If you’re planning a plumbing project and stumbled upon “oxygen barrier PEX,” you’re probably wondering: Can oxygen barrier PEX be used for plumbing? It’s a smart question—because while PEX tubing is widely used in residential plumbing, not all PEX types are created equal. Oxygen barrier PEX is engineered for specific applications, and using it incorrectly could lead to system damage or code violations. In this guide, we’ll clarify exactly where—and where not—to use oxygen barrier PEX, so you avoid costly mistakes and keep your system running smoothly for decades.

What Is Oxygen Barrier PEX?

Oxygen barrier PEX is a type of cross-linked polyethylene (PEX) tubing coated with a special layer—usually ethylene vinyl alcohol (EVOH)—that blocks oxygen from permeating through the pipe walls. This barrier is invisible to the naked eye but plays a critical role in certain heating systems.

Standard PEX (without the barrier) is permeable to oxygen, which isn’t a problem in potable water systems. But in closed-loop hydronic heating systems, oxygen infiltration can cause serious corrosion in ferrous (iron-based) components like boilers, pumps, and radiators.

According to the Plastics Pipe Institute (PPI), oxygen diffusion through non-barrier PEX in hydronic systems can accelerate corrosion by up to 300% over time.

Can Oxygen Barrier PEX Be Used for Plumbing? The Short Answer

Yes—but only for non-potable, closed-loop heating systems, NOT for standard household plumbing that delivers drinking water.

Here’s the key distinction:

| Potable Water Plumbing | ❌ No | Barrier material isn’t certified for contact with drinking water; may leach chemicals |

| Radiant Floor Heating | ✅ Yes | Prevents oxygen corrosion in metal components |

| Hydronic Baseboard Heat | ✅ Yes | Same as above—closed-loop, non-potable |

| Domestic Hot/Cold Water | ❌ No | Violates plumbing codes (IPC, UPC) and NSF/ANSI 61 standards |

The International Plumbing Code (IPC) and Uniform Plumbing Code (UPC) explicitly prohibit using oxygen barrier PEX for potable water unless the barrier material is NSF/ANSI 61-certified—which most are not.

⚠️ Important: Even if the tubing looks identical, using oxygen barrier PEX for drinking water can void warranties and fail inspections.

Why Oxygen Matters in Heating Systems (But Not in Water Lines)

In a closed-loop hydronic system, water circulates continuously through pipes, a boiler, and heat emitters (like radiators or in-floor tubing). If oxygen seeps into this loop:

- It reacts with iron and steel components → rust forms

- Rust clogs pumps, reduces heat transfer, and shortens equipment life

- System efficiency drops by up to 15–20% over 5–10 years (per ASHRAE studies)

In contrast, potable water systems are open to the atmosphere at faucets and fixtures. Oxygen is already present in tap water, so a barrier adds no benefit—and may introduce health risks if the coating isn’t food-safe.

For more on how oxygen permeation affects piping systems, see the Wikipedia entry on PEX tubing .

How to Identify Oxygen Barrier PEX

Not all PEX looks the same. Here’s how to tell:

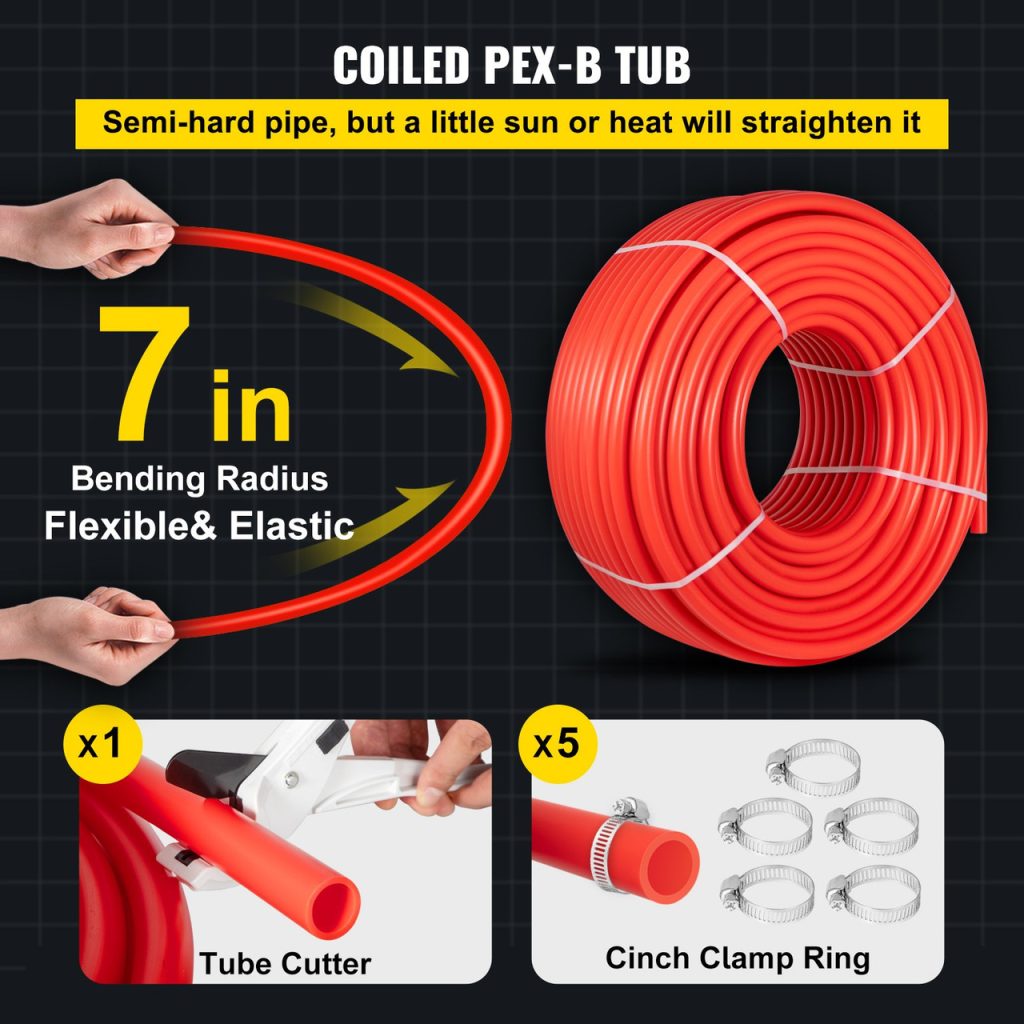

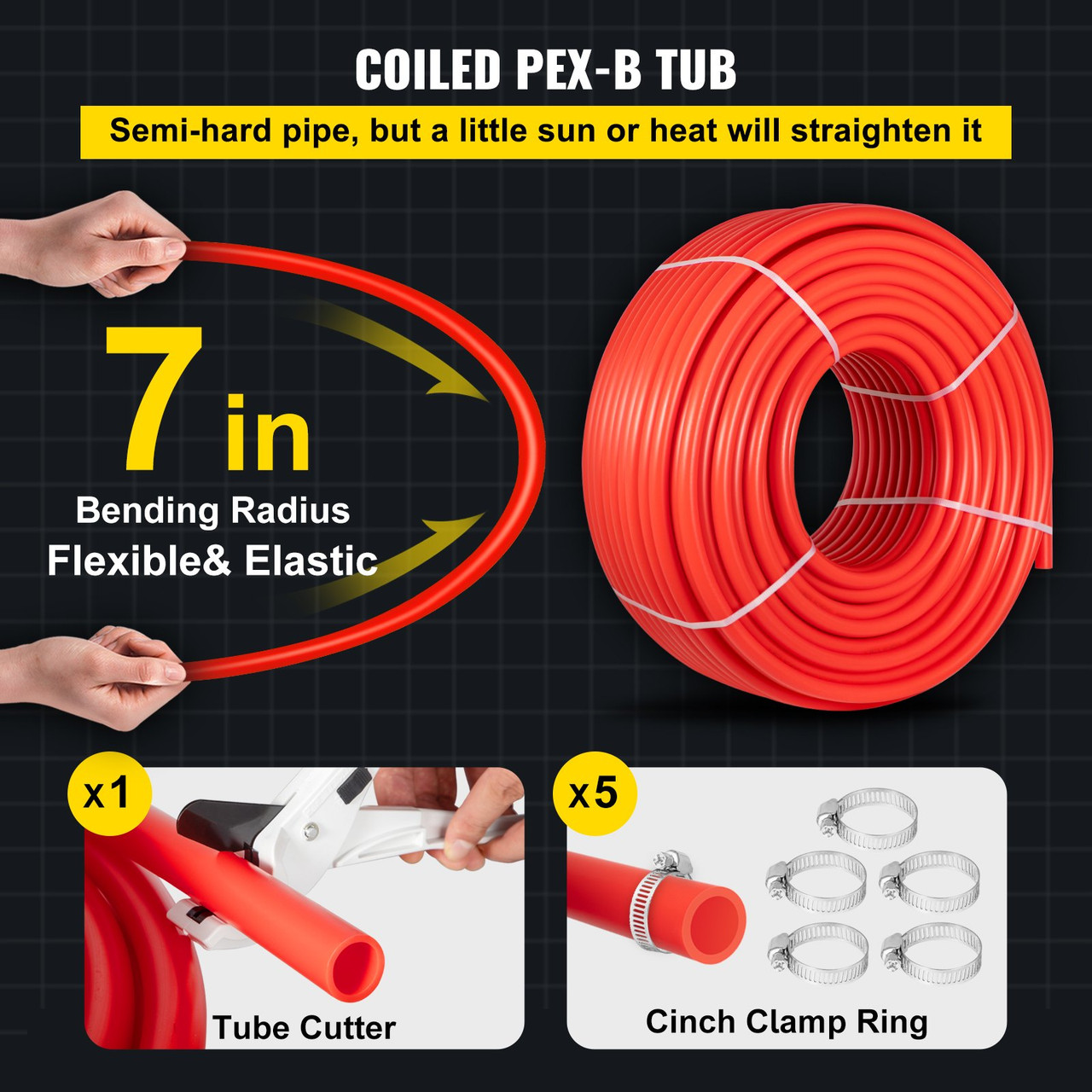

- Color: Often red, blue, or white with a distinct colored stripe (e.g., red stripe on white tubing)

- Labeling: Look for printed text like “O₂ Barrier,” “EVOH,” or “For Hydronic Use Only”

- Certifications: Should list ASTM F876/F877 and ASTM F1281 (standard for oxygen barrier PEX)

💡 Pro Tip: Always check the manufacturer’s specs. Brands like Uponor, REHAU, and Viega clearly label their barrier vs. non-barrier lines.

Step-by-Step: Installing Oxygen Barrier PEX in Hydronic Systems

If you’re using oxygen barrier PEX for radiant heating, follow these best practices:

- Verify Local Codes

Confirm your jurisdiction allows PEX in hydronic applications (most do, but check with your AHJ—Authority Having Jurisdiction). - Use Proper Fittings

Stick to manufacturer-recommended fittings (e.g., expansion rings for Uponor, crimp for SharkBite). Mixing systems can cause leaks. - Maintain Loop Integrity

Ensure the system is truly closed—no cross-connections to potable water. Install a backflow preventer if required. - Pressure Test Before Pouring

Pressurize the loop to 100 psi for 24 hours before embedding in concrete or under flooring. - Insulate Exposed Runs

Even in heating systems, insulate PEX in unconditioned spaces to prevent heat loss (use closed-cell foam sleeves).

Oxygen Barrier PEX vs. Standard PEX: Pros and Cons

| Oxygen Permeability | < 0.10 g/m³/day (very low) | ~0.80 g/m³/day (high) |

| Potable Water Safe? | ❌ No (unless certified) | ✅ Yes (NSF 61 compliant) |

| Best For | Radiant floor, baseboard heat | Drinking water, recirc lines |

| Cost | ~20–30% more expensive | Lower cost |

| Lifespan in Hydronics | 25–50 years (with protection) | Risk of corrosion in <10 yrs |

Common Mistakes to Avoid

- Using red oxygen barrier PEX for hot water lines → Not allowed by code; health and legal risk.

- Assuming “all PEX is the same” → Barrier and non-barrier serve different purposes.

- Skipping expansion loops → PEX expands when heated; without slack, stress cracks can form.

- Using non-oxygen-barrier PEX in a boiler system with cast iron → Leads to premature failure.

FAQ Section

Q1: Is oxygen barrier PEX safe for drinking water?

A: No, unless explicitly certified to NSF/ANSI Standard 61. Most oxygen barrier PEX is not approved for potable use due to the EVOH layer.

Q2: Can I use standard PEX for radiant floor heating?

A: Technically yes—but not recommended if your system contains iron, steel, or cast iron components. Oxygen ingress will cause corrosion. Use oxygen barrier PEX instead.

Q3: How do I know if my heating system needs oxygen barrier PEX?

A: If your boiler, pump, or radiators contain ferrous metals (iron or steel), you need oxygen barrier PEX. Systems with all-plastic or stainless-steel parts may not require it—but check manufacturer guidelines.

Q4: Does PEX-A, PEX-B, or PEX-C matter for oxygen barrier?

A: The PEX type (A/B/C) refers to cross-linking method and affects flexibility, not oxygen resistance. Oxygen barrier can be applied to any type—but PEX-A (e.g., Uponor) is most common in radiant applications due to superior kink resistance.

Q5: Will using the wrong PEX void my boiler warranty?

A: Yes. Many boiler manufacturers (like Weil-McLain or Burnham) explicitly require oxygen barrier tubing in their warranty terms. Using non-barrier PEX can void coverage.

Q6: Can I retrofit oxygen barrier PEX into an old system?

A: Yes—but flush the system thoroughly first to remove rust and debris. Also, inspect pumps and valves for existing corrosion before upgrading.

Conclusion

So, can oxygen barrier PEX be used for plumbing? The answer is nuanced: Yes for hydronic heating—no for drinking water. Getting this right protects your equipment, complies with building codes, and ensures decades of reliable performance.

If you’re installing radiant floor heating or upgrading a boiler system, oxygen barrier PEX is a smart, code-compliant choice. But for your kitchen sink or shower? Stick with standard, NSF-certified PEX.

✅ Key takeaway: Match the pipe to the purpose—never assume.

Found this guide helpful? Share it with a DIYer or contractor who’s planning a plumbing or heating project! A small detail like this can save thousands in future repairs.

Stay informed. Build smart.

Leave a Reply