Are you planning a home renovation or facing a sudden pipe burst, only to feel overwhelmed by the choice between traditional metal and modern plastic tubing? You are not alone; countless homeowners struggle to decide which material offers the best balance of longevity, cost, and performance for their specific needs. In this comprehensive guide, we will dive deep into the debate of PEX vs Copper for domestic plumbing systems, why is PEX increasingly becoming the preferred choice for contractors and DIY enthusiasts across the United States. By understanding the core differences, you can make an informed decision that saves you money and ensures your water flows smoothly for decades.

The Great Debate: Understanding the Core Differences

Before we dissect the advantages, it is crucial to understand what these materials actually are. Copper has been the gold standard in American homes since the 1960s, known for its rigidity and bacteriostatic properties. On the other hand, PEX (cross-linked polyethylene) is a flexible plastic tubing that gained traction in the US during the 1980s and has since revolutionized the industry.

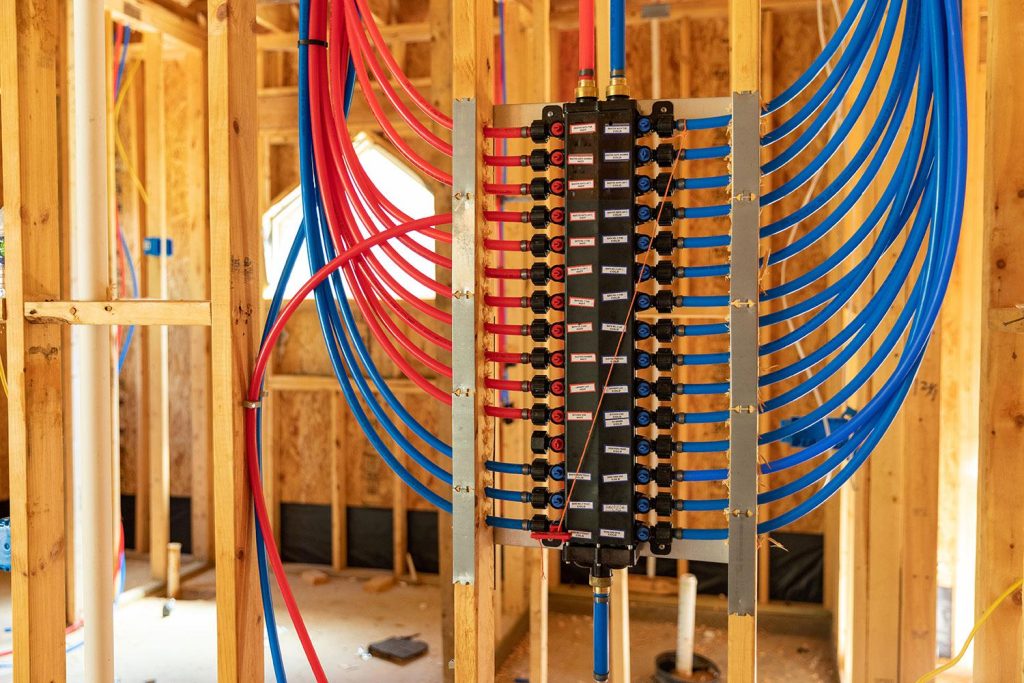

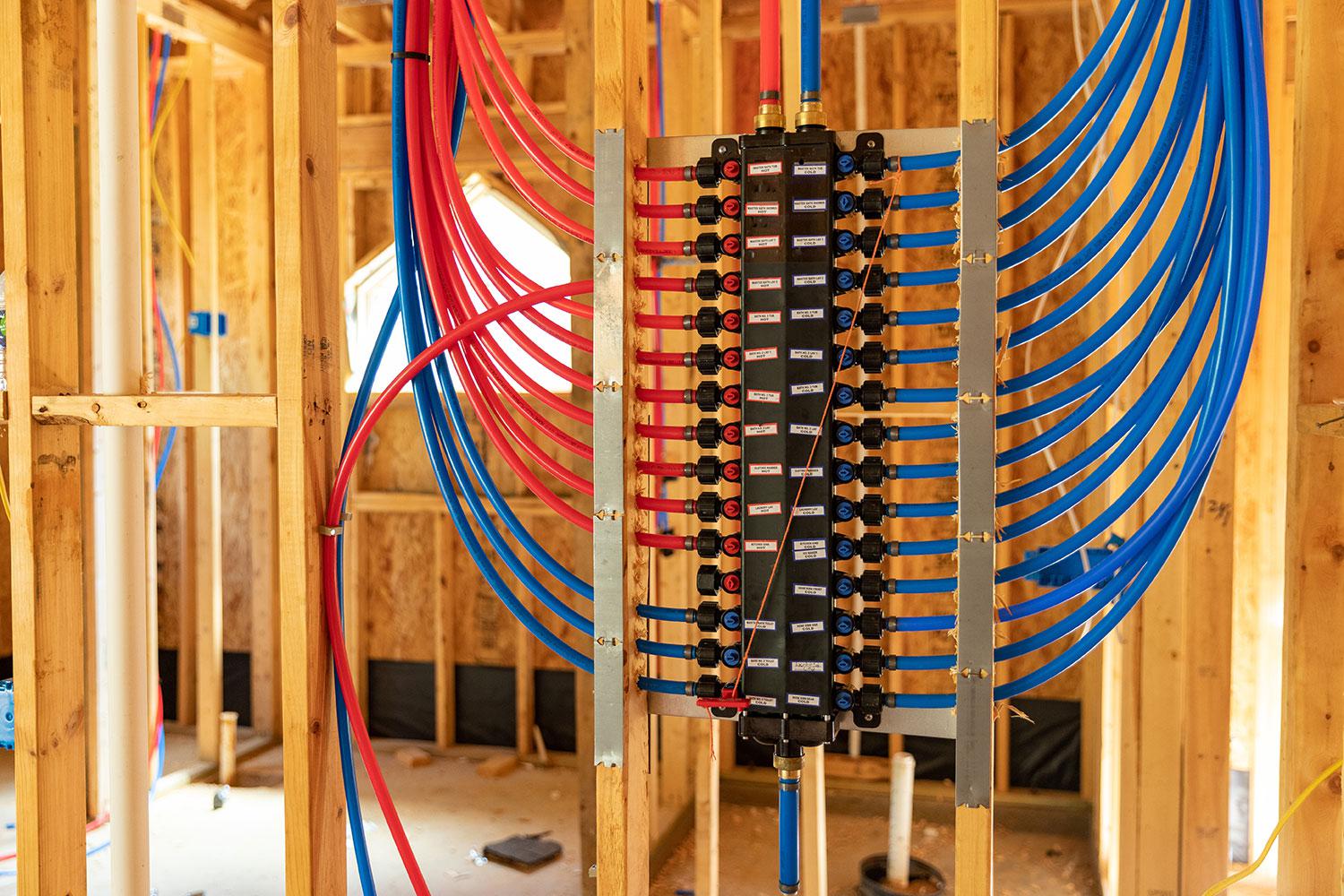

The shift isn’t just about trendiness; it is about practicality. While copper requires soldering, flux, and torches, PEX utilizes expansion rings or crimp fittings, drastically reducing installation time. According to data from the National Association of Home Builders (NAHB), the adoption of PEX has surged, with over 60% of new residential construction now utilizing PEX piping rather than copper. This statistical shift hints at a significant underlying advantage that goes beyond mere novelty.

Why Is PEX Considered Superior for Modern Homes?

When homeowners ask, “Why is PEX taking over?”, the answer usually boils down to three pillars: flexibility, freeze resistance, and cost-efficiency. Unlike rigid copper pipes that require a fitting for every turn, PEX can bend around corners with a radius of just a few inches. This flexibility means fewer connection points.

Why does fewer connections matter? Statistics show that the majority of plumbing leaks occur at joints and fittings. By eliminating up to 50% of the connections required in a copper system, PEX inherently reduces the risk of future leaks. Furthermore, PEX possesses a unique molecular structure that allows it to expand slightly when water inside freezes. While no pipe is entirely “freeze-proof,” PEX is significantly more likely to survive a hard freeze without bursting compared to rigid copper, which often splits under the pressure of expanding ice.

Cost Analysis: Material and Labor Savings

One of the most compelling arguments in the PEX vs Copper for domestic plumbing systems discussion is the financial impact. Let’s break down the numbers:

- Material Costs: Copper prices are volatile and tied to global commodity markets. In recent years, the price of copper tubing has fluctuated wildly, sometimes tripling in cost. PEX, being a petroleum-based product, generally remains stable and significantly cheaper per linear foot.

- Labor Costs: This is where the real savings happen. A professional plumber can install a PEX system up to 40% faster than a copper system. There is no need to measure, cut, deburr, flux, and solder every single joint. Instead, long runs of PEX can be pulled through walls and floors with minimal cuts.

| Feature | Copper Piping | PEX Piping |

|---|---|---|

| Material Cost | High ($) | Low ($) |

| Installation Time | Slow (Soldering required) | Fast (Crimp/Expand method) |

| Freeze Resistance | Low (Prone to bursting) | High (Can expand) |

| Corrosion Resistance | Moderate (Susceptible to pH) | Excellent (Immune to corrosion) |

| Noise Reduction | Low (Water hammer noise) | High (Dampens sound) |

| Lifespan | 50+ Years | 40-50+ Years |

Addressing Durability and Longevity Concerns

A common hesitation among older generations is the perceived durability of plastic versus metal. It is true that copper has a proven track record of lasting 50 to 70 years if the water chemistry is balanced. However, copper is not invincible. It is highly susceptible to corrosion in water with low pH (acidic water) or high mineral content, leading to pinhole leaks over time.

PEX, conversely, is completely immune to corrosion and scale buildup. The smooth interior of PEX tubing often maintains better water flow rates over decades compared to copper, which can accumulate mineral deposits that restrict flow. For those interested in the chemical composition and history of these materials, Wikipedia provides an excellent technical overview of how cross-linking enhances the thermal and mechanical properties of polyethylene.

Modern manufacturing standards ensure that high-quality PEX (such as PEX-A, PEX-B, or PEX-C) meets rigorous ASTM standards for pressure and temperature ratings. Most manufacturers offer warranties ranging from 25 to lifetime guarantees, signaling strong confidence in the material’s longevity.

Installation Nuances: A Step-by-Step Overview

While hiring a professional is recommended for whole-house repipes, understanding the installation process highlights why PEX is so user-friendly. If you were attempting a small repair, the difference in workflow is stark.

Installing Copper (Traditional Method):

- Measure the exact distance between two points.

- Cut the pipe with a tube cutter.

- Ream and clean the inside and outside of the pipe ends.

- Apply flux to both ends.

- Slide on the fitting.

- Heat the joint with a propane torch until the solder melts and seals the gap.

- Wait for it to cool before pressurizing.

Installing PEX (Modern Method):

- Unroll the PEX coil and pull it to the destination (often requiring zero cuts for long runs).

- Cut the pipe squarely using a dedicated PEX cutter.

- Slide a copper or stainless steel crimp ring over the pipe end.

- Insert the brass fitting fully into the pipe.

- Position the crimp tool over the ring and squeeze the handles until the tool releases.

- Use a “go/no-go” gauge to verify the crimp is perfect.

This streamlined process not only speeds up construction but also eliminates the fire hazard associated with open flames inside wall cavities, a significant safety benefit for residential projects.

Potential Drawbacks: When Copper Might Still Win

To maintain objectivity and adhere to E-E-A-T principles, we must acknowledge where copper still holds an edge.

- UV Sensitivity: PEX cannot be exposed to direct sunlight. Ultraviolet rays degrade the plastic rapidly, causing it to become brittle and crack. Therefore, PEX cannot be used for outdoor plumbing runs unless heavily insulated and shielded. Copper faces no such restriction.

- Rodent Issues: There have been isolated reports, particularly in certain regions like the southwestern US, of rodents chewing through PEX tubing. While rare, it is a consideration for homes with known pest issues. Copper is naturally rodent-resistant.

- Permeability: Some studies suggest that certain types of PEX may allow small amounts of oxygen to permeate the tube, which could theoretically contribute to corrosion in metal components (like boilers) within a closed heating loop. However, modern “oxygen-barrier” PEX has largely mitigated this issue for potable water systems.

Frequently Asked Questions (FAQ)

1. Is PEX safe for drinking water?

Yes, absolutely. All PEX tubing sold in the United States must meet strict NSF/ANSI 61 standards for drinking water safety. Extensive testing has confirmed that PEX does not leach harmful chemicals into the water supply when installed correctly and used within its temperature ratings.

2. Can I connect PEX directly to my existing copper pipes?

Yes, you can easily transition between the two systems. Specialized transition fittings, often called “sharkbite” push-to-connect fittings or threaded adapters, allow you to join PEX to copper without soldering. This makes PEX an ideal solution for partial repairs or room additions.

3. How long does PEX plumbing last compared to copper?

While copper has a historical lifespan of 50+ years, modern PEX is projected to last between 40 and 50 years, with many experts believing it will exceed that timeframe. Since PEX has only been widely used in the US since the 1980s, we are still gathering long-term data, but current indications are extremely positive.

4. Does PEX affect the taste of the water?

Some users report a slight plastic taste when PEX is first installed. This is usually temporary and dissipates after flushing the system for a few days. Copper, conversely, can sometimes impart a metallic taste, especially if the water is acidic. In blind taste tests, most people cannot distinguish between water from properly flushed PEX and copper lines.

5. Can PEX be used for hot water lines?

Yes, PEX is rated for both hot and cold water applications. Standard PEX tubing can typically handle temperatures up to 200°F (93°C) at lower pressures, which is well above the standard residential water heater setting of 120°F–140°F. Just ensure you use the correct color-coded pipes (Red for hot, Blue for cold) to avoid confusion during future maintenance.

6. Why do some local building codes still restrict PEX?

Building codes vary by municipality. In the early days of PEX, some regions were slow to adopt it due to a lack of familiarity or concerns about early-generation materials. However, the International Residential Code (IRC) now fully accepts PEX. If you encounter restrictions, it is often an outdated local amendment that can be challenged with current manufacturer certifications.

Conclusion

The verdict in the battle of PEX vs Copper for domestic plumbing systems is clear: while copper remains a durable and respected material, PEX offers superior flexibility, freeze resistance, and cost-effectiveness for the modern homeowner. The ability to install faster, reduce leak points, and withstand harsh winter conditions makes PEX the logical choice for new constructions and repiping projects alike.

By choosing PEX, you are not just saving money on initial installation; you are investing in a system that demands less maintenance and offers robust performance for decades. However, always consult with a licensed local plumber to ensure your specific home environment and local codes align with your plans.

Did you find this comparison helpful in making your plumbing decisions? Share this article on Facebook, Twitter, or LinkedIn to help your friends and family navigate their own home improvement projects with confidence!

Leave a Reply