Ever had a leaky pipe or clogged drain above your ceiling—but no way to reach it without tearing down drywall? You’re not alone. Many homeowners face this frustrating dilemma, especially in finished basements, bathrooms, or kitchens with overhead plumbing. Knowing how to make an access panel for plumbing on the ceiling gives you safe, discreet entry whenever maintenance is needed—without damaging your walls or breaking the bank.

In this guide, you’ll get a step-by-step walkthrough, expert-backed tips, and everything you need to build a functional, code-compliant ceiling access panel that blends seamlessly with your interior.

Why Do You Need a Ceiling Access Panel for Plumbing?

Plumbing systems aren’t immune to wear and tear. According to the Insurance Institute for Business & Home Safety, nearly 25% of home insurance claims involve water damage from hidden leaks—many originating in concealed ceiling pipes. Without proper access, even minor issues can escalate into mold growth, structural rot, or expensive contractor visits.

A well-placed access panel:

- Prevents unnecessary demolition

- Meets building code requirements (most codes require access to shut-off valves and cleanouts)

- Saves hundreds in future repair costs

- Allows routine inspections

“Access panels are not just convenient—they’re a critical part of responsible home maintenance,” says Michael Chen, licensed plumber and founder of AquaSafe Solutions. “I’ve seen $300 leaks turn into $5,000 disasters because homeowners couldn’t reach the source.”

What Size Should Your Ceiling Access Panel Be?

The ideal size depends on what you’re accessing:

| Purpose | Recommended Panel Size |

|---|---|

| Shut-off valve or small joint | 12″ x 12″ |

| Drain cleanout or P-trap | 18″ x 18″ |

| Multiple pipes or complex junctions | 24″ x 24″ or larger |

Pro Tip: Always check local building codes. The International Residential Code (IRC) typically requires access to cleanouts and valves, but doesn’t specify exact dimensions—so err on the side of generosity.

Materials You’ll Need

Before you start, gather these supplies:

- Drywall (½” thickness recommended)

- Wood framing lumber (1×2 or 2×2 pine)

- Drywall screws (1¼”)

- Utility knife or drywall saw

- Tape measure & level

- Magnetic or snap-in access panel frame (optional but recommended)

- Paint or texture matching your ceiling

- Drywall compound & sandpaper

- [Optional] Hinges or removable fasteners for reusable access

Note: For moisture-prone areas like bathrooms, consider using mold-resistant drywall (often green-tinted).

Step-by-Step: How to Make an Access Panel for Plumbing on the Ceiling

Follow these precise steps to build a durable, nearly invisible panel:

Step 1: Locate the Plumbing Access Point

Use a stud finder and pipe detector (or consult your home’s blueprints) to identify the exact area needing access. Mark a square or rectangle at least 2 inches larger than the component you need to reach.

Step 2: Cut the Opening

- Use a drywall saw to carefully cut along your marked lines.

- Save the cut-out piece—it will become your panel door.

- Ensure edges are clean and straight for a snug fit.

Step 3: Build a Support Frame

- Cut four pieces of 1×2 lumber to match the inner dimensions of your opening.

- Screw them into the ceiling joists around the perimeter to create a sturdy lip.

- This frame prevents sagging and gives your panel something to rest on.

Step 4: Prepare the Panel Door

- Sand the edges of your saved drywall piece.

- If desired, attach lightweight trim or a commercial access panel frame (available at hardware stores like Home Depot or Lowe’s).

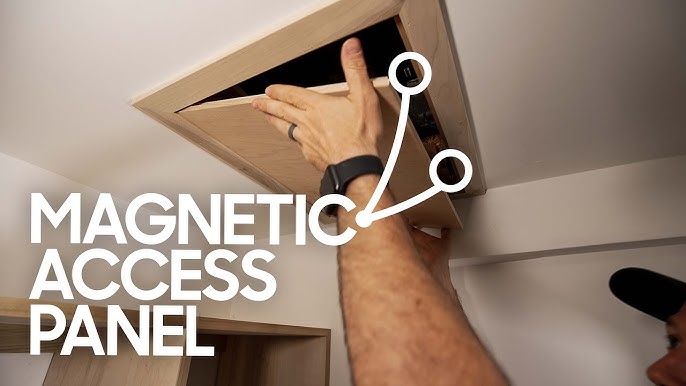

- For reusable access, install rare-earth magnets or plastic snap toggles instead of permanent screws.

Step 5: Install & Finish

- Place the panel into the frame.

- Secure lightly with removable fasteners or let magnets hold it in place.

- Apply joint compound around the seams, sand smooth, and paint to match your ceiling.

- For textured ceilings, use a spray texture can to replicate the finish.

⏱️ Time Estimate: 2–4 hours (including drying time for compound/paint).

💰 Cost: $20–$50 (vs. $200+ for professional drywall repair).

Pros vs. Cons of DIY Ceiling Access Panels

| Pros | Cons |

|---|---|

| ✔️ Full control over placement & size | ✖️ Requires basic drywall skills |

| ✔️ Blends invisibly when finished well | ✖️ Poor sealing may allow dust or pests |

| ✔️ One-time cost, lifetime access | ✖️ May void warranty if installed incorrectly in new builds |

To mitigate cons, always seal gaps with acoustic caulk (which remains flexible) and ensure the panel is flush to avoid visual detection.

Common Mistakes to Avoid

- Making the panel too small – You’ll struggle to fit tools or hands inside.

- Skipping the support frame – Leads to sagging or cracking over time.

- Using permanent screws – Defeats the purpose of easy access.

- Ignoring moisture risks – In humid areas, use moisture-resistant materials.

For more on building material safety standards, see the Wikipedia page on drywall, which covers composition, fire ratings, and moisture resistance.

FAQ Section

Q1: Are ceiling access panels required by code?

Yes—in most U.S. jurisdictions. The IRC (Section P2704.2) mandates access to cleanouts, shut-off valves, and traps. While it doesn’t dictate panel design, it does require “ready access,” which a removable panel satisfies.

Q2: Can I install an access panel in a popcorn ceiling?

Absolutely. Cut the opening carefully, then use a popcorn texture spray to match the finish after installation. Practice on scrap cardboard first to perfect your technique.

Q3: How do I keep the panel from falling?

Use a support frame screwed into ceiling joists. For extra security, add magnetic catches or friction-fit plastic clips designed for access panels.

Q4: What if my ceiling has recessed lighting nearby?

Avoid cutting near electrical boxes. Maintain at least 6 inches of clearance. If plumbing is directly above a light fixture, consider relocating the panel slightly or consulting an electrician.

Q5: Can I buy pre-made access panels?

Yes! Brands like Sequentia and ToughGard sell paintable, insulated panels with frames. They cost $30–$80 but save time and ensure professional results.

Q6: Will an access panel affect my home’s resale value?

Not if done correctly. In fact, savvy buyers appreciate accessible plumbing—it signals proactive maintenance. Just ensure it’s well-finished and unobtrusive.

Conclusion

Learning how to make an access panel for plumbing on the ceiling is a smart, cost-effective move for any homeowner. It protects your property, simplifies repairs, and keeps your ceilings intact—all while meeting legal and safety standards. With just basic tools and a few hours of work, you’ll gain peace of mind knowing help is always within reach—literally.

If this guide saved you a future headache, share it with a friend or pin it on Pinterest! Got questions? Drop them in the comments below—we love helping DIYers succeed.

🔧 Remember: A small panel today can prevent a flooded ceiling tomorrow.

Leave a Reply