Building or renovating a home with an upper floor while relying on a private well can feel like walking a tightrope between water pressure and pipe durability. Many homeowners struggle with weak showers upstairs or noisy pipes that bang when faucets shut off. If you are navigating PEX rough plumbing for a house with an upstairs on a well system, you need a strategy that balances flow rate, pressure consistency, and long-term reliability. This guide breaks down exactly how to design and install a robust PEX system tailored specifically for multi-story homes powered by well water.

Why Choose PEX for Multi-Story Well Homes?

When dealing with a well system, water pressure fluctuates more than in municipal setups. Unlike city water, which maintains a steady PSI, well systems depend on pump cycles and pressure tank settings. This makes the choice of piping material critical.

Cross-linked Polyethylene (PEX) has become the industry standard for new constructions, particularly for complex layouts involving multiple floors. According to data from the Plastics Pipe Institute, PEX installations have grown by over 40% in the residential sector since 2015 due to their flexibility and resistance to scale buildup—a common issue in hard well water.

Key Advantages of PEX in Well Systems

- Freeze Resistance: PEX can expand slightly if water freezes, reducing the likelihood of bursting compared to rigid copper or CPVC.

- Corrosion Immunity: Well water often contains minerals like iron or sulfur. PEX does not corrode, ensuring cleaner water and longer pipe life.

- Fewer Fittings: Because PEX comes in long rolls, you can snake it through walls and floors with minimal connections, significantly lowering the risk of leaks inside your walls.

- Quiet Operation: The material dampens the sound of rushing water and eliminates the “water hammer” noise often heard in rigid pipe systems when pumps kick on.

For a deeper understanding of polymer materials used in construction, you can refer to this overview on Wikipedia.

Critical Sizing Strategies for Upstairs Flow

One of the most frequent questions homeowners ask is: “Why is my upstairs shower weak?” In a two-story home on a well, gravity works against you. Every foot of vertical rise reduces pressure by approximately 0.43 PSI. If your well pump is set to cut off at 50 PSI, by the time water reaches a second-floor bathroom 20 feet up, you have already lost nearly 9 PSI before friction even enters the equation.

To combat this, proper pipe sizing during the rough-in phase is non-negotiable.

The Manifold System vs. Traditional Trunk-and-Branch

For upstairs applications, a home-run manifold system is superior to traditional trunk-and-branch layouts.

- Trunk-and-Branch: Uses one large main line that splits into smaller lines. Fixtures furthest from the source (often upstairs) suffer from pressure drops when other fixtures are used.

- Manifold System: Runs individual PEX lines from a central hub directly to each fixture. This ensures that flushing a toilet downstairs does not steal pressure from an upstairs shower.

Recommended Pipe Diameters

| Fixture Type | Recommended PEX Size | Reason |

|---|---|---|

| Main Supply Line (Well to House) | 1 inch or 1.25 inch | Maximizes volume from the pressure tank. |

| Manifold to Bathtub/Shower | 3/4 inch | Ensures high flow rate for comfort. |

| Manifold to Sink/Toilet | 1/2 inch | Sufficient for low-volume fixtures. |

| Recirculation Loop (if applicable) | 1/2 inch | Maintains hot water temperature. |

Expert Tip: Never reduce pipe size until the very last connection at the fixture valve. Keeping lines at 3/4 inch all the way to the upstairs bathroom wall can dramatically improve perceived pressure.

Step-by-Step Installation Guide for Well Systems

Installing PEX rough plumbing for a house with an upstairs on a well system requires precision. Unlike city water, well systems introduce variables like sediment and variable pump start-stop cycles. Follow these concrete steps to ensure a professional-grade rough-in.

Step 1: Assess Pump Capacity and Pressure Tank

Before cutting any pipe, verify your well pump’s Gallons Per Minute (GPM) rating. A standard residential pump usually delivers 10–20 GPM.

- Calculate total demand: Add up the GPM requirements of all fixtures likely to run simultaneously (e.g., two showers + washing machine = ~12 GPM).

- Ensure your pressure tank is sized correctly. For a two-story home, a larger tank (e.g., 86 gallons drawdown) reduces pump cycling, protecting the PEX from pressure surges.

Step 2: Install the Central Manifold

Locate your manifold in an accessible area, ideally on the main floor or in a utility closet centrally located between floors.

- Mount the manifold securely to a stud using metal straps.

- Connect the main supply line from the pressure tank to the manifold inlet using a 1-inch PEX-A line.

- Use brass or poly-alloy fittings; avoid cheap plastic fittings for main connections.

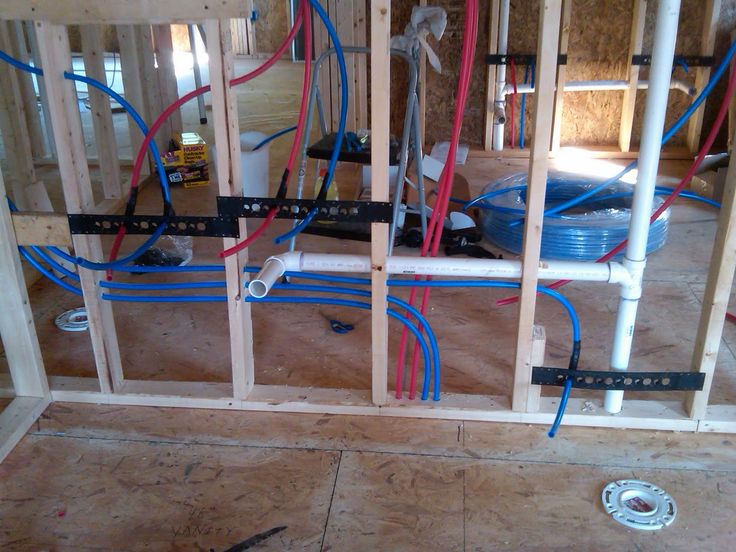

Step 3: Run Lines to the Second Floor

Drill holes through top plates and floor joists carefully.

- Hole Sizing: Drill holes 1 inch larger than the pipe diameter to allow for expansion and contraction without squeaking.

- Protection: Where PEX passes through concrete slabs or foundation walls, sleeve the pipe with a larger conduit to prevent abrasion.

- Routing: Run lines vertically through interior walls rather than exterior walls to prevent freezing risks in winter.

Step 4: Secure and Support the PEX

PEX must be supported every 32 inches on horizontal runs and every 6–10 feet on vertical runs.

- Use wide plastic hangers or copper-plated straps. Never use narrow metal staples that can crush the pipe.

- Leave a small amount of slack (about 1 inch per 10 feet) to accommodate thermal expansion when hot water flows.

Step 5: Pressure Testing Before Closing Walls

This is the most critical step for well systems.

- Cap all open ends with test plugs.

- Connect a pneumatic pump or use the well pump to fill the system.

- Pressurize the system to 1.5 times the operating pressure. If your well cuts off at 60 PSI, test at 90 PSI.

- Hold this pressure for 24 hours. A drop of more than 2-3 PSI indicates a leak that must be found and fixed before drywall installation.

Addressing Common Well Water Challenges

Well water presents unique challenges that municipal water does not. When planning your PEX rough plumbing for a house with an upstairs on a well system, you must account for water quality and pressure dynamics.

Sediment and Filtration

Well water often carries sand, silt, or iron particles. These abrasives can wear down valve seats over time.

- Solution: Install a whole-house sediment filter immediately after the pressure tank and before the manifold. A 5-micron spun polyester filter is usually sufficient for general sediment.

- Maintenance: Plan for easy access to change filters every 3–6 months depending on usage.

Pressure Fluctuations

Well pumps cycle on and off. This creates pressure waves that travel through pipes.

- Solution: Install a water hammer arrestor near the manifold and potentially near quick-closing valves (like washing machines) on the upper floor. While PEX absorbs some shock, arrestors provide extra protection for fixtures.

Temperature Control

In long runs to the second floor, users often wait too long for hot water, wasting both water and energy.

- Solution: Consider installing a demand-controlled recirculation pump. This keeps hot water moving in a loop only when needed, ensuring instant hot water upstairs without running the pump continuously.

Frequently Asked Questions (FAQ)

1. Can I use PEX-B for a two-story home on a well?

Yes, PEX-B is suitable for multi-story homes and is generally less expensive than PEX-A. However, PEX-A has higher flexibility and better memory (resistance to kinking), which makes it slightly easier to install in tight spaces typical of upstairs retrofits. Both types handle well water pressure effectively if sized correctly.

2. What is the ideal pressure setting for a well serving an upstairs?

For a two-story home, a pressure switch setting of 40/60 PSI is the minimum recommendation. Many experts suggest upgrading to a 50/70 PSI setting if your pump and tank can handle it. This provides a stronger baseline pressure to overcome the gravitational loss on the second floor. Always consult your pump manufacturer’s limits before adjusting.

3. Do I need a booster pump for the second floor?

Not always. If your well yields sufficient GPM and your pressure tank is set to 50/70 PSI, proper pipe sizing (using 3/4″ lines to bathrooms) is usually enough. A booster pump is typically only necessary if the house has three or more stories or if the well output is inherently low (under 8 GPM).

4. How do I prevent pipes from freezing in the attic or upstairs walls?

Never run PEX water lines in unheated attics or exterior wall cavities in cold climates. Always route plumbing through interior conditioned spaces. If you must cross an uninsulated space, wrap the PEX in foam insulation sleeves rated for your local climate zone and consider adding heat tape for extreme conditions.

5. Is a manifold system worth the extra cost for a small upstairs?

Absolutely. Even for just one or two upstairs bathrooms, a manifold system ensures consistent pressure. In a trunk-and-branch system, someone flushing a toilet on the first floor can cause a scalding event in an upstairs shower. The manifold isolates these events, providing safety and comfort that justifies the initial material cost.

6. How often should I check my well-based PEX system?

While PEX is durable, you should visually inspect exposed lines in basements or crawl spaces annually for signs of rodent damage or UV degradation (PEX cannot be exposed to sunlight). Additionally, monitor your pressure gauge; erratic needle movement may indicate a failing pressure tank bladder, which stresses the plumbing system.

Conclusion

Designing PEX rough plumbing for a house with an upstairs on a well system is about more than just connecting pipes; it is about engineering a balanced ecosystem of pressure, flow, and durability. By choosing the right pipe diameters, utilizing a manifold distribution system, and accounting for the unique quirks of well water, you can ensure that every faucet in your home—from the kitchen sink to the master shower upstairs—delivers strong, consistent performance.

Remember, the rough-in phase is your one chance to get it right behind the walls. Taking the time to size correctly, support properly, and test thoroughly will save you thousands in repairs and frustration down the road.

Did you find this guide helpful for your upcoming project? Share this article with your contractor, builder, or fellow DIY enthusiasts on social media to help them build better, more efficient homes!

Leave a Reply