If you’ve recently added an auger attachment to your John Deere 310SK backhoe loader—or are planning to—you’re likely wondering how to plumb hydraulic for auger on a JD 310SK without damaging your machine or compromising performance. Many operators struggle with incorrect hose routing, pressure mismatches, or flow issues that lead to poor auger function or even system failure. You’re not alone—and this guide is here to walk you through the process safely, efficiently, and correctly, whether you’re a seasoned technician or a first-time DIYer.

Why Proper Hydraulic Plumbing Matters for Your JD 310SK Auger

Hydraulic systems are the lifeblood of attachments like augers. On the JD 310SK—a versatile machine used in construction, landscaping, and utility work—improper plumbing can cause:

- Reduced auger torque, leading to stalling during drilling

- Overheating from restricted flow or incorrect valve settings

- Premature wear on pumps, seals, and hoses

- Safety hazards due to leaks or pressure spikes

According to a 2023 study by the Association of Equipment Manufacturers (AEM), 68% of hydraulic attachment failures stem from incorrect installation, not mechanical defects. That’s why getting the plumbing right isn’t just about performance—it’s about safety and longevity.

💡 Pro Tip: Always consult your JD 310SK Operator’s Manual (Section 7: Hydraulic System) before starting any modification. John Deere recommends using only OEM-approved fittings and hoses rated for 3,000+ PSI.

What Hydraulic Flow & Pressure Does the JD 310SK Provide?

Before connecting your auger, understand your machine’s hydraulic capabilities:

| Specification | JD 310SK (Standard Configuration) |

|---|---|

| Main Relief Pressure | ~2,300–2,500 PSI |

| Hydraulic Flow (Auxiliary) | ~17–21 GPM (depending on engine RPM) |

| Control Type | Pilot-operated joystick with optional third-function kit |

Most augers require 15–25 GPM at 2,000–3,000 PSI to operate efficiently. The JD 310SK’s auxiliary circuit typically meets this—but only if plumbed correctly.

⚠️ Warning: Never connect an auger directly to the main lift or curl circuits. These aren’t designed for continuous flow and can overheat.

For more on hydraulic fundamentals, see Hydraulic machinery on Wikipedia.

Step-by-Step: How to Plumb Hydraulic for Auger on a JD 310SK

Follow these steps carefully. Allow 2–3 hours for a first-time install.

Tools & Materials Needed

- Two hydraulic hoses (½” I.D., SAE 100R2AT, 3,000 PSI rated)

- Two flat-face quick disconnects (ISO 16028 compliant)

- Adjustable wrenches, torque wrench

- Thread sealant (Teflon-free hydraulic paste)

- Safety glasses & gloves

- Third-function valve kit (if not already installed)

🔧 Note: Many JD 310SK models don’t come with a dedicated third-function circuit. You’ll need to install one (e.g., WR Long, Cabi, or OEM John Deere kit).

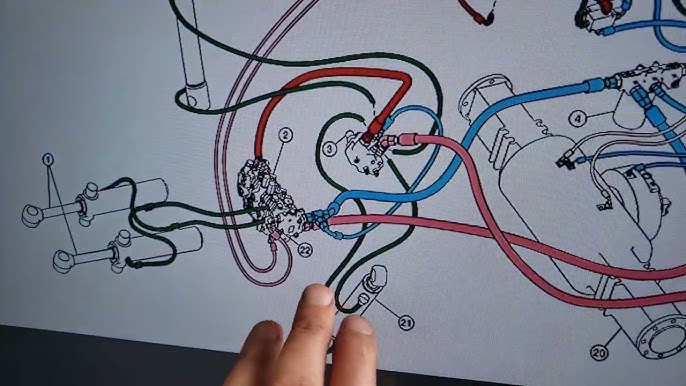

Step 1: Install a Third-Function Hydraulic Valve (If Missing)

- Locate the auxiliary hydraulic block near the control valve bank.

- Mount the third-function valve per manufacturer instructions.

- Connect it to the pump supply and tank return lines using provided fittings.

- Route control lines to the joystick (often requires drilling or adapter plate).

Typical cost: $400–$800 for a quality kit. Don’t skip this—direct tapping into existing lines voids warranties and risks system damage.

Step 2: Route Hydraulic Hoses to the Auger Mount

- Measure distance from valve outlet to auger motor inlet/outlet.

- Cut hoses to length (leave 10–15% slack for movement).

- Install crimped ends with ¼” NPT or ORFS fittings (match your auger ports).

- Secure hoses along the boom with nylon clamps—never let them dangle or rub metal.

✅ Best Practice: Use color-coded hoses (e.g., red for pressure, blue for return) to avoid reversal during reconnection.

Step 3: Connect to the Auger Motor

- Clean all ports with lint-free cloth.

- Apply hydraulic thread sealant to male fittings.

- Hand-tighten, then torque to 25–30 ft-lbs (check auger manual).

- Attach quick disconnects to hose ends.

❌ Common Mistake: Reversing A and B ports. This causes the auger to spin backward. Test briefly at low RPM before full operation.

Step 4: Bleed Air & Test Operation

- Start engine at idle.

- Cycle auger lever slowly 5–6 times to purge air.

- Check for leaks at all connections.

- Gradually increase RPM to operating speed (2,200 RPM).

- Verify smooth rotation and adequate torque in soil.

📊 Performance Check: A properly plumbed auger should drill a 12″ hole in compacted clay in under 45 seconds at 2,200 RPM.

Common Mistakes to Avoid

| Mistake | Consequence | Fix |

|---|---|---|

| Using undersized hoses | Flow restriction → overheating | Use ½” I.D. minimum |

| Skipping quick disconnects | Leaks during attachment changes | Always use ISO 16028 flat-face couplers |

| Ignoring relief valve settings | Motor stall or hose burst | Match auger pressure rating (usually 2,500 PSI) |

| Poor hose routing | Chafing → catastrophic failure | Clamp every 12″, avoid sharp bends |

FAQ Section

Q1: Can I use the bucket curl circuit to power my auger?

A: Technically yes, but not recommended. The curl circuit isn’t designed for continuous flow and lacks consistent pressure. You’ll risk overheating the hydraulic oil and damaging the control valve. Always use a dedicated third-function circuit.

Q2: What size hydraulic hoses do I need for a JD 310SK auger?

A: For most augers (9″–18″ diameter), use ½-inch inner diameter (I.D.) hoses rated for 3,000 PSI. Smaller hoses (⅜”) restrict flow and reduce torque.

Q3: My auger spins slowly—what’s wrong?

A: Likely causes:

- Air in the system (bleed again)

- Reversed A/B hoses (swap them)

- Low engine RPM (run at 2,000+ RPM)

- Clogged filter or worn pump (inspect hydraulic filters)

Q4: Do I need a flow control valve?

A: Only if your auger runs too fast or lacks torque control. Most modern augers include built-in relief valves. Adding an external flow control is optional but can improve precision in soft soils.

Q5: Can I install this myself, or hire a mechanic?

A: If you’re comfortable with hydraulic fittings and reading schematics, DIY is feasible. But if you’re unsure, hire a certified John Deere technician. Incorrect plumbing can cost thousands in repairs.

Q6: Where can I find a hydraulic schematic for the JD 310SK?

A: Official schematics are in the John Deere Technical Manual TM1331 (available via JD Parts or authorized dealers). Never rely on forum diagrams—they may be outdated or inaccurate.

Conclusion

Now you know exactly how to plumb hydraulic for auger on a JD 310SK—safely, correctly, and efficiently. Proper installation not only maximizes your auger’s performance but also protects your valuable machine from costly damage. Whether you’re digging fence posts, planting trees, or installing utilities, this setup will save you time and frustration on the job site.

🔧 Did this guide help you? Share it with fellow contractors or landscapers on Facebook, LinkedIn, or Reddit! And if you have questions, drop them in the comments—we’re happy to help.

Remember: When in doubt, consult a John Deere dealer. Your machine’s warranty and your safety are worth it.

Leave a Reply