There is nothing more frustrating than watching water swirl slowly down your bathtub drain while a gurgling sound echoes through the walls of your home. This common nightmare often stems from improper air pressure balance within your plumbing system, specifically when dealing with multi-level structures. As a homeowner or DIY enthusiast tackling a renovation, understanding the correct piping for venting on plumbing two story unit with bathtub is not just about convenience; it is critical for preventing sewer gas leaks and ensuring your entire drainage system functions smoothly for decades.

In this comprehensive guide, we will demystify the complex world of Drain-Waste-Vent (DWV) systems. Whether you are building a new two-story unit or retrofitting an old one, getting the venting right is the difference between a plumbing system that sings and one that constantly complains. Let’s dive into the mechanics, codes, and practical steps to get your project done right.

Why Is Proper Venting Critical for Two-Story Units?

Before we pick up a pipe cutter, it is essential to understand why venting matters so much, especially in a two-story configuration. When water flows down a drain, it creates a vacuum behind it. Without a vent pipe allowing air to enter the system, this vacuum can suck the water out of your P-traps—the U-shaped pipes under your sinks and tubs that block sewer gases.

In a single-story home, this physics problem is manageable. However, in a two-story unit, the stack effect intensifies. Water dropping from the second floor gains significant velocity, creating stronger negative pressure that can easily siphon traps on the first floor if the venting is inadequate. According to general plumbing engineering principles, a properly vented system maintains atmospheric pressure within the pipes, allowing waste to flow freely by gravity without resistance.

Failure to adhere to these principles doesn’t just mean slow drains; it poses a health risk. Sewer gases contain methane and hydrogen sulfide, which can be hazardous in enclosed spaces. Therefore, the design of your piping for venting on plumbing two story unit with bathtub must prioritize air admission equal to the volume of wastewater being discharged.

What Are the Code Requirements for Bathtub Vents?

Every region has its specific plumbing code (such as the IPC – International Plumbing Code or UPC – Uniform Plumbing Code in the US), but the fundamental physics remain the same. For a standard bathtub, the trap size is typically 1.5 inches, and the drain pipe is usually 2 inches.

The Distance Rule

One of the most cited questions involves how far a trap can be from the vent. Generally, for a 2-inch drain line serving a bathtub:

- Maximum Distance: The trap arm (the pipe between the trap and the vent) cannot exceed 5 feet if the slope is 1/4 inch per foot.

- Slope Importance: If you increase the slope beyond 1/4 inch per foot, you risk “self-siphoning,” where the water moves too fast and pulls the trap seal with it, effectively negating the need for a distant vent because the water seals the pipe before air can break the seal—but this is risky and often not code-compliant for long runs.

Wet Venting vs. Dry Venting

In two-story units, space is often at a premium inside wall cavities.

- Dry Vent: A pipe that carries only air. This is the gold standard but requires more vertical shaft space.

- Wet Vent: A pipe that serves as both a drain for one fixture and a vent for another. For example, a bathroom sink drain can often act as the vent for the bathtub if sized correctly (usually upgraded to 2 inches). This is highly effective in two-story layouts where running a separate vent stack for every fixture is impractical.

For authoritative details on global plumbing standards and historical development of sanitation systems, you can refer to this Wikipedia overview on Plumbing.

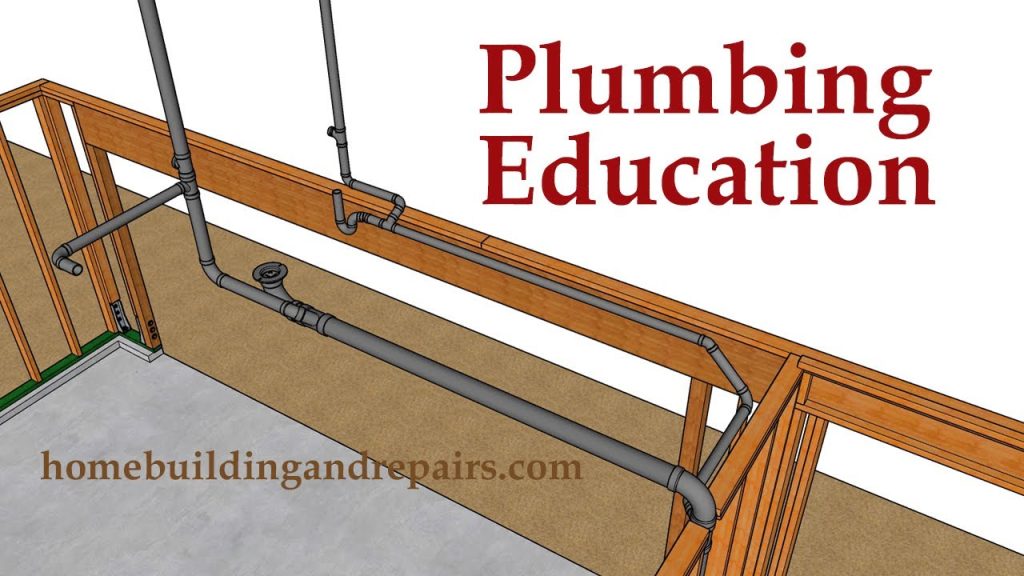

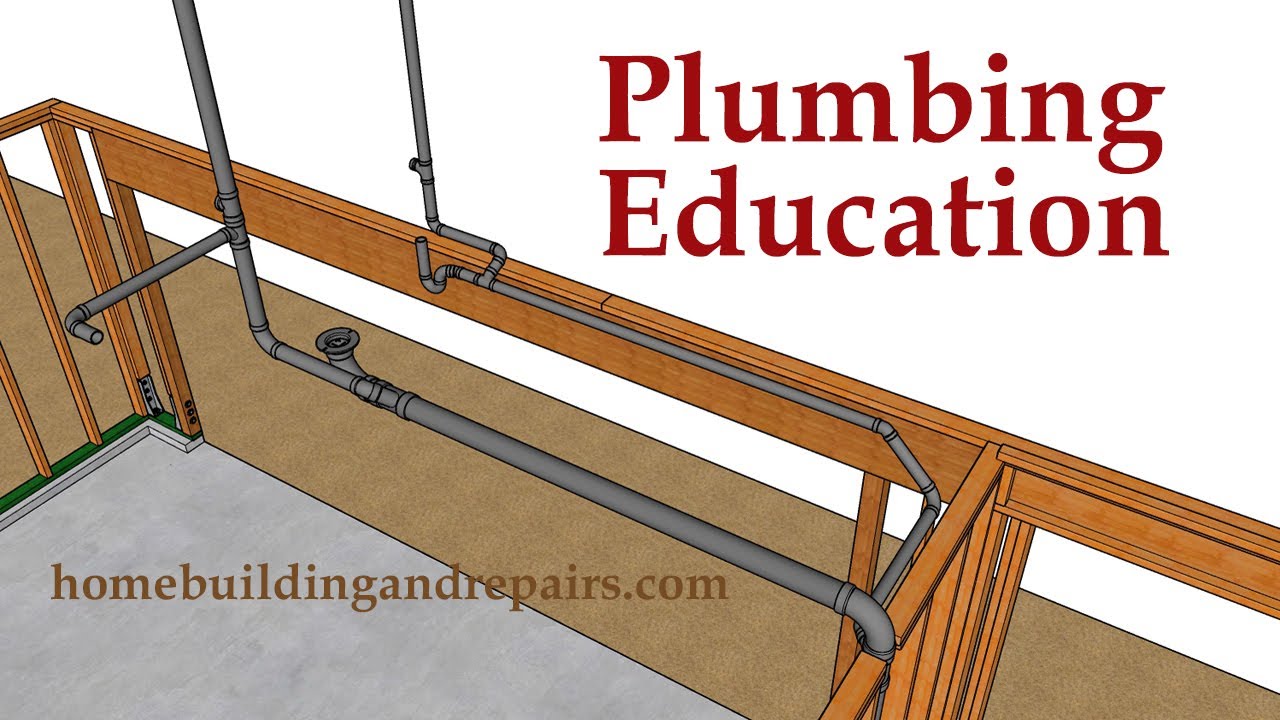

How Do You Design the Vent Stack for Two Stories?

Designing the main stack for a two-story home requires a strategic approach to handle the load from both levels simultaneously. The primary goal is to ensure that when the second-floor bathtub drains, it does not create a pressure wave that disrupts the first-floor fixtures.

The Main Stack Strategy

The most robust method is utilizing a continuous stack vent. This involves running a 3-inch or 4-inch soil stack vertically from the basement or crawl space, through the first floor, up to the second floor, and terminating through the roof.

- Connection Points: The second-floor bathtub connects to the stack via a sanitary tee.

- Offset Considerations: If the stack must offset (move horizontally) between floors to avoid a beam, strict code ratios apply. Generally, offsets below the lowest branch connection must be treated as horizontal drains, requiring their own re-venting.

- Roof Termination: The vent must extend at least 6 inches above the roof surface and be located at least 10 feet away from any operable window or air intake to prevent odor re-entry.

Comparative Analysis: Single Stack vs. Dual Stack

| Feature | Single Stack System | Dual Stack System |

|---|---|---|

| Cost | Lower material and labor costs. | Higher due to extra piping. |

| Space Required | Minimal; fits in standard 2×4 walls. | Requires more wall cavity space. |

| Performance | Good for small bathrooms; risky if oversized loads occur. | Superior airflow; handles high volume better. |

| Complexity | Easier to install in retrofits. | More complex planning required. |

| Best Use Case | Standard residential two-story units. | Large homes or units with multiple baths per floor. |

Step-by-Step Guide: Installing the Vent for a Second-Floor Bathtub

If you are ready to tackle the installation, precision is key. Here is a concrete, step-by-step tutorial for installing a dedicated vent for a second-floor bathtub using standard PVC piping.

Tools Needed:

- PVC pipe cutter or reciprocating saw

- Deburring tool

- PVC primer and cement (appropriate for your pipe schedule)

- Level (24-inch)

- Tape measure

- Safety gear (gloves, goggles)

Materials:

- 2-inch Schedule 40 PVC pipe (for drain/vent)

- 1.5-inch PVC pipe (for trap arm if applicable)

- Sanitary Tee (2x2x1.5 inch if reducing)

- P-Trap (1.5 inch)

- Pipe hangers

Installation Steps

- Measure and Cut the Trap Arm: Measure the distance from the bathtub drain outlet to the location where the vent will connect. Cut your 1.5-inch or 2-inch pipe accordingly. Ensure the cut is square. Use the deburring tool to remove any plastic shavings; rough edges catch hair and debris, leading to clogs.

- Establish the Slope: This is the most critical step. Lay the pipe on a flat surface and use your level. You must achieve a slope of 1/4 inch per foot.

- Calculation Example: If your pipe run is 4 feet long, the drop from the start to the end must be exactly 1 inch.

- Mark this slope on your framing studs before securing hangers.

- Install the Sanitary Tee: At the point where the vent rises, install a sanitary tee. Never use a regular tee for drainage turning upward; the sharp angle causes turbulence and clogging. The side inlet of the tee receives the bathtub drain, the bottom continues to the main stack, and the top goes up to the roof.

- Tip: Apply PVC primer (purple) first, let it dry for 5 seconds, then apply cement generously to both the pipe and fitting. Twist the pipe a quarter turn as you push it in to ensure an even seal. Hold for 15 seconds.

- Run the Vertical Vent: Connect a 2-inch pipe vertically from the top of the sanitary tee. This pipe must go straight up through the floor joists of the attic and terminate through the roof.

- Secure the pipe every 4 feet with pipe hangers to prevent sagging, which can collect condensation and block airflow.

- Connect the Bathtub Trap: Install the P-trap directly below the bathtub drain. Ensure the slip-joint nuts are hand-tightened plus a quarter turn with pliers—do not overtighten, or the plastic will crack. Pour 2 liters of water immediately after installation to test the seal and check for leaks. The water temperature should be ambient (approx. 20–25°C) to avoid thermal shock to fresh glue joints.

- Final Pressure Test: Before closing up walls, cap the open ends of the system and perform an air or water test. Fill the system with water to the highest point and watch for 15 minutes. If the water level drops, you have a leak.

Common Mistakes to Avoid in Multi-Level Venting

Even experienced DIYers make errors when dealing with piping for venting on plumbing two story unit with bathtub scenarios. Avoiding these pitfalls will save you thousands in repairs later.

- Improper Sizing: Downsizing a vent pipe to fit behind a stud is a major violation. A 2-inch drain generally requires a 2-inch vent (or 1.5-inch in specific wet vent scenarios allowed by code). Never go smaller than the trap diameter.

- Flat Vents: Horizontal vent pipes (before they rise to the roof) must still be sloped slightly upward toward the stack to prevent condensation from pooling and blocking the air passage.

- Ignoring Fixture Units: Every fixture has a “Drainage Fixture Unit” (DFU) value. A bathtub is typically 2 DFUs. Your main stack must be sized to handle the total DFUs of all connected fixtures on both floors. Overloading a 3-inch stack with too many fixtures on two stories can cause backpressure.

- Using Sharp Elbows: Always use long-sweep elbows (radius of curvature is larger) instead of sharp 90-degree elbows for horizontal-to-vertical transitions. Sharp turns increase friction and noise.

FAQ Section

1. Can I vent a second-floor bathtub through the wall instead of the roof?

Yes, this is known as an “Air Admittance Valve” (AAV) or Studor vent. It is a mechanical device that opens to let air in when negative pressure occurs but closes to prevent gas escape. While convenient for remodels where cutting the roof is difficult, many local codes restrict their use as the primary vent. They are best used as a secondary solution or where traditional venting is impossible. Always check your local jurisdiction.

2. What happens if the vent pipe is too small?

If the vent pipe diameter is insufficient, it cannot admit air fast enough to equalize the pressure created by flowing water. This results in “trap siphonage,” where the water seal in your P-trap is sucked out, allowing sewer gases into your home. You will also experience slow draining and loud gurgling noises.

3. How far can a bathtub be from its vent on the second floor?

For a standard 1.5-inch trap and 2-inch drain line, the maximum distance is typically 5 feet assuming a slope of 1/4 inch per foot. If you upgrade the drain line to 2 inches throughout the entire trap arm, some codes allow this distance to extend to 8 feet. Exceeding these limits requires adding an auxiliary vent closer to the trap.

4. Is wet venting legal for a two-story bathroom group?

Yes, wet venting is widely accepted in both IPC and UPC codes for bathroom groups. In a typical setup, the sink drain (which is used frequently) acts as the vent for the bathtub and toilet on the same floor. However, the piping must be sized up (usually to 2 inches) to accommodate both waste flow and air passage simultaneously.

5. Why does my bathtub gurgle when the toilet flushes?

This indicates a shared vent issue or a partial blockage. When the toilet flushes (a large volume of water), it creates a pressure wave. If the vent is blocked or undersized, that pressure seeks relief by pulling air through the nearest available opening—your bathtub trap. This causes the gurgling sound and threatens the water seal.

6. Do I need a different pipe material for venting vs. draining?

No, typically the same material is used for both. In modern residential construction, Schedule 40 PVC is the standard for both drain and vent lines. It is corrosion-resistant, smooth (reducing clogs), and easy to install. Cast iron is sometimes used for sound dampening in luxury multi-story units but is not strictly required for function.

Conclusion

Mastering the piping for venting on plumbing two story unit with bathtub is a challenging but rewarding endeavor that ensures the longevity and hygiene of your home’s plumbing system. By respecting the physics of air pressure, adhering to strict slope requirements, and choosing the right configuration between wet and dry venting, you can eliminate gurgling drains and foul odors forever. Remember, while DIY is empowering, plumbing codes exist for safety; when in doubt, consulting a licensed professional is always a wise investment.

Did you find this guide helpful for your upcoming project? Don’t keep this knowledge to yourself! Share this article on Facebook, Twitter, or LinkedIn to help other homeowners navigate their plumbing renovations with confidence. If you have specific questions about your setup, leave a comment below, and let’s discuss the best solutions for your home.

Leave a Reply