If you’ve ever wondered why your pipes groan under pressure or why your water heater struggles during peak hours, you’re not alone. Understanding the most common loads found in plumbing systems are essential for homeowners, contractors, and engineers alike. These loads directly affect system performance, longevity, and even your monthly utility bills. In this guide, we’ll break down what these loads are, how they work, and why they matter—so you can make smarter decisions about your plumbing.

What Exactly Are “Loads” in Plumbing Systems?

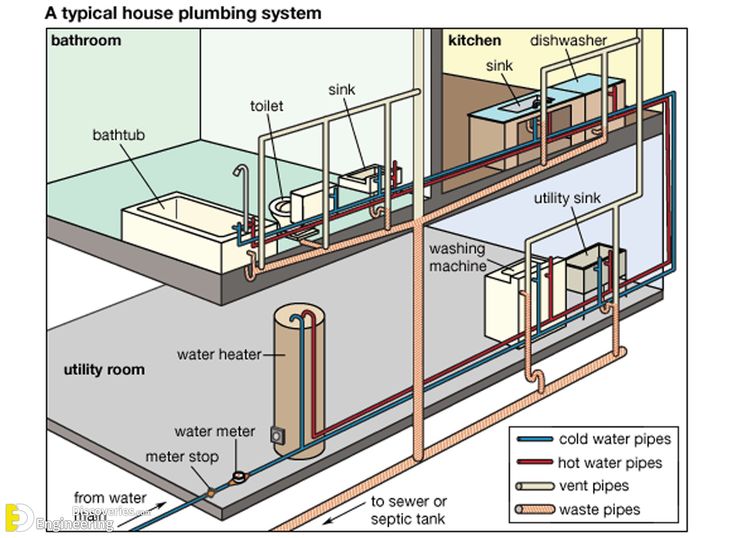

In plumbing terminology, a “load” refers to the demand placed on a system—whether it’s water usage, pressure, temperature, or waste flow. Think of it like electrical load: too much demand, and the system falters. Plumbing loads help engineers size pipes, select fixtures, and design systems that meet real-world usage without failure.

According to the International Plumbing Code (IPC), accurate load calculation is critical to prevent issues like low water pressure, pipe corrosion, or sewer backups. Misjudging these loads can lead to costly repairs and inefficiencies.

What Are the Most Common Loads Found in Plumbing Systems?

The most common loads found in plumbing systems are categorized into four main types:

- Water Supply Load

- Drainage/Waste Load

- Ventilation Load

- Thermal Load

Let’s explore each in detail.

1. Water Supply Load: How Much Water Is Needed?

This refers to the volume and pressure of potable (drinkable) water required by fixtures like showers, sinks, toilets, and appliances.

- Key Metric: Measured in gallons per minute (GPM) or fixture units (FU).

- Example: A standard shower uses 2.5 GPM, while a modern low-flow toilet uses 1.28 GPM per flush.

- Design Tip: The IPC uses fixture unit tables to convert fixture types into standardized demand values. For instance:Lavatory Sink0.50.51.0Shower1.01.02.0Kitchen Sink1.51.53.0Washing Machine2.0—2.0

💡 Pro Insight: Overestimating water supply load leads to oversized pipes and wasted energy. Underestimating causes pressure drops—especially during simultaneous use (e.g., shower + dishwasher).

2. Drainage/Waste Load: Managing What Goes Down the Drain

This load deals with the volume and velocity of wastewater flowing from fixtures to the sewer or septic system.

- Critical Factor: Pipe slope (typically ¼ inch per foot) ensures gravity-driven flow.

- Common Issue: Clogs occur when solid waste (from toilets) mixes with grease (from kitchens)—a frequent cause of backups.

- Code Requirement: The IPC mandates minimum pipe diameters based on expected waste load:

- Toilet drain: 3 inches minimum

- Sink drain: 1.25–1.5 inches

📊 Stat: The EPA estimates that 23,000+ sewer overflows occur annually in the U.S., many due to improper drainage load calculations.

For deeper context on wastewater systems, see Wikipedia’s overview on plumbing drainage .

3. Ventilation Load: The Invisible but Vital Component

Vent pipes allow air into the drainage system to prevent siphoning of trap seals (those U-shaped bends under sinks that block sewer gases).

- Why It Matters: Without proper venting, negative pressure can suck water out of traps—releasing foul odors and health hazards.

- Load Consideration: Vent sizing depends on total drainage fixture units. A 2-inch vent can typically serve up to 24 DFUs (Drainage Fixture Units).

- Modern Solution: Air admittance valves (AAVs) offer space-saving alternatives in tight installations—but aren’t allowed everywhere.

⚠️ Caution: DIY venting often violates code. Always consult local regulations.

4. Thermal Load: Hot Water Demand and Heat Loss

This refers to the energy required to heat water and maintain temperature in recirculation systems.

- Residential Impact: Water heating accounts for ~18% of home energy use (U.S. Department of Energy).

- Peak Load Scenario: Morning routines (shower + dishwasher + laundry) create high thermal demand.

- Efficiency Tip: Insulate hot water pipes to reduce heat loss by up to 25%. Use a recirculation pump with a timer to avoid wasting water while waiting for hot flow.

🔧 Step-by-Step Optimization:

- Calculate total hot water demand during peak hour (e.g., 6–8 AM).

- Size water heater accordingly (e.g., 50-gallon tank for 3–4 people).

- Install low-flow fixtures to reduce overall thermal load.

- Set water heater temperature to 120°F (49°C)—safe and efficient.

How Do These Loads Affect System Performance?

Ignoring proper load calculation leads to real-world consequences:

| Low shower pressure | Undersized supply lines | Re-evaluate fixture units |

| Gurgling drains | Inadequate venting | Add or resize vent stack |

| High energy bills | Excessive thermal load | Insulate pipes, upgrade WH |

| Frequent clogs | Overloaded drainage | Increase pipe slope/diameter |

Real-World Case Study: Fixing a Failing System in Austin, TX

A 2023 renovation in a 1980s Austin home revealed chronic low pressure and sewer smells. An engineer discovered:

- Original design used only ½-inch supply lines for a 3-bath home.

- No secondary vents for the kitchen island.

- Water heater was undersized (30-gallon for 5 occupants).

After recalculating the most common loads found in plumbing systems are, they:

- Upgraded main supply to ¾-inch copper.

- Installed an AAV under the island sink.

- Replaced heater with a 65-gallon hybrid heat pump model.

Result: 40% drop in water complaints, 20% lower energy use, and zero odor issues in 6 months.

FAQ Section

Q1: What does “fixture unit” mean in plumbing?

A: A fixture unit (FU) is a standardized measure of a plumbing fixture’s probable water demand or waste discharge. It simplifies load calculations by converting real-world usage into engineering values.

Q2: Can I calculate plumbing loads myself?

A: Basic estimates are possible using IPC tables, but accurate residential or commercial designs require a licensed plumber or engineer—especially for permits and code compliance.

Q3: Do tankless water heaters reduce thermal load?

A: Yes! Tankless systems only heat water on demand, eliminating standby heat loss. However, they must be sized correctly for simultaneous use (e.g., two showers + dishwasher).

Q4: Why do my pipes rattle when I flush the toilet?

A: This “water hammer” often stems from sudden pressure changes due to unbalanced supply and drainage loads. Installing water hammer arrestors usually fixes it.

Q5: Are plumbing loads different for commercial buildings?

A: Absolutely. Commercial systems face higher, more variable loads (e.g., restaurants, gyms). They require detailed hydraulic modeling and often use demand-based metering.

Q6: How often should plumbing loads be re-evaluated?

A: After major renovations, adding bathrooms, or installing high-demand appliances (e.g., Jacuzzi tubs). Even aging pipes may reduce effective capacity over time.

Conclusion

Understanding the most common loads found in plumbing systems are isn’t just for engineers—it empowers you to prevent costly mistakes, improve efficiency, and ensure your home runs smoothly. From water pressure to odor control, every load plays a role in your daily comfort and safety.

If this guide helped you grasp the hidden forces behind your faucets and drains, share it with a friend or on social media! A well-informed homeowner is the first line of defense against plumbing disasters. 💧🔧

Got questions? Drop them in the comments—we’re here to help!

Leave a Reply