Are you struggling to fit a full-size laundry routine into a small apartment, closet, or utility nook? You are not alone; millions of American homeowners face space constraints that make traditional side-by-side units impossible. The solution often lies in a vertical configuration, but installing it correctly requires a precise over and under washer and dryer vent and plumbing diagram to avoid leaks, fire hazards, and code violations. In this guide, we will walk you through exactly how to plan, visualize, and execute a safe and efficient stacked laundry installation.

Understanding the Basics of Stacked Laundry Systems

Before diving into the technical diagrams, it is crucial to understand why the vertical arrangement differs significantly from standard setups. When you place a dryer on top of a washer (or vice versa, though less common), the dynamics of gravity, vibration, and airflow change dramatically.

Most modern “all-in-one” stackable units are designed by manufacturers to work together seamlessly. However, many homeowners opt to stack two separate units using a stacking kit. This approach demands careful attention to the plumbing and venting infrastructure. According to industry data, improper installation accounts for nearly 15% of all laundry-related home insurance claims in the US, primarily due to water leaks and lint fires.

The core challenge is managing three distinct systems in a compressed vertical space:

- Water Supply and Drainage: Handling heavy water flow and potential backflow.

- Electrical Connections: Ensuring separate circuits for high-voltage dryers and standard washers.

- Exhaust Venting: Routing hot, moist air safely outside without long, restrictive turns.

Critical Components of the Plumbing Diagram

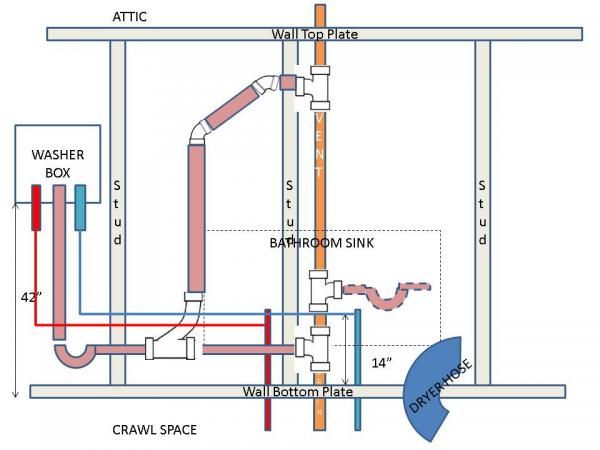

When reviewing an over and under washer and dryer vent and plumbing diagram, the plumbing section is often where mistakes happen. Water is heavy, and gravity is unforgiving. Here is what your diagram must clearly illustrate.

Water Supply Lines

Your diagram should show two distinct hot and cold water lines terminating behind the unit.

- Pressure Requirements: Ensure both lines maintain between 20 and 116 psi (pounds per square inch).

- Shut-off Valves: Install individual shut-off valves for the washer. Dryers generally do not require water unless they are steam models.

- Connection Type: Use braided stainless steel hoses rather than rubber ones. They are less prone to bursting under pressure fluctuations.

The Drainage System

The drain is the most critical aspect of the vertical setup. If the washer is on the bottom, the drain hose usually exits directly into a standpipe. If the washer is on top (rare in DIY stacks but common in all-in-ones), the drain path is longer.

| Component | Specification | Why It Matters |

|---|---|---|

| Standpipe Height | 18 to 42 inches above floor | Prevents siphoning of water from the drum. |

| Pipe Diameter | Minimum 2 inches | Handles rapid discharge volumes (up to 17 gallons/min). |

| Air Gap | 6 inches minimum | Stops dirty sewer water from flowing back into the machine. |

| P-Trap Location | Within 6 feet of the unit | Blocks sewer gases from entering the home. |

Pro Tip: Never push the drain hose more than 6 inches into the standpipe. Doing so creates an airtight seal that can cause the washer to siphon its own water out during the cycle, leading to error codes and incomplete washes.

Mastering the Venting Configuration

Venting a dryer located above a washer presents unique challenges, especially if the exhaust outlet is at the rear of the unit and your wall vent is low. A proper over and under washer and dryer vent and plumbing diagram will prioritize the shortest, straightest path to the exterior.

The Physics of Lint and Airflow

Dryer vents rely on positive pressure to push hot, humid air and lint particles outside. Every 90-degree elbow you add to the ductwork reduces the efficiency of the dryer by approximately 10%. Long, convoluted paths cause lint to accumulate, which is the leading cause of residential dryer fires.

According to the National Fire Protection Association (NFPA), failure to clean dryers and vents results in thousands of fires annually. Your diagram must account for this by minimizing bends.

Recommended Venting Materials

- Rigid Metal Ducts (Aluminum or Galvanized Steel): These are the gold standard. They have smooth interiors that resist lint buildup and are non-combustible.

- Semi-Rigid Metal Ducts: Acceptable for short transitions behind the unit where flexibility is needed, but avoid crushing them.

- Forbidden Materials: Never use plastic or foil accordion-style ducts. They trap lint easily, sag over time, and are highly flammable. Most US building codes explicitly ban these materials.

Calculating Equivalent Length

When drawing your diagram, you must calculate the “equivalent length” of your vent run to ensure your dryer can handle it.

- Straight pipe: 1 foot = 1 foot of equivalent length.

- 90-degree elbow: Adds 5 feet of equivalent length.

- 45-degree elbow: Adds 2.5 feet of equivalent length.

- Wall cap: Adds 2.5 feet of equivalent length.

Most standard dryers can handle a maximum equivalent length of 35 feet. If your diagram exceeds this, you will need to install a booster fan or reconfigure the layout.

Step-by-Step Installation Guide

Follow this concrete procedure to translate your diagram into reality. Precision here ensures longevity and safety.

- Prepare the Space: Clear the area completely. Verify the floor is level; an unlevel floor causes excessive vibration, which can loosen plumbing connections over time. Use a bubble level and adjust the appliance feet until the unit is stable.

- Install the Stacking Kit: If using separate units, attach the manufacturer-approved stacking kit to the washer first. Never stack a dryer on a washer without a certified kit; the vibrations will cause the top unit to slide off.

- Connect Water Lines: Attach the braided hoses to the hot and cold valves. Tighten by hand, then give a quarter-turn with pliers. Do not overtighten, as this can strip the threads. Turn the water on slowly and check for drips for 5 minutes.

- Secure the Drain Hose: Insert the drain hose into the standpipe. Secure it with a hose clamp or a specialized bracket to prevent it from jumping out during the spin cycle. Ensure the height is between 30 and 48 inches from the floor.

- Route the Vent Duct: Connect the rigid metal duct to the dryer outlet. Use aluminum foil tape (not duct tape) to seal joints. Push the unit gently into place, ensuring the duct does not kink or crush against the wall.

- Electrical Hookup:

- Washer: Plug into a standard 120V grounded outlet.

- Dryer: Connect to a dedicated 240V circuit (for electric) or gas line (for gas models). Warning: Gas connections should always be verified by a licensed professional to check for leaks using a soap solution.

- Test Run: Run a short “rinse and spin” cycle on the washer and a 10-minute air-fluff cycle on the dryer. Check all connection points again for leaks, air escaping, or unusual noises.

Common Mistakes to Avoid

Even with a good diagram, execution errors occur. Be wary of these frequent pitfalls:

- Crushing the Vent: Pushing the stacked unit too close to the wall often flattens the flexible transition duct, restricting airflow by up to 80%. Leave at least 4–6 inches of clearance behind the unit.

- Ignoring the Trap Primer: In rare cases where the laundry room sees little use, the P-trap water can evaporate, letting sewer gas in. Pour a cup of water down the drain monthly if the machine sits idle.

- Mixing Up Hot/Cold: While modern washers can adjust, connecting hot water to the cold inlet wastes energy and may damage certain fabrics during cold wash cycles.

- Using the Wrong Screw Types: When securing the stacking kit, use only the provided hardware. Standard wood screws or mismatched bolts can strip out under the dynamic load of a spinning drum.

FAQ Section

Q1: Can I stack any washer and dryer together?

A: No. You should only stack units that are explicitly designed to be stackable or use a universal stacking kit certified for your specific models. Mismatched widths or depths can create unstable centers of gravity, leading to dangerous tipping hazards.

Q2: What is the minimum ceiling height required for an over-and-under setup?

A: You typically need a ceiling height of at least 7 feet (84 inches). This allows for the combined height of the machines (usually around 75–78 inches), plus the stacking kit, plus roughly 4–6 inches of clearance at the top for ventilation and maneuvering the units into place.

Q3: Is it okay to vent the dryer indoors to save heat in winter?

A: Absolutely not. Venting a dryer indoors releases massive amounts of moisture, which leads to mold growth and structural damage within weeks. Furthermore, it introduces lint particles and potentially carbon monoxide (if gas-powered) into your living space. Always vent to the outdoors.

Q4: My drain hose keeps slipping out of the standpipe. How do I fix this?

A: This is usually caused by the force of the pump discharge. You can purchase a “drain hose guide” or “standpipe hook” at any hardware store. These devices clamp onto the standpipe and hold the hose securely in place while maintaining the necessary air gap.

Q5: Do I need a permit to install a stacked washer and dryer?

A: Regulations vary by municipality. Generally, replacing existing appliances does not require a permit. However, if you are moving plumbing lines, adding new electrical circuits, or altering gas lines, most US jurisdictions require a permit and a final inspection to ensure code compliance.

Q6: How often should I clean the vent on a stacked unit?

A: Because stacked units often have slightly more complex vent paths, you should clean the lint trap after every load and perform a deep clean of the entire vent duct system at least once a year. If you notice drying times increasing, clean it immediately.

Conclusion

Creating a functional and safe laundry space in a compact area is entirely achievable with the right planning. By utilizing a detailed over and under washer and dryer vent and plumbing diagram, you ensure that water flows correctly, air vents efficiently, and your appliances operate safely for years to come. Remember, the key to success lies in respecting the physics of water and air, adhering to local building codes, and never cutting corners on materials like rigid metal ducting and braided hoses.

Did you find this guide helpful for your home improvement project? Share this article with your friends on Facebook, Pinterest, or Twitter who might be tackling their own laundry room makeover! Let’s help everyone build safer, smarter homes.

Leave a Reply