Have you ever noticed a faint, unpleasant odor lingering around your roofline or wondered why your drains seem to gurgle after a heavy rain? These are often telltale signs that your plumbing ventilation system isn’t spaced correctly, potentially violating safety codes and compromising your home’s air quality. Getting the minimum distance for a plumbing vent from a roof vent right is not just a bureaucratic checkbox; it is a critical safety measure that prevents dangerous sewer gases from entering your living space and ensures your drainage system flows smoothly. In this guide, we will break down the complex building codes into simple, actionable steps so you can ensure your home is safe, compliant, and efficient.

Why Spacing Matters: The Science of Airflow and Safety

Before diving into the specific measurements, it is essential to understand why these distances exist. Plumbing vents, often called “stack vents,” serve two primary purposes: they allow sewer gases to escape safely into the atmosphere and they let fresh air into the drainage system to maintain proper atmospheric pressure. Without this balance, water traps in your sinks and toilets can be siphoned dry, allowing toxic methane and hydrogen sulfide gases to seep into your home.

When a plumbing vent is placed too close to a roof vent (such as an attic soffit vent, ridge vent, or HVAC exhaust), there is a high risk of cross-contamination. Wind patterns can easily blow the expelled sewer gases directly back into your home’s fresh air intake. Furthermore, local building codes, which are largely based on the International Plumbing Code (IPC) and the Uniform Plumbing Code (UPC), mandate specific separations to mitigate this risk. Ignoring these rules can lead to failed inspections, costly rework, and significant health hazards for your family.

What Is the Standard Minimum Distance Requirement?

The most common question homeowners and DIY enthusiasts ask is: “Exactly how many feet do I need?” While local amendments can vary slightly depending on your city or state, the national standards provide a clear baseline that serves as the gold rule for safety.

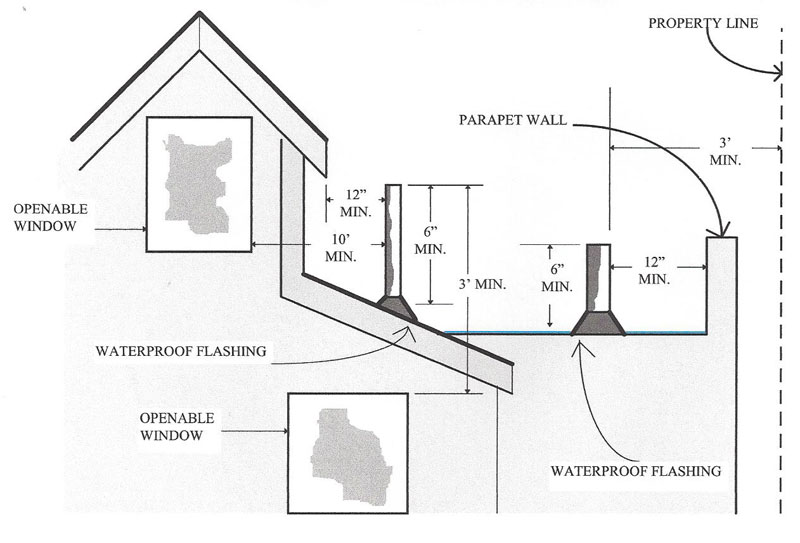

According to the International Plumbing Code (IPC), which is adopted by most states in the US, a plumbing vent terminal must extend at least 10 feet (3048 mm) horizontally from any openable window, door, scuttle, air shaft, or other ventilation opening. This includes roof vents used for attic ventilation or HVAC systems.

Key Distance Metrics at a Glance

| Component Type | Minimum Horizontal Distance | Regulatory Basis |

|---|---|---|

| Openable Windows/Doors | 10 feet (3 meters) | IPC Section 905.5 |

| Non-Openable Windows | Varies (often 4 feet) | Local Amendments |

| Attic/Ridge Vents | 10 feet (3 meters) | IPC Section 905.5 |

| HVAC Intake Vents | 10 feet (3 meters) | IMC & IPC Coordination |

| Property Line | Varies (Check locally) | Zoning Laws |

It is crucial to note that this distance is measured horizontally, not diagonally through the air. If your plumbing vent is lower than the roof vent, the risk of gas infiltration increases, making the 10-foot rule even more critical. Some stricter jurisdictions may require up to 15 feet if the plumbing vent is below the level of the adjacent opening. Always consult your local building department before cutting holes in your roof, as local codes supersede national models.

For a deeper understanding of how building codes are developed and standardized across different regions, you can refer to the comprehensive overview provided by Wikipedia.

How Do You Measure the Distance Correctly?

Measuring for code compliance is not as simple as pulling out a tape measure and guessing. Precision is key to passing inspection and ensuring safety. Here is a step-by-step guide on how to accurately determine the separation between your plumbing vent and other roof openings.

Step-by-Step Measurement Guide

- Identify the Termination Points: Locate the exact point where your plumbing stack exits the roof flashing. Then, identify the nearest edge of the conflicting vent (e.g., the edge of a ridge vent or the opening of a gable vent).

- Establish the Horizontal Plane: Imagine a straight horizontal line connecting the two points. Do not measure along the slope of the roof; the code requires the horizontal projection.

- Use a Laser Measure or String: For accuracy, use a laser distance measurer set to horizontal mode. If using a tape measure, hold it perfectly level between the two points. Drooping the tape along the roof pitch will give you a false, longer measurement that could fail inspection.

- Account for Overhangs: If the nearby vent is a soffit vent under an eave, measure to the outermost edge of the soffit opening, not the fascia board.

- Document the Measurement: Take a photo with your measuring tape clearly visible for your records and for the building inspector.

Pro Tip: If you are within 1 foot of the limit (e.g., you measure 9 feet when 10 is required), do not risk it. Wind turbulence can carry gases further than expected. It is always better to relocate the vent or extend the pipe to achieve a comfortable buffer zone of 12+ feet.

What Happens If Vents Are Too Close Together?

Ignoring the minimum distance for a plumbing vent from a roof vent can lead to a cascade of problems ranging from minor annoyances to life-threatening situations. Understanding these consequences highlights why cutting corners is never an option.

The Risks of Improper Spacing

- Sewer Gas Intrusion: The most immediate danger is the re-entry of sewer gases into the home. These gases contain methane (which is explosive in high concentrations) and hydrogen sulfide (which smells like rotten eggs and is toxic). Prolonged exposure can cause headaches, nausea, dizziness, and in extreme cases, loss of consciousness.

- Trap Siphonage: When wind blows across a poorly spaced vent, it can create negative pressure (Bernoulli’s principle) that sucks the water out of your P-traps. Once the water seal is gone, there is nothing stopping gases from flowing freely into your bathroom or kitchen.

- Failed Inspections: If you are renovating or building new, an inspector will immediately flag violations. This means tearing out finished roofing, redoing flashings, and paying for double labor costs.

- Reduced System Efficiency: Even if gas doesn’t enter the home, improper spacing can cause “wind locking,” where strong winds prevent the stack from breathing. This leads to slow draining sinks and gurgling toilets.

Real-World Scenario

Consider a case study from a residential renovation in Ohio. A contractor installed a new bathroom vent only 6 feet from an existing attic turbine vent to save on piping costs. Within weeks, the homeowners reported a persistent sewage smell whenever the wind blew from the north. Upon investigation, it was found that the turbine vent was pulling the sewer exhaust directly into the attic, which then leaked into the second-floor bedrooms. The fix required removing the roof shingles, extending the plumbing vent 15 feet away, and reinstalling the flashing—a cost three times higher than doing it right the first time.

Can You Use Extensions or Deflectors to Reduce Distance?

A common follow-up question is whether there are “hacks” to avoid moving the pipe if space is tight. While some products claim to solve spacing issues, the code is generally strict about physical separation.

Vent Extensions: Yes, you can often extend the height of your plumbing vent. By raising the vent pipe higher above the roofline (typically extending it at least 12 inches above the highest point of the roof within a 10-foot radius), you can sometimes mitigate dispersion issues. However, this does not automatically waive the 10-foot horizontal rule regarding windows and intake vents. The vertical height helps disperse gases upward, but horizontal proximity to an intake remains a primary concern.

Deflectors and Caps: Specialized vent caps with deflectors can help direct gases upward and away from the immediate area. While these are excellent for preventing rain and snow entry, most building inspectors do not accept them as a substitute for the mandated horizontal distance. Relying on a cap to bypass the 10-foot rule is a risky strategy that will likely result in a failed inspection.

If you are physically constrained by your roof design, the only code-compliant solution is usually to reroute the plumbing vent internally within the walls or attic space until it can exit the roof at a compliant location.

Frequently Asked Questions (FAQ)

1. Does the 10-foot rule apply to non-openable windows?

Generally, no. The strict 10-foot rule typically applies to openable windows, doors, and air intakes where people might be breathing or where fresh air is actively drawn in. For fixed, non-openable windows, the requirement is often reduced (sometimes to 4 feet), but this varies significantly by local jurisdiction. Always check your specific city code.

2. What if my roof vent is higher than the plumbing vent?

If the conflicting vent (like an attic vent) is significantly higher than your plumbing vent, the risk of gas falling into it is lower, but the code usually still mandates the horizontal separation. However, if the plumbing vent is terminated at least 2 feet higher than the top of the nearby opening, some codes may allow a reduced horizontal distance. This is a complex exception that requires explicit approval from your local building official.

3. Can I combine my plumbing vent with my HVAC exhaust?

Absolutely not. Plumbing vents and HVAC (heating, ventilation, and air conditioning) exhausts must never be combined or placed in the same chase without strict separation. Mixing sewer gases with combustion exhaust or fresh air intake is a severe code violation and a major health hazard. They must maintain the standard minimum distance from each other.

4. How far must a plumbing vent be from the property line?

While the distance from other vents is usually 10 feet, the distance from the property line is different. Many codes require vents to be at least 5 to 10 feet from the property line to prevent disputes with neighbors regarding odors. Again, this is highly dependent on local zoning laws and should be verified before installation.

5. Do I need a permit to move a plumbing vent?

Yes. Altering the plumbing ventilation system almost always requires a building permit because it affects the safety and sanitation of the structure. Unpermitted work can lead to fines, difficulties when selling your home, and potential liability issues if a problem arises later.

6. What material should I use for extending the vent on the roof?

For the portion of the vent extending through the roof, you should use materials rated for exterior exposure and UV resistance. Typically, this means continuing with the same schedule 40 PVC used indoors (if allowed by code in your area) or switching to cast iron or copper for the final rise, depending on local fire codes. Ensure all joints are properly primed and glued to prevent leaks.

Conclusion

Ensuring the correct minimum distance for a plumbing vent from a roof vent is a fundamental aspect of home safety and plumbing integrity. By adhering to the standard 10-foot horizontal rule, you protect your family from toxic sewer gases, prevent annoying drainage issues, and ensure your home passes all necessary building inspections. While it might be tempting to take shortcuts when space is limited, the long-term risks far outweigh the initial effort of doing it correctly.

Remember, plumbing codes are written in blood and experience—they exist to keep you safe. If you are unsure about your specific roof layout or local amendments, do not hesitate to consult with a licensed plumber or your local building department. Taking the time to get these details right today saves you from costly repairs and health scares tomorrow.

Found this guide helpful? Share this article with your fellow DIY enthusiasts, contractors, or homeowners on Facebook, Twitter, and LinkedIn to help spread awareness about plumbing safety standards!

Leave a Reply