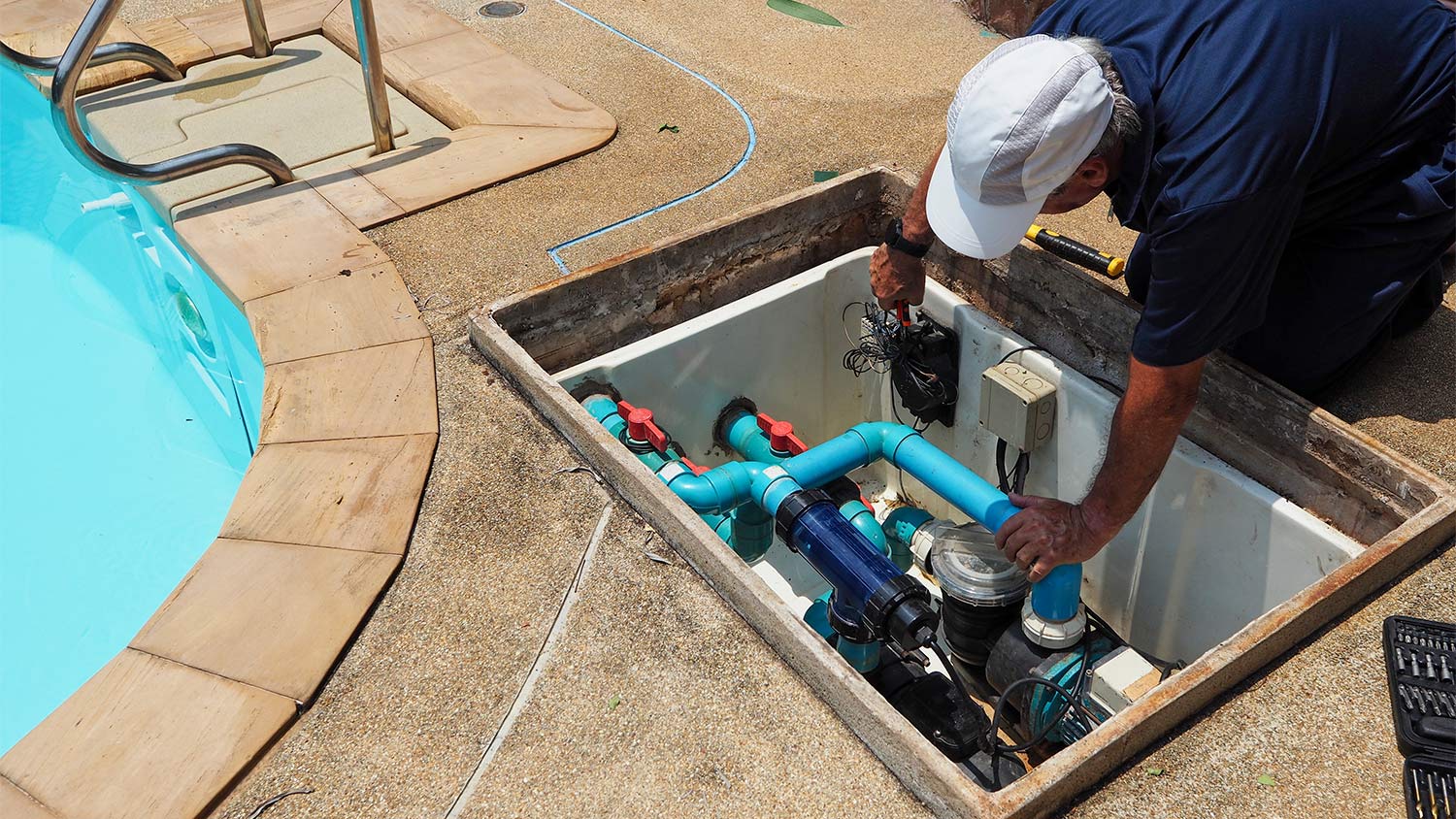

Installing the plumbing for an inground pool pump might seem intimidating—but with the right guidance, it’s a manageable DIY project that can save you hundreds of dollars. Whether you’re replacing an old pump or building a new pool system from scratch, knowing how to install the plumbing to an inground pool pump is essential for efficient water circulation, filtration, and long-term equipment health. Let’s walk through this process together—safely, clearly, and confidently.

Why Proper Pool Plumbing Installation Matters

A poorly installed plumbing system can lead to reduced water flow, air leaks, pump cavitation, or even complete system failure. According to the Association of Pool & Spa Professionals (APSP), over 60% of premature pump failures are linked to improper plumbing or suction-side issues. Getting it right from the start ensures your pool stays clean, your energy bills stay low, and your equipment lasts longer.

What Tools and Materials Do You Need?

Before turning a single wrench, gather these essentials:

- PVC pipes (typically 1.5″ or 2″ diameter, depending on pump specs)

- PVC primer and cement

- Pipe cutter or hacksaw

- Measuring tape

- Teflon tape

- Unions, elbows, valves (check valve, diverter valve if needed)

- Hose clamps (for flexible connections)

- Level and chalk line

- Safety goggles and gloves

💡 Pro Tip: Always match pipe size to your pump’s inlet/outlet ports. Most residential inground pools use 2-inch plumbing for optimal flow (per NSPI-1 standards).

Step-by-Step Guide: How to Install the Plumbing to an Inground Pool Pump

Step 1: Turn Off Power and Drain the System

Safety first! Shut off electricity at the breaker panel. Then, drain water from existing lines using drain plugs or by opening air relief valves. Never work on live electrical or pressurized plumbing.

Step 2: Position the Pump Correctly

Place the pump on a stable, level concrete pad within 10–20 feet of the pool. Closer = less friction loss. Ensure at least 18 inches of clearance on all sides for airflow and maintenance access.

⚠️ Note: The pump should sit below the pool’s water level for self-priming (gravity assist). If elevated, you’ll need a priming pot or manual priming each time.

Step 3: Measure and Dry-Fit All Pipes

Cut PVC pipes to connect skimmer(s), main drain, and return lines to the pump. Dry-fit everything first—no glue yet! This avoids costly mistakes. Use elbows and unions to allow future disassembly.

| Connection Type | Recommended Pipe Size | Purpose |

|---|---|---|

| Skimmer Line | 2″ | Surface debris removal |

| Main Drain | 2″ | Bottom circulation |

| Return Line | 2″ | Filtered water back to pool |

Step 4: Glue the Suction-Side Plumbing (Pump Inlet)

Start with the suction side (from pool to pump). Apply purple PVC primer, then clear cement. Join pipes quickly and hold for 30 seconds. Ensure no gaps—air leaks here cause loss of prime.

📌 Critical: Slope suction lines slightly downward toward the pump to prevent air pockets.

Step 5: Install a Check Valve (If Needed)

If your pump is above water level, install a spring-loaded check valve on the suction line just before the pump. This prevents water from draining back into the pool when the pump shuts off.

Step 6: Connect the Discharge Side (Pump Outlet)

Now glue the discharge line from the pump to the filter. Include a union fitting right after the pump outlet—this lets you remove the pump without cutting pipes later.

Step 7: Pressure Test Before Final Assembly

Cap the return line and fill the system with water. Turn on the pump briefly (with power restored cautiously). Check for leaks at all joints. Fix any drips immediately.

Step 8: Prime and Start the System

Remove the pump lid, fill the strainer basket with water, replace the lid, and turn on the pump. It should prime within 30–60 seconds. If not, check for air leaks or clogged lines.

For more on fluid dynamics in closed-loop systems, see Wikipedia’s entry on hydraulic circuits.

Common Mistakes to Avoid

- Using undersized pipes: Creates high head pressure, strains the motor.

- Skipping unions: Makes future repairs a nightmare.

- Gluing pipes while misaligned: Causes stress cracks over time.

- Ignoring local codes: Many municipalities require permits or inspections for pool plumbing.

🛠️ Real-World Example: A homeowner in Arizona saved $1,200 by DIY-ing their plumbing—but had to redo it twice due to air leaks from rushed dry-fitting. Patience pays off!

Flexible PVC vs. Rigid PVC: Which Should You Use?

| Feature | Rigid PVC | Flexible PVC |

|---|---|---|

| Durability | High (lasts 20+ years) | Moderate (5–10 years) |

| Leak Risk | Low (when glued properly) | Higher (clamp-dependent) |

| Vibration Absorption | Poor | Excellent |

| Cost | Lower | Higher |

Verdict: Use rigid PVC for permanent runs. Use flexible hose only for short pump-to-filter connections to absorb motor vibration.

How to Maintain Your Pool Plumbing After Installation

- Inspect unions and joints monthly for cracks or leaks.

- Lubricate O-rings on pump lids with silicone grease every 3 months.

- Winterize lines in cold climates to prevent freeze damage.

- Monitor pressure gauge—if it rises 10+ PSI above normal, your plumbing may be clogged.

FAQ Section

Q1: Can I install pool plumbing myself, or do I need a professional?

A: If you’re comfortable with basic plumbing and follow local codes, DIY is feasible. However, if your system includes complex multi-port valves, automation, or gas heaters, consult a licensed pool contractor.

Q2: How far should the pump be from the pool?

A: Ideally within 20 feet. Every extra foot increases friction loss, reducing efficiency. Keep it as close as practical while allowing maintenance space.

Q3: What size PVC pipe should I use for my inground pool?

A: Most residential inground pools use 2-inch PVC for both suction and return lines. Smaller pools (<15,000 gallons) may use 1.5″, but 2″ is recommended for future-proofing and better flow.

Q4: Why won’t my pump prime after plumbing installation?

A: Common causes: air leaks on suction side, clogged impeller, or pump above water level without a check valve. Re-check all glued joints and ensure the strainer basket is full of water before starting.

Q5: Do I need a permit to install pool plumbing?

A: In most U.S. states and counties, yes—especially if you’re modifying underground lines or electrical connections. Check with your local building department first.

Q6: How long does pool plumbing last?

A: Properly installed rigid PVC plumbing can last 20–30 years. Flexible hoses and rubber gaskets typically need replacement every 5–10 years.

Conclusion

Now that you know how to install the plumbing to an inground pool pump, you’re equipped to build a reliable, efficient, and long-lasting circulation system. Not only will this keep your pool sparkling clean, but it’ll also protect your investment in expensive equipment.

✅ Key Takeaways:

- Always dry-fit before gluing

- Use 2-inch PVC for optimal flow

- Install unions for easy maintenance

- Test for leaks before final startup

If this guide helped you, share it with fellow pool owners on Facebook or Pinterest! Got questions? Drop them in the comments—we’re happy to help you dive deeper into DIY pool mastery. 🏊♂️🔧

Leave a Reply