Ever wondered why some buildings never face clogged drains, low water pressure, or foul odors—while others struggle constantly? The secret lies in smart basic principles of plumbing or sanitary designed of a building. Whether you’re a homeowner, architect, or aspiring engineer, understanding these fundamentals ensures safe, efficient, and code-compliant systems that protect both people and property. Let’s break it down in simple, actionable terms.

What Are the Basic Principles of Plumbing or Sanitary Design of a Building?

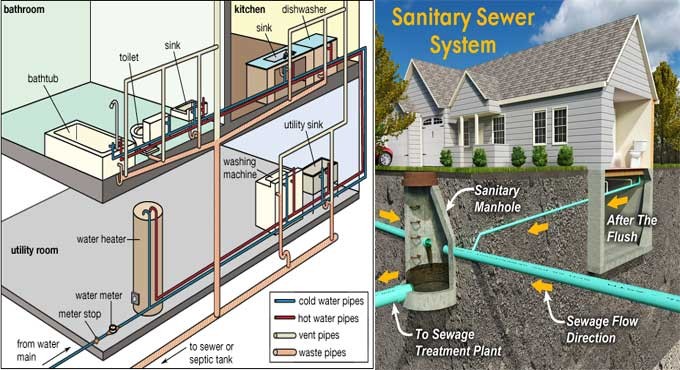

At its core, plumbing and sanitary design ensures the safe delivery of clean water and the efficient removal of wastewater—without contamination, leaks, or health hazards. According to the International Plumbing Code (IPC) and ASHRAE standards, a well-designed system must uphold five core principles:

- Adequate Water Supply

- Effective Drainage

- Backflow Prevention

- Ventilation of Drain Systems

- Compliance with Local Codes

Ignoring any of these can lead to serious issues: the CDC estimates that over 7 million Americans get sick annually from waterborne pathogens—many linked to poor plumbing practices.

💡 Fun Fact: Ancient Romans had advanced aqueducts and lead pipes—but lacked understanding of contamination. Modern plumbing fixes that with science-backed design.*

For deeper historical context on plumbing evolution, see Plumbing on Wikipedia.

Why Is Proper Sanitary Design Critical for Health and Safety?

Improper plumbing isn’t just inconvenient—it’s dangerous. Stagnant water breeds Legionella, blocked vents cause sewer gas buildup (methane and hydrogen sulfide), and cross-connections can poison drinking water.

A 2022 study by the American Society of Civil Engineers (ASCE) found that buildings with certified plumbing designs had 63% fewer water-related health complaints than those without.

Key risks of poor design include:

- Back-siphonage during water pressure drops

- Sewer gas intrusion due to dry P-traps

- Pipe corrosion from incompatible materials

- Flooding from undersized drains

5 Essential Principles Every Plumbing System Must Follow

1. Reliable Water Supply System

Your building must deliver clean water at consistent pressure (typically 40–80 psi). Use:

- Copper, PEX, or CPVC pipes for potable water

- Separate lines for hot and cold water

- Pressure-reducing valves if municipal pressure exceeds 80 psi

✅ Best Practice: Install a main shut-off valve within 5 feet of the water meter for emergencies.

2. Efficient Drain-Waste-Vent (DWV) System

This trio works together:

- Drain pipes carry wastewater away

- Waste pipes handle sewage from toilets

- Vent pipes equalize air pressure and prevent siphoning

All fixtures must connect to a P-trap—a U-shaped pipe that holds water to block sewer gases. Without it, your bathroom could smell like a subway station!

3. Backflow Prevention Is Non-Negotiable

Backflow occurs when contaminated water reverses into clean lines—often during firefighting or power outages. Solutions include:

- Atmospheric vacuum breakers (AVBs) for outdoor faucets

- Reduced pressure zone (RPZ) valves for irrigation or medical facilities

⚠️ The EPA mandates backflow prevention in all commercial buildings under the Safe Drinking Water Act.

4. Proper Ventilation Prevents System Failure

Every drain needs ventilation. Without it:

- Water drains slowly

- Gurgling sounds occur

- P-traps lose their water seal

Vent pipes must extend at least 6 inches above the roof and be minimum 1.25 inches in diameter (per IPC Section 904).

5. Code Compliance & Material Selection

Always follow:

- Local plumbing codes (often based on IPC or UPC)

- Material compatibility (e.g., don’t mix galvanized steel with copper—galvanic corrosion occurs)

- Slope requirements: Drainpipes need ¼ inch per foot of fall for proper flow

Common Mistakes in Plumbing Design (And How to Avoid Them)

| Mistake | Consequence | Solution |

|---|---|---|

| Undersized pipes | Low water pressure, slow drainage | Use pipe sizing charts based on fixture units |

| Missing cleanouts | Impossible to unclog lines | Install cleanouts every 50 ft in horizontal runs |

| Improper vent placement | Siphoned traps, odors | Follow IPC vent spacing rules (max 5 ft from trap) |

| Ignoring thermal expansion | Burst water heaters | Install expansion tanks on closed systems |

📊 Data Point: A 2023 NAHB report showed 41% of plumbing callbacks were due to venting errors—easily preventable with proper planning.

Step-by-Step: Designing a Basic Residential Plumbing System

- Calculate Fixture Units (FUs)

Each fixture has a FU value (e.g., toilet = 3 FUs, sink = 1 FU). Sum all FUs to size your main drain. - Determine Pipe Sizing

Use IPC Table 709.2:- 30–60 FUs → 3-inch building drain

- 61–252 FUs → 4-inch building drain

- Lay Out the DWV System

- Connect all fixtures to branch drains

- Join branches to a main building drain

- Install vents within 5 ft of each trap

- Install Backflow Devices

Required for:- Hose bibbs

- Irrigation systems

- Boiler feeds

- Test the System

- Air test: 5 psi for 15 minutes (no drop)

- Water test: Fill system to flood level for 15 minutes

FAQ Section

Q1: What’s the difference between plumbing and sanitary systems?

A: Plumbing includes both supply (clean water in) and sanitary (wastewater out). “Sanitary design” specifically refers to the drainage and sewage removal side.

Q2: Can I design my own plumbing system as a homeowner?

A: While DIY is possible for minor repairs, most U.S. jurisdictions require licensed professionals for new installations. Mistakes can lead to health hazards or failed inspections.

Q3: How often should plumbing systems be inspected?

A: Residential: every 2–3 years. Commercial: annually. Check for leaks, corrosion, and vent obstructions—especially after storms or renovations.

Q4: What causes slow drains in a new building?

A: Usually improper slope (less than ¼” per foot) or missing venting. Both prevent air from entering the pipe, creating suction that slows flow.

Q5: Are PEX pipes safe for drinking water?

A: Yes. PEX is NSF/ANSI 61-certified for potable water. It’s flexible, freeze-resistant, and widely used in modern U.S. construction.

Q6: What is a “fixture unit” and why does it matter?

A: A fixture unit measures a fixture’s water demand and drainage load. It’s the standard way to size pipes—ensuring your system handles peak usage without overflow.

Conclusion

Mastering the basic principles of plumbing or sanitary design of a building isn’t just about pipes and drains—it’s about protecting health, conserving water, and ensuring long-term functionality. From proper venting to backflow prevention, every detail matters.

Now that you understand these fundamentals, you’re better equipped to collaborate with contractors, inspect plans, or even pursue certification in building systems.

👉 Found this helpful? Share it on LinkedIn, Pinterest, or X (Twitter) to help fellow builders, architects, and homeowners build safer spaces!

Your building is only as strong as its hidden systems—design them right the first time.

Leave a Reply