If you’ve ever picked up a spool of solder at the hardware store, you might assume all solder is the same. But is there a difference between plumbing solder and electrical solder? Absolutely—and confusing the two can lead to serious health risks or project failure. Whether you’re fixing a leaky pipe or rewiring a circuit board, using the right type matters. Let’s break down exactly how they differ, why it matters, and what happens if you use the wrong one.

What Exactly Is Solder?

Solder is a fusible metal alloy used to join two or more metal surfaces. It melts at relatively low temperatures (compared to the metals being joined) and solidifies to create a strong, conductive, or watertight bond—depending on the application.

While both plumbing and electrical solder serve this basic purpose, their formulations are tailored to very different environments and safety standards.

Key Differences Between Plumbing Solder and Electrical Solder

1. Composition: Lead Content Matters

This is the most critical distinction:

- Electrical solder (especially modern types) is typically lead-free or contains only trace amounts of lead. Common alloys include tin-silver-copper (SAC305) or tin-copper. Older electronics may use 60/40 (60% tin, 40% lead) or 63/37 solder, but these are now restricted in many consumer applications due to RoHS (Restriction of Hazardous Substances) regulations.

- Plumbing solder, historically, often contained up to 50% lead for easier flow and stronger joints. However, since the U.S. Safe Drinking Water Act amendments in 1986—and stricter enforcement under the 2014 “Lead-Free” rule—plumbing solder used in potable water systems must contain less than 0.2% lead.

⚠️ Never use old leaded plumbing solder on electrical components—it’s inefficient and unsafe. Conversely, never use electrical solder on drinking water pipes, even if it’s lead-free, because it lacks the flux and mechanical strength needed for pressurized systems.

For more on solder alloys and regulations, see Wikipedia’s entry on solder.

2. Flux Type: Acid vs Rosin

Flux cleans metal surfaces and promotes adhesion. But not all fluxes are created equal:

| Solder Type | Flux Used | Why It Matters |

|---|---|---|

| Plumbing | Acid-based (e.g., hydrochloric or zinc chloride) | Highly corrosive; excellent for cleaning oxidized copper pipes but will destroy electronic circuits. |

| Electrical | Rosin-based (non-corrosive) | Mild, non-conductive residue; safe for delicate components. |

Using acid-core plumbing solder on a circuit board can cause short circuits, corrosion, or complete failure within hours or days.

3. Melting Point & Joint Strength

- Plumbing solder generally has a higher melting point (360–450°F / 182–232°C) to withstand hot water and pressure.

- Electrical solder melts at lower temps (300–400°F / 149–204°C), protecting heat-sensitive components.

Plumbing joints must endure constant water pressure (40–80 PSI) and thermal cycling. Electrical joints prioritize electrical conductivity and minimal thermal stress, not mechanical load.

4. Safety & Regulatory Compliance

The EPA and NSF International strictly regulate materials in contact with drinking water. Only NSF/ANSI Standard 61-certified solders are approved for potable water systems.

Electrical solder, meanwhile, must comply with RoHS and UL standards for flammability and toxicity in electronics.

Mixing them isn’t just ineffective—it can violate building codes or void product warranties.

Can You Use Electrical Solder for Plumbing? (Or Vice Versa?)

Short answer: No.

Here’s why:

- Electrical solder on pipes?

Even if lead-free, it uses rosin flux that doesn’t clean pipe oxides well. The joint may look sealed but can leak under pressure or fail over time. - Plumbing solder on electronics?

Acid flux will corrode copper traces, and lead content (if present) poses health risks during handling or disposal. Plus, the higher melting point can damage PCBs.

🔧 Real-world example: In 2021, a DIY homeowner in Ohio used plumbing solder to repair a smart thermostat. Within a week, acid residue ate through the circuit board, causing a short that tripped the home’s main breaker. Repair cost: $320—versus $8 for proper electrical solder.

How to Choose the Right Solder: A Quick Guide

For Electrical Work:

- Look for labels like “63/37,” “lead-free,” or “rosin core.”

- Diameter: 0.020″ to 0.031″ for fine electronics; 0.062″ for heavier wiring.

- Brands: Kester, MG Chemicals, or Multicore.

For Plumbing:

- Must say “lead-free” and “for potable water.”

- Often labeled “95/5” (95% tin, 5% antimony) or similar NSF-certified alloy.

- Use with plumbing-specific flux (paste or liquid).

- Always check for NSF 61 or UPC certification on the packaging.

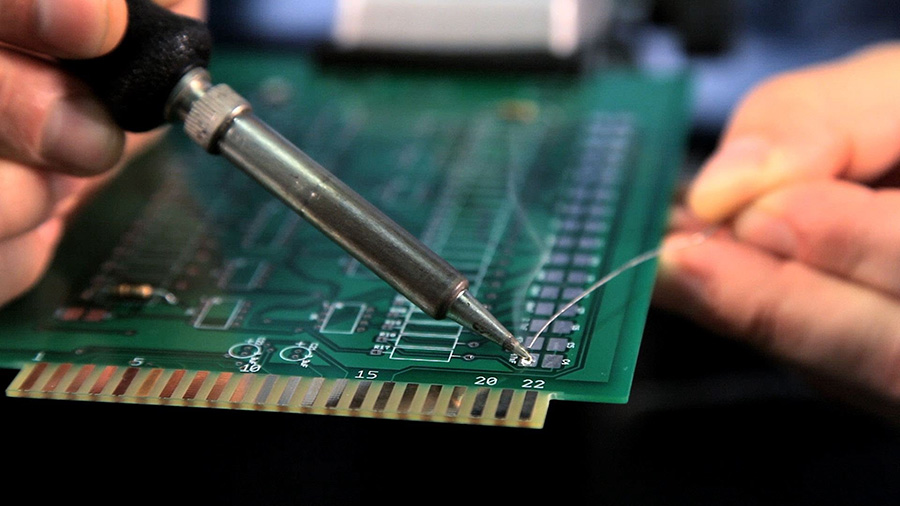

Step-by-Step: How to Solder a Copper Pipe (Correctly)

- Turn off water supply and drain the line.

- Clean pipe and fitting with emery cloth until shiny.

- Apply NSF-approved acid flux to both surfaces.

- Heat fitting evenly with a propane torch (not the pipe itself).

- Touch lead-free plumbing solder to the joint—capillary action will draw it in.

- Wipe excess with a damp rag once cooled.

- Flush system thoroughly before use.

💡 Tip: Use 2–3 inches of solder per ½-inch joint. Over-soldering causes blockages.

FAQ Section

Q1: Is all plumbing solder lead-free now?

A: In the U.S., yes—for pipes carrying drinking water. Federal law requires <0.2% lead content. However, older stock or industrial-grade solder (for non-potable systems) may still contain lead. Always check the label.

Q2: Can I use silver solder for electrical work?

A: Not recommended. Silver solder (used in HVAC or jewelry) has a much higher melting point (above 1,100°F) and lacks rosin flux. It’s overkill for electronics and can damage components.

Q3: What happens if I accidentally use plumbing solder on a circuit board?

A: Acid flux residue will corrode traces over time, leading to intermittent connections or total failure. Clean immediately with isopropyl alcohol and a soft brush—but replacement is often safer.

Q4: Is electrical solder safe for food-grade applications?

A: No. Even lead-free electrical solder isn’t certified for contact with consumables. Only use materials explicitly rated for food/water safety (e.g., NSF 61).

Q5: How can I tell plumbing and electrical solder apart?

A: Check the core:

- Plumbing solder: Often thicker, labeled “acid core” or “for copper pipe.”

- Electrical solder: Thinner, labeled “rosin core” or “electronics grade.”

When in doubt, don’t use it.

Q6: Are there eco-friendly solder options?

A: Yes! Lead-free electrical solders (like Sn-Ag-Cu) and bismuth-based low-temp alloys reduce environmental impact. For plumbing, tin-antimony or tin-copper alloys are common green alternatives.

Conclusion

So, is there a difference between plumbing solder and electrical solder? More than you might think. From chemical composition and flux type to safety regulations and performance demands, these materials are engineered for entirely different worlds. Using the wrong one isn’t just a minor mistake—it can compromise safety, legality, and your project’s longevity.

Now that you know the facts, you can solder with confidence—whether you’re patching a pipe or powering up a PCB.

👉 Found this helpful? Share it with a DIYer or electrician friend on Facebook, Pinterest, or Twitter! A quick share could save someone from a costly (or dangerous) error.

Stay safe, stay informed, and always use the right tool for the job.

Leave a Reply