If you’ve ever watched a plumber work or tried a DIY plumbing project yourself, you’ve probably wondered: Is it necessary to have pipes perfectly aligned when plumbing? Misaligned pipes can look messy—but more importantly, they might lead to leaks, reduced water pressure, or even code violations. In this guide, we’ll break down exactly how critical perfect alignment really is, when minor deviations are acceptable, and what professionals do to ensure long-lasting, efficient plumbing systems.

Why Pipe Alignment Matters in Plumbing Systems

Proper pipe alignment isn’t just about aesthetics—it directly impacts functionality, durability, and compliance with plumbing codes. According to the International Plumbing Code (IPC), pipes must be installed to allow for proper drainage, minimize stress on joints, and prevent blockages.

Misalignment can cause:

- Leaks at joints due to uneven pressure distribution

- Reduced flow efficiency, especially in drain-waste-vent (DWV) systems

- Premature wear on fittings and seals

- Failed inspections during home sales or renovations

While “perfect” alignment may sound ideal, real-world installations often involve slight offsets due to framing, existing structures, or material tolerances. The key is understanding how much deviation is acceptable—and when it crosses into risky territory.

What Does “Perfect Alignment” Really Mean?

In plumbing, “perfect alignment” typically refers to pipes that are coaxial—meaning their centerlines match up straight through connected fittings. However, industry standards recognize that minor angular or lateral offsets are common and often unavoidable.

For example:

- PVC and ABS pipes: Allow up to 2–3 degrees of angular misalignment per joint without compromising seal integrity (per ASTM D2665/D2751 standards).

- Copper tubing: Requires tighter tolerances; even a 1/8-inch offset can strain soldered joints over time.

- Cast iron (older systems): Tolerates more variation but relies heavily on proper hub-and-spigot sealing.

💡 Expert Insight: “In 15 years of residential plumbing, I’ve rarely seen ‘perfect’ alignment—but I’ve fixed dozens of leaks caused by excessive misalignment,” says Marcus Lee, Master Plumber and IPC-certified inspector.

When Is Slight Misalignment Acceptable?

Not every pipe run needs laser-straight precision. Here’s when minor misalignment is generally safe and code-compliant:

✅ Using flexible couplings or no-hub connectors (common in cast iron or PVC repairs)

✅ Installing offset fittings like street elbows or bends designed to redirect flow

✅ Working around obstacles (e.g., studs, ductwork) with approved offsets

✅ Drain lines with proper slope (¼ inch per foot)—as long as water flows freely

However, never force-fit rigid pipes to “make them meet.” This creates internal stress that can crack fittings or loosen joints over time.

Risks of Poor Pipe Alignment: Real-World Consequences

A 2023 study by the National Association of Home Builders (NAHB) found that 12% of plumbing-related callbacks were due to joint failures linked to misalignment. Common issues include:

| Problem | Cause | Long-Term Impact |

|---|---|---|

| Slow leaks under sinks | Slightly angled P-trap connections | Water damage, mold growth |

| Gurgling drains | Misaligned vent stacks | Sewer gas infiltration |

| Cracked PVC joints | Forced alignment during glue-up | Full system failure within 1–2 years |

One documented case in Austin, TX involved a new-build home where plumbers crammed DWV pipes into a tight wall cavity without proper offsets. Within six months, three separate leaks developed—all traced to stressed, misaligned joints.

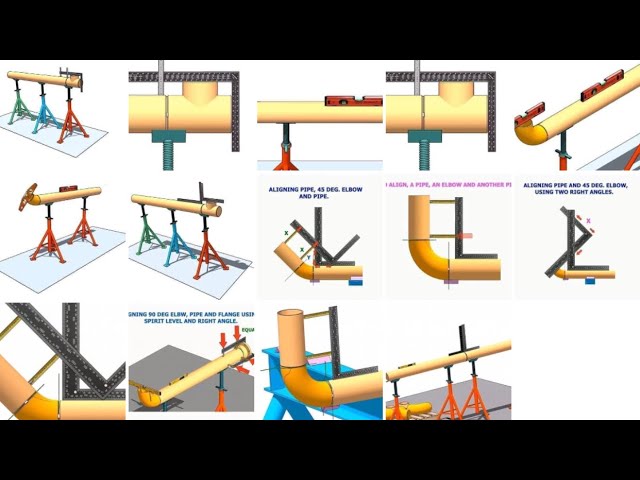

Best Practices for Proper Pipe Alignment (Step-by-Step)

Whether you’re a DIYer or hiring a pro, follow these steps to ensure safe, durable alignment:

- Dry-fit all components first

Assemble pipes and fittings without glue or solder to check alignment. Use a laser level or straightedge for long runs. - Use appropriate fittings—not brute force

Need a slight angle? Use a 22.5° or 45° elbow, not by bending the pipe. - Maintain consistent slope for drains

Horizontal drain pipes must slope ¼ inch per foot toward the main stack. Use a bubble level with slope indicator. - Support pipes every 4 feet (for PVC)

Proper hangers reduce sagging that causes misalignment over time. - Inspect joints before finalizing

For solvent-weld PVC: Ensure pipe bottoms out fully in the fitting socket. Gap = weak joint. - Pressure-test the system

After installation, test with 60 PSI air or water for 15 minutes (per IPC §312). Any drop indicates a leak—often from poor alignment.

🔗 Learn more about plumbing materials and standards on Wikipedia’s Plumbing page.

Pipe Alignment by Material: What’s Tolerable?

Different materials handle misalignment differently. Here’s a quick comparison:

| Material | Max Angular Offset | Max Lateral Offset | Notes |

|---|---|---|---|

| PVC (Schedule 40) | 2–3° per joint | 1/16″ | Use primer + cement; never dry-fit permanently |

| Copper (Type M/L) | <1° | 1/32″ | Requires precise cutting; use tube benders if needed |

| PEX | Flexible—no strict limit | N/A | Use proper crimp/clamp rings; avoid sharp bends |

| Cast Iron | 3–5° with no-hub couplings | 1/8″ | Older systems tolerate more—but inspect seals |

Key takeaway: Rigid materials (copper, PVC) demand more precision. Flexible systems (PEX) forgive more—but still require correct support.

FAQ Section

Q1: Can slightly misaligned pipes cause low water pressure?

A: Yes—if misalignment creates a partial blockage or restricts flow (e.g., a kinked PEX line or offset reducing coupling). However, minor angular offsets in supply lines rarely affect pressure unless severe.

Q2: Do building inspectors check pipe alignment?

A: Absolutely. Inspectors verify that pipes are properly supported, sloped (for drains), and free of stress-induced gaps. Misaligned joints that appear forced will likely fail inspection.

Q3: Is it okay to use tape or sealant to fix a misaligned joint?

A: Never. Thread seal tape (Teflon) is only for threaded connections—not to compensate for gaps in glued or compression fittings. Doing so creates a false seal that fails under pressure.

Q4: How can I tell if my pipes are misaligned?

A: Look for:

- Visible gaps at joints

- Pipes that “pull” away from walls or supports

- Leaks near connections

- Unusual noises (gurgling, hammering)

Q5: Can I realign pipes myself?

A: Simple drain adjustments (like reseating a P-trap) are DIY-friendly. But for pressurized lines or main stacks, hire a licensed plumber—improper realignment can worsen stress fractures.

Q6: Does pipe alignment affect home resale value?

A: Indirectly, yes. Failed plumbing inspections due to poor workmanship (including misalignment) can delay sales or require costly corrections—lowering buyer confidence.

Conclusion

So, is it necessary to have pipes perfectly aligned when plumbing? While absolute perfection isn’t always practical, precision within industry tolerances is non-negotiable for safety, efficiency, and code compliance. Minor offsets are acceptable when handled with proper fittings and techniques—but forcing pipes together is a recipe for leaks and expensive repairs.

By following best practices and understanding your pipe material’s limits, you’ll ensure a system that lasts decades without issues. If you found this guide helpful, share it with fellow homeowners or DIYers on Facebook, Pinterest, or Reddit—because good plumbing knowledge should flow freely! 💧🔧

Leave a Reply