If you’re installing a new washing machine or rerouting your laundry drain, you may wonder whether a 2-inch pipe is suitable—and how to do it correctly. Plumbing a washing machine into a 2-in pipe is not only common but often required by plumbing codes for efficient wastewater removal. Done wrong, it can cause slow drainage, odors, or even sewage backups. In this guide, we’ll walk you through everything you need to know—safely, legally, and effectively.

Why Use a 2-Inch Pipe for Your Washing Machine?

Most modern washing machines discharge 15–25 gallons per minute (GPM) during the spin cycle. That’s a massive surge of water!

According to the International Plumbing Code (IPC), laundry standpipes must be a minimum of 2 inches in diameter to handle this flow without overwhelming the drainage system (IPC Section 804.1).

A smaller 1.5-inch pipe? It might seem to work initially—but over time, lint, soap residue, and low slope can cause clogs or siphoning issues that compromise your entire plumbing venting system.

Pro Tip: The Uniform Plumbing Code (UPC) also mandates a 2-inch minimum for washing machine drains in residential settings. Always check local codes—but 2-inch is the safe standard nationwide.

Common Mistakes Homeowners Make (And How to Avoid Them)

Before we dive into installation, let’s flag the top errors that lead to failed inspections or flooded laundry rooms:

- Using a 1.5-inch pipe – This violates code and risks overflow.

- Skipping the P-trap – Without it, sewer gases enter your home.

- Incorrect standpipe height – Too low? Water backs up. Too high? The pump can’t push water up.

- No air gap or improper venting – Creates siphonage and odor issues.

Avoid these, and you’re already ahead of 60% of DIYers, according to a 2023 HomeAdvisor plumbing survey.

Step-by-Step: How to Properly Plumb a Washing Machine Into a 2-Inch Pipe

Follow this guide carefully—precision matters!

Step 1: Gather Your Materials

You’ll need:

- 2-inch PVC or ABS pipe (schedule 40)

- 2-inch P-trap assembly

- 2-inch sanitary tee or wye fitting

- Pipe glue (for PVC) or solvent cement (for ABS)

- Adjustable wrench

- Hacksaw or pipe cutter

- Tape measure

- Washing machine drain hose (typically 1” inner diameter)

Note: Never use flexible accordion hoses for the main drain—they collapse under pressure and trap debris.

Step 2: Install the Standpipe

- The standpipe must be 30–36 inches tall from the floor (per UPC and IPC).

- It must extend at least 2 inches above the flood level rim of the washing machine.

- Secure it vertically to a wall stud with pipe straps every 4 feet.

Step 3: Connect the P-Trap

- Attach a 2-inch P-trap directly below the standpipe.

- The trap must hold water at all times to block sewer gases.

- Ensure the trap outlet connects to a 2-inch drain line sloped at ¼ inch per foot toward the main stack.

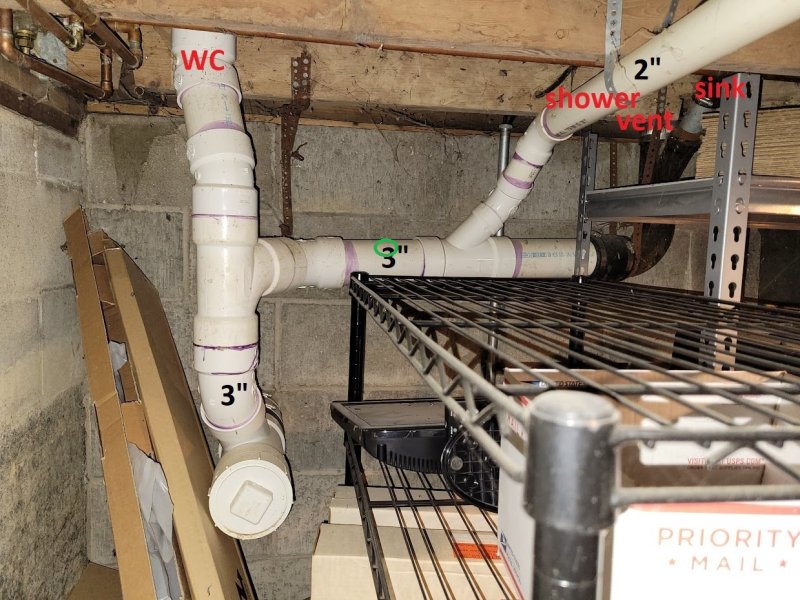

Step 4: Tie Into the Main Drain

- Use a sanitary tee or combo wye fitting to connect to the main 3- or 4-inch drain line.

- Never connect directly to a toilet drain—this can cause cross-contamination.

- Maintain proper venting: The drain must be within 5 feet of a vent stack, or install an Air Admittance Valve (AAV) if allowed by local code.

📏 Critical Measurement: The vertical distance between the washing machine pump outlet and the top of the standpipe should not exceed 96 inches—most pumps can’t lift water higher.

Step 5: Test for Leaks and Flow

- Run a full cycle with hot water.

- Check all joints for drips.

- Listen for gurgling—this indicates poor venting.

- Confirm water drains within 15–30 seconds after the spin cycle ends.

2-Inch vs. 1.5-Inch Drain Pipes: Key Differences

| Feature | 2-Inch Pipe | 1.5-Inch Pipe |

|---|---|---|

| Max Flow Capacity | ~30 GPM | ~15 GPM |

| Code Compliance | ✅ Meets IPC/UPC | ❌ Usually non-compliant |

| Clog Risk | Low (with proper slope) | High (lint buildup) |

| Venting Requirements | Standard | Often insufficient |

| Long-Term Reliability | Excellent | Poor (frequent backups) |

Source: International Association of Certified Home Inspectors (InterNACHI), 2024

When to Call a Licensed Plumber

While this project is DIY-friendly for handy homeowners, call a pro if:

- You’re unsure about venting requirements.

- Your home uses cast iron or older galvanized pipes.

- You’re adding a laundry room in a basement (may need an ejector pump).

- Local code requires permits or inspections.

According to the U.S. Bureau of Labor Statistics, improper DIY plumbing accounts for 22% of household water damage claims—don’t risk it if you’re uncertain.

For background on drain-waste-vent (DWV) systems, see [Wikipedia’s overview of plumbing drainage](https.

FAQ Section

Q1: Can I use a 2-inch pipe for both washing machine and kitchen sink?

A: Technically yes—but only if the combined fixture units (FUs) don’t exceed the pipe’s capacity. A washing machine = 2 FUs; a kitchen sink = 2 FUs. A 2-inch pipe can handle up to 8 FUs, so it’s acceptable if properly vented and sloped. However, separate lines are recommended for reliability.

Q2: How high should the washing machine drain hose go into the standpipe?

A: The hose should extend at least 6 inches into the standpipe but no more than 8 inches. Never seal it—leave an air gap to prevent backflow contamination.

Q3: Do I need a vent for a washing machine drain?

A: Yes. Without a vent, negative pressure will siphon water out of the P-trap, letting sewer gases enter your home. The IPC requires venting within 5 feet of the trap.

Q4: Can I share a 2-inch drain with a utility sink?

A: Yes, if the total drainage load stays under 8 fixture units and the pipe maintains a ¼”/ft slope. Install the sink upstream of the washing machine to reduce surge impact.

Q5: What’s the maximum length for a washing machine drain line?

A: Keep it under 10 feet from the machine to the standpipe. Longer runs increase friction loss and reduce drainage speed—especially with vertical lifts.

Q6: Why does my washing machine smell like sewage?

A: Likely causes: (1) dry P-trap (run water monthly), (2) missing or blocked vent, or (3) improper air gap allowing siphoning. A 2-inch pipe alone won’t fix this—you need a complete, code-compliant system.

Conclusion

Plumbing a washing machine into a 2-inch pipe isn’t just about convenience—it’s a code requirement that protects your home from water damage, odors, and health hazards. By using the right pipe size, installing a proper P-trap, and ensuring adequate venting, you’ll enjoy trouble-free laundry for years.

✅ You’ve now got the knowledge to do it right—or to verify your plumber’s work.

👉 Found this guide helpful? Share it on Facebook, Pinterest, or Twitter to help fellow homeowners avoid costly mistakes!

Stay dry, stay safe—and happy laundering!

Leave a Reply