarily installed for electrical or plumbing access, its presence can significantly impact how (and where) you run those systems.

Are Corners Common Locations for Blocking?

Yes—corners almost always contain blocking, but not because of electrical or plumbing needs.

When two walls meet at a 90-degree angle (an “L-corner”), framers typically use one of two methods:

- California Corner (or “Three-Stud Corner”) – Uses three full studs with a small filler block.

- Advanced Framing (Optimum Value Engineering) – Uses only two studs plus a backing block for drywall.

In both cases, a solid wood block is installed at the interior corner to provide a nailing surface for drywall on both walls. This block runs from top plate to bottom plate and fills the cavity.

📌 Important: This blocking occupies the entire depth of the corner cavity—leaving zero space for running electrical cables or plumbing pipes through that exact spot.

According to a 2023 study by the National Association of Home Builders (NAHB), over 85% of new U.S. homes use some form of corner blocking, primarily for drywall support—not utility access.

Can You Run Electrical or Plumbing Through Framing Corners?

Technically, yes—but it’s strongly discouraged and often impractical.

Here’s why:

| Issue | Electrical | Plumbing |

|---|---|---|

| Space | Corner blocking leaves no cavity | Same—solid wood fills the gap |

| Code Compliance | NEC allows wiring in walls, but not through solid blocking without drilling | IPC prohibits running supply lines through fire-blocked zones without protection |

| Practicality | Drilling through corner blocks weakens structure | Risk of leaks near seams; hard to access later |

| Best Practice | Run wires 6–12 inches away from corner | Keep pipes in open stud bays, not corners |

💡 Pro Tip: Electricians and plumbers are trained to avoid corners entirely. Instead, they route conduits and pipes through the center of adjacent stud bays, where there’s ample space and no blocking.

For example:

- Electrical outlets near corners are typically placed 4–6 inches from the corner edge, not right at the seam.

- Plumbing vents or supply lines are offset by at least one full stud bay (16″ or 24″ on center).

When Is Blocking Added Specifically for Utilities?

While standard corner blocking isn’t for utilities, additional blocking may be installed later to support them:

- Electrical: A horizontal block might be added behind a future TV mount or light fixture to secure a junction box.

- Plumbing: In bathrooms, blocking is often installed between studs to support grab bars or heavy fixtures like wall-mounted toilets.

However, this is custom blocking, not part of the original corner framing—and it’s placed where needed, not automatically in every corner.

📚 Source: The U.S. Department of Energy’s Advanced Framing Guidelines recommend minimizing unnecessary blocking to reduce material costs and improve insulation—further confirming that utility-driven blocking is situational, not standard.

Step-by-Step: How to Safely Install Wiring Near a Framed Corner

If you must run electrical near a corner (e.g., for an outlet), follow these steps:

- Locate the corner block: Use a stud finder to identify the solid wood section (usually 3.5″ wide at the interior corner).

- Measure 6 inches away: Mark a point on the adjacent wall, 6 inches from the corner.

- Drill through the stud: Use a ¾” spade bit to drill a hole 1¼ inches from the edge of the stud (per NEC 300.4 for nail protection).

- Install protective plates: If the hole is closer than 1¼” to the edge, add a steel nail plate to prevent accidental punctures.

- Run NM cable (Romex): Feed 14/2 or 12/2 cable through the hole, leaving 8″ of slack at the box location.

- Mount the box: Use a remodeling box or nail-on box secured to a custom block if needed.

✅ Safety Note: Never notch or drill the corner post itself—it’s a critical structural element.

Fire Blocking vs. Utility Blocking: Know the Difference

It’s easy to confuse general fire blocking with utility-specific supports. Here’s a quick comparison:

| Feature | Fire Blocking | Utility Blocking |

|---|---|---|

| Purpose | Stop flame/smoke spread | Support fixtures or boxes |

| Location | Corners, soffits, floor transitions | Behind outlets, shelves, grab bars |

| Required by Code? | Yes (IRC R602.8) | No—unless supporting a load |

| Material | Lumber, drywall, foam | Usually same as framing lumber |

| Impact on Utilities | Blocks paths | Enables safe mounting |

Understanding this distinction helps avoid costly rework during inspections.

FAQ Section

Q1: Do building codes require blocking in wall corners?

A: Yes—but for fire safety and drywall support, not for electrical or plumbing. IRC Section R602.8 mandates fire blocking at framing intersections, including corners.

Q2: Can I drill through corner blocking for an electrical outlet?

A: It’s possible but not recommended. Drilling compromises structural integrity and fire containment. Instead, offset the outlet by 6+ inches.

Q3: Why do some corners have extra wood inside?

A: That’s likely either a California corner design (for drywall backing) or advanced framing with a single backing block. Neither is meant for running pipes or wires.

Q4: Does plumbing ever go through corners?

A: Rarely. Supply and drain lines avoid corners due to lack of space and access. Vents may pass near corners but are routed through open bays.

Q5: What if I already ran wire through a corner block?

A: Have a licensed electrician inspect it. If the hole is small (<1″ diameter) and reinforced, it may pass inspection—but it’s not best practice.

Q6: How can I find blocking behind drywall?

A: Use a high-quality stud finder with deep-scan mode, or tap along the wall—solid thuds indicate blocking. Thermal cameras can also detect temperature differences.

Conclusion

So, is blocking used on framing corners for electrical or plumbing? The short answer: No—it’s there for structure and fire safety, not utilities. While you can modify it, doing so risks code violations, reduced fire resistance, and future repair headaches.

Smart builders and tradespeople work around corner blocking, not through it. By understanding framing best practices, you’ll save time, pass inspections smoothly, and build safer, more efficient homes.

🔧 Found this helpful? Share it with your contractor, DIY group, or on social media! A little knowledge goes a long way in avoiding costly mistakes behind the walls.

Leave a Reply