You’ve bought your shipping container. You’ve painted it. You’ve even added windows and insulation. But now… how do you actually install plumbing in a shipping container? If you’re dreaming of a cozy tiny home, mobile office, or off-grid retreat — plumbing is the make-or-break step. Many people underestimate how different plumbing in a steel box is compared to a traditional house. Water pressure, drainage angles, pipe expansion, and condensation? They all behave differently in a metal structure. But don’t worry — you don’t need to be a licensed plumber to get this right. In this guide, we’ll walk you through how to install plumbing in a shipping container, step by step, using real-world solutions that work for homeowners, RV enthusiasts, and DIY builders across the U.S. Let’s turn your container into a fully functional, comfortable space — without the headaches.

Why Plumbing in a Shipping Container Is Different (And How to Handle It)

Before we jump into tools and pipes, let’s understand the challenge.

Shipping containers are made of corrugated steel, which conducts temperature and moisture aggressively. That means:

- Condensation can form inside walls, leading to mold if pipes aren’t insulated properly.

- Metal expansion/contraction with temperature changes can stress pipes and joints.

- Limited space means you can’t just run pipes through walls like in a conventional home.

- Drainage must be gravity-fed — no room for complex pump systems unless you plan to add one.

According to a 2023 survey by the Tiny Home Industry Association, over 68% of container home owners reported plumbing issues in their first year — mostly due to improper slope or lack of insulation. The fix? Planning ahead.

“Plumbing in a container isn’t harder — it just demands more precision,” says Mike Reynolds, a certified plumbing inspector and container home consultant in Texas. “Get the pitch right, insulate like your life depends on it, and test everything before you close the walls.”

Step 1: Plan Your Plumbing Layout (Before You Cut a Single Hole)

Ask yourself:

- Where will the water source be? (Municipal line, well, or tank?)

- Where’s the sewage exit? (Septic, municipal, or holding tank?)

- Will you have a kitchen, bathroom, or both?

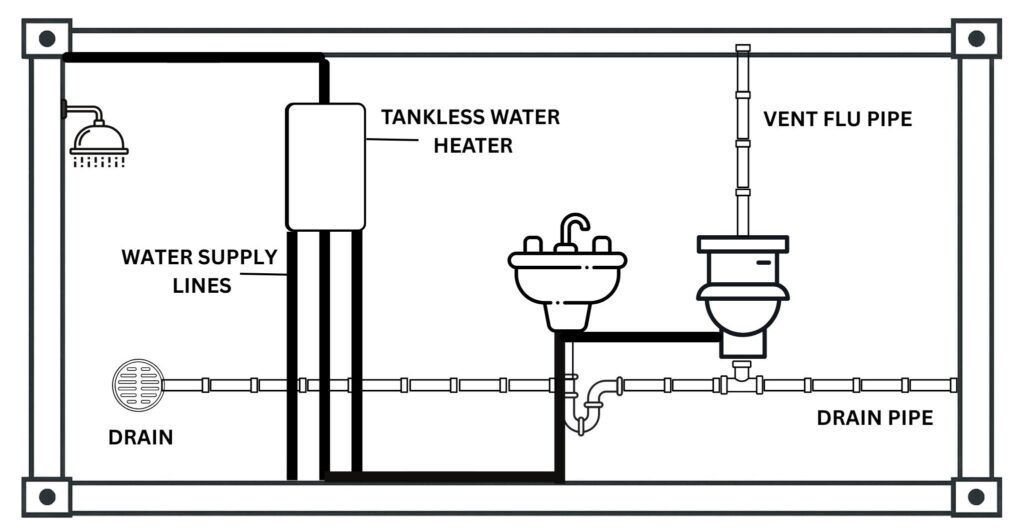

Pro Tip: Use graph paper or free apps like SketchUp Free to map out your layout. Here’s a sample for a 20ft container with a bathroom and kitchen:

| Shower | Rear left corner | PEX tubing | 1/4″ per foot |

| Toilet | Rear right corner | 3″ PVC | 1/4″ per foot |

| Sink (kitchen) | Front left | PEX + 1.5″ PVC | 1/4″ per foot |

| Water Heater | Under sink (wall) | PEX | N/A |

💡 Key Insight: Always run drain lines toward the center or rear of the container. That’s where you’ll likely connect to an external sewer or septic line. Avoid running pipes near the door — it’s a high-movement zone.

Step 2: Choose the Right Plumbing Materials

Not all pipes are created equal. Here’s what works best:

| PEX (Cross-linked Polyethylene) | Flexible, freeze-resistant, easy to install, no gluing | Can’t be exposed to UV light | Water supply lines |

| PVC (Polyvinyl Chloride) | Cheap, durable, easy to cut/glue | Brittle in cold temps, noisy | Drain lines only |

| CPVC | Handles hot water better than PVC | More expensive, requires solvent cement | Hot water lines |

| Stainless Steel (for supply) | Extremely durable, no corrosion | Expensive, hard to bend | High-end builds |

Recommendation for Beginners: Use PEX for water supply and PVC for drains. It’s the gold standard in container homes.

Fun fact: PEX was developed in the 1960s and now makes up over 90% of new residential plumbing in the U.S. (Source: Wikipedia – PEX )

Step 3: Insulate Everything — Yes, Even the Pipes

This is where 80% of DIYers fail.

Condensation forms when warm, moist air hits cold metal. Your pipes will sweat — and that sweat will rot your subfloor, rust your container, and grow mold.

Solution:

- Wrap all pipes with closed-cell foam insulation (1/2″ thickness minimum).

- Use reflective radiant barrier on the container walls before installing drywall or paneling.

- Seal all penetrations with silicone caulk or expanding foam.

Pro Tip: Run your drain pipes along the interior of the container wall, not the exterior. Why? Because exterior walls get colder — and condensation becomes worse.

Step 4: Install the Water Supply System

Tools Needed: PEX crimping tool, pipe cutter, PEX fittings, shut-off valves, water pressure regulator.

Step-by-Step:

- Install a pressure regulator (set to 40–50 PSI). Container homes often connect to low-pressure sources (like wells or tanks), and too much pressure can burst PEX joints.

- Run PEX from your water source (tank, well, or municipal line) to a manifold near your water heater.

- Use a 3/4″ main line, then branch off with 1/2″ lines to each fixture.

- Label each line with tape (e.g., “Kitchen Sink,” “Shower”) — it saves hours later.

- Install shut-off valves under every sink and near the toilet. You’ll thank yourself when a leak happens.

Pro Tip: Leave at least 6″ of slack in each PEX line. Steel expands and contracts up to 0.0000065 inches per degree Fahrenheit. That’s tiny — but over 40 feet of pipe, it adds up.

Step 5: Install Drainage and Venting (The Most Critical Part)

Drainage isn’t just about dumping water — it’s about air movement.

Without proper venting, your toilet will gurgle, sinks will drain slowly, and sewer gases will back up into your home.

How to do it right:

- Pitch your drain lines at 1/4 inch per foot — no less. Use a laser level or bubble level to check.

- Install a 2″ vent pipe that runs vertically from the main drain line to the roof. This equalizes pressure.

- Use a “wet vent” if space is tight: The kitchen sink drain can also vent the bathroom (if local code allows).

- Install a P-trap under every fixture. This holds water to block sewer gases.

Common Mistake: People try to vent through the side wall. Don’t. Always vent through the roof. Moisture and condensation will corrode the side wall seal.

According to the International Residential Code (IRC), all plumbing fixtures require a trap and vent. Violating this can void insurance and cause health hazards.

Step 6: Connect to Water and Sewer — Safely

You have three main options:

| Municipal Hookup | Permanent homes | Reliable, no maintenance | Requires permits, may need trenching |

| Septic System | Rural areas | Self-contained, long-term | Costs $5K–$15K to install |

| Holding Tank + Pump | Mobile/container RVs | Portable, no digging | Must empty every 2–7 days |

For most beginners: Start with a holding tank (like a 40-gallon black water tank) and a manual pump. It’s low-cost, portable, and lets you test your system before committing to permanent connections.

Install a level sensor in the tank — it’s a $20 gadget that prevents overflow.

Step 7: Test, Test, Test — Before You Close the Walls

Never skip this.

- Pressure Test: Close all valves, pressurize the system to 60 PSI, wait 15 minutes. If pressure drops >2 PSI, you have a leak.

- Flow Test: Run water at full blast through every fixture. Check for slow drains or gurgling.

- Smoke Test (for drains): Use a smoke machine (available at hardware stores) to see if sewer gases escape anywhere. If smoke leaks out — seal it.

Pro Tip: Take photos of your plumbing layout before you cover it with walls. You’ll need it for future repairs.

FAQ: Your Top 6 Questions About Plumbing in a Shipping Container

Q1: Can I use regular house plumbing in a shipping container?

Yes — but with modifications. Standard fixtures (toilets, sinks, showers) work fine. But you must insulate pipes, control water pressure, and ensure proper drainage slope. Don’t assume your home’s plumbing design will transfer directly.

Q2: Do I need a permit to install plumbing in my shipping container?

Almost always. Yes. Most U.S. municipalities require plumbing permits for any habitable structure, even if it’s on wheels. Check with your local building department. Skipping permits can lead to fines or being forced to remove your system.

Q3: How do I prevent pipes from freezing in winter?

Three ways:

- Insulate pipes with closed-cell foam.

- Install heat tape (thermostatically controlled) on exposed lines.

- Drain the system if you’re away for more than 3 days in freezing temps.

Tip: Use a 100W electric heater near the water heater to maintain ambient temp.

Q4: Can I install a shower in a 20ft container?

Absolutely. Many container homes include full showers. Just ensure:

- A sloped floor (1/4″ per foot) toward the drain.

- A waterproof membrane under the tile (or use a pre-formed fiberglass pan).

- At least 6′ of headroom — most containers have 8′ ceilings, so it’s doable.

Q5: What’s the average cost to plumb a shipping container?

For a basic setup (toilet, sink, shower, water heater):

- DIY: $800–$1,500 (materials only)

- Hired Pro: $3,000–$6,000

Pro tip: Buy bulk PEX and fittings from SupplyHouse.com or Home Depot Pro for 15–20% savings.

Q6: How long does plumbing installation take?

If you’re doing it yourself:

- Planning: 1–2 days

- Installation: 2–4 days

- Testing & Fixes: 1 day

Total: 4–7 days. Most pros can do it in 1–2 days.

Conclusion: You’ve Got This — Now Go Make It Happen

Installing plumbing in a shipping container isn’t magic — it’s method. By planning your layout, choosing the right materials, insulating aggressively, and testing everything, you’re not just adding pipes… you’re building comfort, safety, and value into your space.

Whether you’re creating a tiny home in the woods, a mobile office in the city, or a guest cabin by the lake — proper plumbing turns your container from a steel box into a true home.

Ready to take the next step?

👉 Share this guide with a friend who’s converting a container.

👉 Save this page for your next project.

👉 Comment below with your biggest plumbing question — we’ll answer it in our next update!

Your dream container home is closer than you think. One pipe at a time.

Leave a Reply