If you’ve ever stood in front of a leaking pipe wondering why your torch isn’t heating evenly or taking forever to melt solder, you’re not alone. Many DIYers and even professional plumbers struggle with choosing the right equipment for the job. The secret often lies in selecting the best size torch head to use for plumbing with acetylene. Using the wrong size can lead to weak joints, wasted gas, or even dangerous situations. In this guide, we’ll break down exactly what you need to know to pick the perfect torch head, ensuring efficient, safe, and professional-quality results every time.

Why Torch Head Size Matters in Plumbing

When working with copper pipes and fittings, heat control is everything. Too little heat, and the solder won’t flow; too much, and you risk burning through the pipe or damaging nearby components. The size of your torch head directly influences the flame’s intensity, spread, and precision.

According to industry standards, most residential plumbing tasks involve pipes ranging from ½ inch to 2 inches in diameter. For these sizes, a medium-sized torch head typically offers the best balance between power and control. Larger heads are reserved for heavy-duty applications like thick-walled pipes or industrial systems, while smaller heads suit delicate work such as electronics or jewelry—but those are rarely used in standard plumbing.

Pro Tip: Always match your torch head size to the largest pipe diameter you expect to work on regularly. This ensures versatility without sacrificing performance.

What Is the Best Size Torch Head for Standard Plumbing?

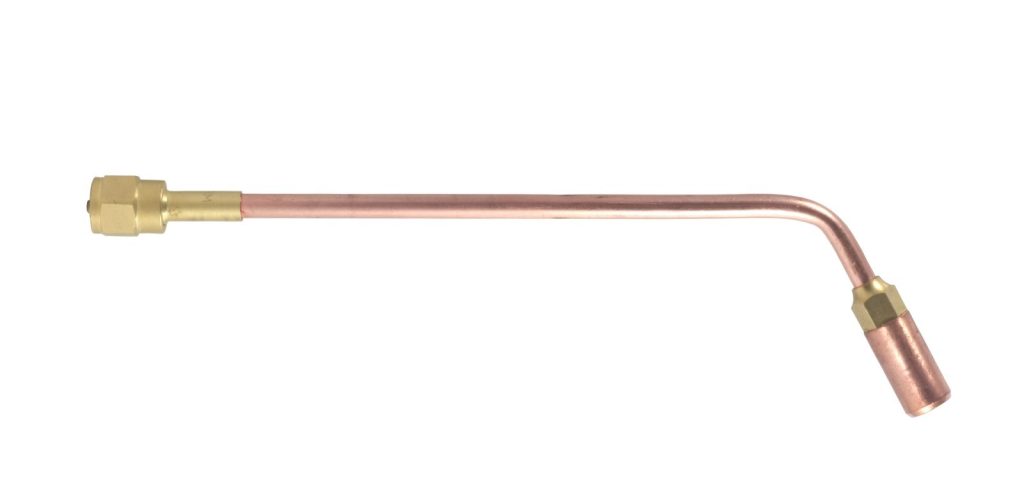

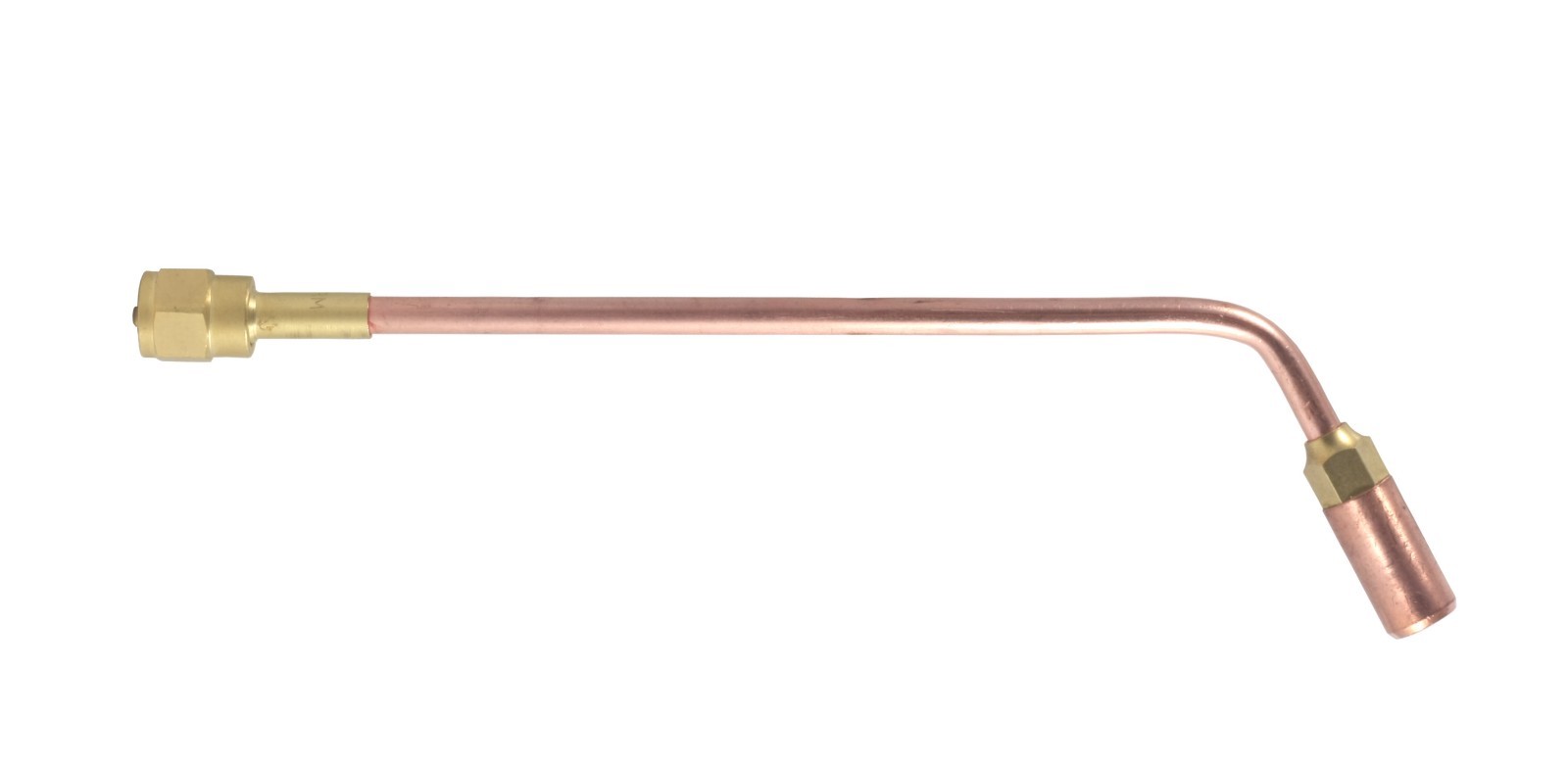

For typical home plumbing repairs involving copper pipes up to 1 inch in diameter, a Type 3 or Type 4 torch head paired with an acetylene tank is widely considered ideal. These heads produce a concentrated yet sufficiently broad flame that heats joints evenly without overheating surrounding areas.

Comparison Table: Common Torch Head Sizes for Plumbing

| Torch Head Type | Flame Spread | Ideal Pipe Diameter | Best Use Case |

|---|---|---|---|

| Type 1 | Narrow | Under ½” | Delicate soldering, small fittings |

| Type 2 | Medium-Narrow | ½” – ¾” | General household repairs |

| Type 3 | Medium | ¾” – 1″ | Most common plumbing jobs |

| Type 4 | Medium-Wide | 1″ – 2″ | Larger residential/main lines |

| Type 5+ | Wide | Over 2″ | Industrial/commercial applications |

As shown above, Type 3 strikes the optimal balance for most plumbers. It provides enough heat output to handle standard joint sizes while maintaining maneuverability in tight spaces under sinks or behind walls.

How to Choose the Right Torch Head Based on Your Project

Not all plumbing jobs are created equal. Before purchasing or switching torch heads, consider the following factors:

1. Pipe Material and Thickness

Copper is the most common material in residential plumbing, but its thickness varies. Thicker walls (like Type L or K copper) require more heat than thinner Type M pipes. A larger torch head may be necessary for thicker materials to ensure proper penetration.

2. Joint Accessibility

Tight corners and confined spaces demand a smaller, more precise flame. If you frequently work in cramped conditions, a slightly smaller head (Type 2) might offer better control despite slower heating times.

3. Frequency of Use

Occasional DIYers may benefit from a versatile mid-size head (Type 3), whereas professionals who tackle diverse projects daily might invest in multiple heads or adjustable models.

4. Fuel Type Compatibility

While this article focuses on acetylene, remember that some torch heads are designed specifically for propane or MAP-Pro gas. Ensure compatibility between your regulator, hose, and torch head to avoid inefficiency or hazards.

Step-by-Step Guide: Using an Acetylene Torch for Plumbing

Once you’ve selected the best size torch head to use for plumbing with acetylene, follow these steps for safe and effective soldering:

- Prepare the Work Area

Clear flammable materials, ensure ventilation, and wear protective gear (gloves, goggles, fire-resistant clothing). - Clean the Pipes and Fittings

Use emery cloth or a wire brush to remove oxidation. Apply flux evenly to both the pipe end and fitting interior. - Assemble the Torch System

Connect the acetylene tank to the regulator, attach the hose, and screw on your chosen torch head securely. Check for leaks using soapy water. - Light the Torch Safely

Open the acetylene valve slightly, ignite with a striker, then adjust oxygen (if using oxy-acetylene) until you achieve a neutral blue flame. - Heat the Joint Evenly

Move the flame around the fitting—not just one spot—to distribute heat uniformly. Once the flux bubbles and turns clear, touch the solder to the joint. It should melt and draw into the gap via capillary action. - Cool and Inspect

Allow the joint to cool naturally. Wipe away excess flux and check for gaps or uneven solder distribution.

⚠️ Safety Note: Never leave a lit torch unattended. Always shut off the acetylene at the tank first, then release pressure from the line before storing.

For deeper technical understanding of combustion principles and gas properties, refer to this authoritative resource on Acetylene – Wikipedia.

Common Mistakes to Avoid When Using Acetylene Torches

Even experienced plumbers make errors when rushing or using improper tools. Here are frequent pitfalls—and how to avoid them:

- Using Too Large a Torch Head: Causes overheating, warping, or burn-through on thin pipes.

- Insufficient Cleaning: Leads to poor solder adhesion and potential leaks.

- Improper Flame Adjustment: A carburizing (sooty) or oxidizing (hissing) flame compromises joint integrity.

- Skipping Flux Application: Prevents proper wetting and flow of solder.

- Rushing the Cooling Process: Quenching hot joints with water can cause cracks or weaken connections.

By avoiding these mistakes and pairing them with the correct torch head size, you significantly increase success rates and reduce rework.

FAQ Section

Q1: Can I use a propane torch instead of acetylene for plumbing?

Yes, propane torches are suitable for small-diameter copper pipes (up to ¾”). However, acetylene burns hotter (~3,100°C vs. ~2,000°C for propane), making it far more effective for larger pipes and faster workflow.

Q2: How do I know if my torch head is too big?

Signs include scorched pipes, melted flux before solder application, difficulty controlling the flame in tight spaces, and excessive fuel consumption.

Q3: Are adjustable torch heads worth buying?

Adjustable heads offer flexibility across different job types but may lack the precision of fixed-size heads optimized for specific tasks. They’re great for beginners or mobile technicians handling varied assignments.

Q4: What safety gear should I wear when using an acetylene torch?

Always wear flame-resistant gloves, safety glasses with side shields, long sleeves made of natural fibers (no synthetics), and closed-toe shoes. Keep a fire extinguisher nearby.

Q5: How often should I replace my torch head?

Inspect regularly for clogs, cracks, or wear. With proper maintenance, a quality brass torch head can last years. Replace immediately if damaged or if flame patterns become inconsistent.

Q6: Is acetylene safe for indoor plumbing work?

Only with extreme caution. Acetylene produces carbon monoxide and requires excellent ventilation. Whenever possible, perform soldering outdoors or in well-ventilated areas with fans running.

Conclusion

Choosing the best size torch head to use for plumbing with acetylene isn’t just about convenience—it’s a critical decision affecting safety, efficiency, and the longevity of your repairs. For most residential applications, a Type 3 or Type 4 torch head delivers the ideal combination of heat output and control. By understanding your project needs, avoiding common mistakes, and following best practices, you’ll achieve clean, durable joints every time.

Don’t let outdated tools hold back your craftsmanship. Share this guide with fellow DIY enthusiasts or apprentice plumbers looking to upgrade their skills. Whether you’re fixing a leaky faucet or installing new supply lines, having the right torch setup makes all the difference. Stay safe, stay precise, and keep mastering your trade—one perfectly soldered joint at a time.

Leave a Reply